Tekonsha Voyager Trailer Brake Controller w/ Custom Harness - 1 to 4 Axles - Proportional

Arrives before Christmas

Arrives before Christmas

with factory 4-Flat

with factory 7-Way

Will this fit?

To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

- All Info

- Reviews (751)

- Q & A (0)

- Videos (4)

- Photos

Tekonsha Trailer Brake Controller - TK98HR

- Electric

- Proportional Controller

- Up to 4 Axles

- Tekonsha

- Under-Dash

- Plug-In

- Under-Dash Box

- Single Trailer Only

- Indicator Lights

This proportional brake controller is designed to keep towing simple. Includes an LED braking indicator, a slide-bar manual override, and a knob to adjust braking power. Mounts easily within a 90-degree vertical range.

Features:

- Brake controller activates trailer brakes in proportion to your vehicle's braking action

- Automatically adjusts trailer's braking based on deceleration of tow vehicle

- Simple controls keep your settings within easy reach

- Gain setting lets you adjust the amount of power sent to the trailer's brakes

- Slide-bar manual override allows you to control trailer sway or stop in emergencies

- Sensitivity knob lets you set initial braking power and aggressiveness for smooth, safe braking

- Green LED on the top of the module monitors a secure connection with trailer

- Glows red to indicate that trailer brakes are being activated

- Quick and easy installation with included bracket and hardware

- 90-Degree vertical mounting range - must be horizontally level and parallel to direction of travel

- No need to wire into your vehicle - custom-fit harness lets you plug in and go

Specs:

- Application: trailers with up to 4 axles (8 brake assemblies)

- Compatible with electric brakes only

- Dimensions: 5" long x 3" wide x 1-1/2" tall

- Mounting: between -20 degrees and 70 degrees in the vertical plane

- Warranty:

- Limited 5-year on brake controller

- Limited 1-year on wiring harness

Power and Sensitivity Adjustment

Once the brake controller is installed, you can use the knob on the right side of the unit to adjust the gain (also known as output). Gain lets you set the maximum amount of power that will be applied to your trailer's brakes. You want to set it as high as you can without locking up the brakes. Typically, this setting is only readjusted when you experience changing road conditions or if you switch over from a heavy, loaded trailer to a much lighter, empty trailer, or vice versa.

You can fine-tune the gain by adjusting the sensitivity of the internal sensor using the knob on the left side. This controls the aggressiveness of your trailer's braking, meaning how quickly the brakes reach the maximum braking level. You can adjust this when you're towing heavy loads and you need more umph to bring your trailer to a stop. Your tow vehicle doesn't need that much power to brake in time, but your heavy trailer does. A high sensitivity level will get the braking power to your trailer brakes faster and with more intensity so that it doesn't push your tow vehicle forward.

LED Indicator

Keeping with its simple design, the Voyager will not overwhelm you with information. An LED indicator on the top of the unit lights up green to show that your trailer is securely connected to your tow vehicle. The LED indicator will change to red when the brakes on your trailer are activated.

During installation and setup, this light is also used to ensure that the Voyager will be able to function correctly. Proper leveling of the internal sensor is crucial to the operation of this brake controller. When the sensor is level, the LED will change to a shade of orange.

Simple Installation

The Voyager is designed to be mounted in your cab at a vertical angle that is between -20 degrees and 70 degrees. The brake controller needs to be horizontally level and parallel to the direction of travel in order to function properly.

To connect the Voyager, just plug the included harness into your vehicle. The other end plugs into the controller - no hardwiring required.

Once the controller is mounted and connected, you must level the internal sensor. First, set the overall power to the maximum using the knob on the side of the controller. Then, while pressing the tow vehicle's brake pedal, adjust the level knob on the other side of the brake controller (this is the same knob that is used to fine-tune the power output) until the LED monitor is a shade of orange.

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake controller installation kit (ETBC7 - sold separately).

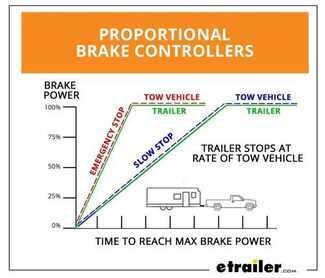

Proportional Braking

The Tekonsha Voyager brake controller comes equipped with proportional braking to give you the best towing experience. Proportional braking means that your trailer brakes mimic your tow vehicle's brakes. If you slam on the brakes in your vehicle, your trailer brakes will activate with the same intensity; if you brake lightly, your trailer brakes lightly too. The trailer's braking is in proportion to your vehicle's braking. This saves wear and tear on the tires and the brakes on both your vehicle and trailer.

The Voyager uses a pendulum system to sense how your vehicle is braking so it can send the right amount of braking power to your trailer. It measures the inertia of your tow vehicle and activates the trailer's brakes to slow at the same rate. The result is uniform braking across your towing setup. No push-pull action - just smooth, proportional braking every time.

9030 Tekonsha Voyager Electric Brake Controller - 1 to 4 Axles - Proportional

303600 Tekonsha Brake Control Wiring Adapter with 2 Plugs

Replaces Tow Ready 20272

Replaces 3036-P

Installation DetailsCalifornia residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Install: Tekonsha Voyager Trailer Brake Controller on a 2014 Ford F-150

Today on our 2014 Ford F150, we'll be installing the Takonsha Voyager Brake Control for 1 to 4 axles, part number 39510. We'll also be using the etrailer ETBC7 installation kit for brake controllers. With our power hooked up to our battery and our trailer hooked up to our brake controller, you can see we have a green light there. That means we have power going to our brake controller. This is our pendulum adjustment so when you level out your brake controller, you'll adjust that, and your power adjustment is on the side here. When you use your manual override, it will go from green to red so you know it's working. As you see, our truck is equipped for a 4-flat here on the back of the vehicle, and it is in a bracket. We're just going to go ahead slide that out of the bracket and tuck it behind our hitch, that way we can start to install our 7-way plug.

We'll go ahead and tuck it back here. Now, we need to go ahead and mount our 7-way here to the back of our vehicle. It does some with a bracket. As you can see, it's at a 90 degree angle and there's no where to mount it right here. We're just going to go ahead and bend this flat in a vice and go ahead and mark our holes right here, drill 2 holes, and then, we can mount our bracket and our 7-way here to the back of our truck.

We're going to go ahead and hold it up here against our bracket from the factory, mark our holes, and then go ahead bring our bracket down and drill out 2 holes. Now, we'll go ahead and take out bracket, feed our wires through it, and feed our 7-way to it. It does come with the necessary hardware needed to attach it. Just run the bolt through, loosely install the nut with the star washer built into it, get all 4 of those started, and then tighten them down. Now that we have those hand tight, we'll go ahead and take our small flat-bladed screwdriver and tighten these down. Now, we'll go ahead and bring out bracket up, line it up with our holes, and put our hardware through.

As you see, it's is angled out a little bit. We're going to go ahead and turn this out just a tad so it will fit flush up against here and clear our hitch. Now, we can go ahead and tighten those down. As you can see, nice and secure here on the back of our truck. Now, we can start with out wiring. Here's our 4-flat coming from our 7-way connector that we just put on, and we will be plugging it in here into the factory 4-way.

As you can see, the Ford 4-flat here is pretty thick. We're going to go ahead and trim back the rubber on this just so we can get a good connection. You see here that it exposes the terminals, and we can plug in our 4-flats together. We're going to use some dielectric grease, part number 11755, just to protect our connections from corrosion over time. All you have to do is put a dab on each terminal, and then, we can go ahead and plug them together. Press them in nice and tight, and we're actually going to go ahead and run a zip tie around this connection just to hold into place as another layer of protection to hold everything together. We'll trim off our excess zip tie, and then, we're going to go ahead and wrap that up with some electrical tape just to give it another layer of protection. There is a factory dust cap here that comes with the factory wiring. We'll just go ahead and snip that off as we will not be reusing it. Now that the connection is nice and secure, we can go ahead and work with our purple and white wire. Our purple wire will now be use . That's usually used for the reverse light circuit on your trailer. In this application, we will not be using it. The white wire is just the ground. We'll find a nice suitable location for the ground and attach it to the frame with a self-tapping screw that comes with our installation kit. Now before we run our wires, we're going to go ahead and wrap the bundle up with some electrical tape to clean up the install look and to protect the wires here at the rear of our vehicle while we still have access to them. Then, we'll go ahead and wrap the rest up once we make our final connections. Now, we'll go ahead and ground our white wire. We'll take our white ground wire that has the ring terminal on it and feed it up here over the frame just so we have some attachment points here, and we're going to ground it right here to our frame. We'll go ahead and use the larger self-tapping screw that comes with the kit and run that in. Now that that's attached, we can go ahead and make our final connections here to our black and blue wires. Now, we'll go ahead and take our gray duplex cable that come with our ETBC7 kit, and we're just going to go ahead an split the sheathing off here at the very end so that we can get access to our black and white wires on the inside. We'll go ahead and trim off that. Now, we're going to go ahead and strip the wires back here. We can go ahead and take this to the back of our truck and make our connections. Before we make our connections to our blue wire and black wire, we're just going to go ahead and snip this purple wire short. We'll go ahead and bring our duplex cable in. The black wire will go into the black wire coming out of our 7-way. We'll feed that into our butt connector. We'll go ahead and get a good crimp on those. We'll pull back on it to make sure you get a good connection, and then, our white wire will go into our blue wire. Eventually, our black wire will get ran into our engine compartment for our 12-volt and our white wire, which is connected to the blue wire, will get ran back inside and will connect to the blue wire on our brake controller, and that will be our brake signal coming from the brake controller back to our 7-way and to the trailer. Make sure you get a good crimp on those. Now, we'll go ahead and wrap these connections up with electrical tape along with the rest of our bundle. Now that we have everything wrapped up, we'll go ahead and use some zip ties. Now, we'll go ahead and take the other end of our duplex cable, run it up here over the frame and give it one more zip tie, and then, we can start running it down the length of our vehicle. Now, we'll go ahead and trim our zip ties off to clean up our install look. Now as you see here, we ran our duplex cable inside the frame. You can take a stiff piece of wire or a coat hanger, you can run it into your frame and then tape the duplex cable through it. You can run it all the way down the frame up towards the front wheel. As you can see, we came out of the frame right here in this hole, and then, we're going to follow this factory wiring harness into the engine compartment. You always want to stay away from any moving components such as suspension or any excess heat such as the exhaust or the engine when you get into the engine compartment. We'll go ahead and just attach a couple zip ties here to hold our wire up, and then, we can go up into the engine compartment and continue our installation. I'm just going to take a razor knife and cut down the middle of the sheathing. You just want to be careful when doing this. You want to split it from as far down as possible when you have it ran inside to the very end. Our black wire will go over to the driver side of the engine compartment and then our white wire will get ran inside through the firewall. Now before we connect our black wire to our battery, we're going to go ahead and run it through one of the breakers that comes with our kit. You'll get a 20, 30, and 40-amp breaker. The 40-amp breaker will be for our 12-volt power. Our black wire coming from the rear of the vehicle to the front will go into that here on the silver side, and then, it'll have a jumper wire coming from the copper side to the positive post on the battery. For the brake controller power, we'll be using the 20-amp breaker that comes with our kit, and we'll run the power wire from our brake controller back out through the firewall, through the silver side of our breaker, and then have a wire coming from the copper side to the positive side of our battery. We'll go ahead and use self-tapping screws here. I'm going to go ahead and attach these to the firewall right here. Now, we'll go ahead and overlap the middle connections points for our breakers and install our 2nd one. Then, we'll go ahead and install out last one, and now, our breakers are nice and secure here on the firewall. Now, we'll go ahead and run the black wire over here. We'll zip tie it to the firewall where we can, and then, we'll connect it to our 40-amp breaker here and then make our wire coming from the copper terminal her to the battery. We won't hook our connection up yet, but we will just run it over here because hooking it up to our battery will be the last step in installing our brake controller. Now, we'll go ahead and measure our black wire out, and it's going to this 40-amp breaker right here. Make sure you give yourself enough and cut the excess wire. Hold onto the wire as we will be using it going from the copper terminal to our battery. We'll go ahead and strip back our black wire and add on one of the small ring terminals that comes with our install kit. Make sure you get a nice crimp on that, and then, we'll take the nut off the silver terminal and install it onto there. We can go ahead and re-install our flat washer and our nut once we get our ring terminal onto our stud. Now that we have that one on there loosely, we're going to go ahead and take that piece of black wire that we have excess of, trim back one side, put another small ring terminal on it, and attach it here to the copper post. We'll add on our wire and re-install the star washer and nut. Now that we have that one loose, we can go ahead and follow the factory wiring here around the battery, hold it in place with some zip ties, measure it out to our terminal we'll be using, trim it back, and add our larger ring terminal. Once we make all of our connections, we'll be able to hook up our power wire. Now, while we're over here with our breakers, we're going to go ahead and make our wire connection that goes from the copper terminal for our brake controller over to the battery also, so we can get that out of the way. Now since we don't have enough extra duplex cable to run from our brake controller back outside to the engine compartment, we're going to bring in about a 10-foot piece of it, which we do carry on our website. That part number is 10-2-1. That's the Deka jacketed 2-wire 10-gauge brake wire. Now that we have our extra piece of duplex cable, we're going to go ahead and strip this back again like we did the first piece that way we can make our ground wire for our brake controller and our jumper wire from our breaker to our battery. Now that we have our duplex jacket stripped back, we're going to go ahead and take the piece that we stripped back and expose the 2 wires, and we're going to go ahead and cut the black wire here back to where we stopped stripping it back. We'll go ahead and snip our black wire, set our duplex cable aside, and we'll strip both ends of this black wire, put a small ring on one end and a large on on the other. The smaller ring terminal will go our breaker, and the large one will get ran towards the battery. We'll go ahead and take our small ring terminal we just attached, attach it here to our 20-amp breaker on the copper side and then run our larger ring terminal over with the other one towards the battery. Now, we're taking our larger ring terminal, run it like we did our other one towards the battery, and then we can go ahead and zip tie those wires off once we make our connections here to our positive side of our battery. Now, we'll go ahead and take our extra length of duplex cable that we just trimmed off the excess and run that over towards the driver side of our vehicle. The black wire will be the power wire from our brake controller. We'll go ahead and strip that back, put a small ring terminal on it, and it will go here on the silver post, and our white wire will be our ground. We'll just keep it here in the sheathing with the black wire run enough around and eventually connect it to the negative post on our battery. Now that all of these connections are made, we'll go ahead and snug down the nuts for each one of them just to hold our wires up where we want them to be. Now that we have all those connections made, we'll go ahead and run our white wire around towards our battery and install a larger ring terminal on it once we get it trimmed to length, and that will be the ground for our brake controller. Then after that, we'll go ahead and take some zip ties and clean up our wiring here over on our firewall. Now, we'll go ahead and take our white wire that's connected to the blue wire at the rear of the vehicle and then our duplex cable that has our power and ground wire from our battery and run it into our vehicle. There's a big grommet that has a bunch of wires ran through it right here on the firewall. You can go ahead and pull that grommet out a little bit and allow you to get room to push this in next to it. If you put a little slit in the grommet, it will allow you to run it right next to it, and then, you can go ahead and take some silicone to seal it up. Then, you can inside, grab the wires, and pull them down. I'm going to go ahead and go back into the engine compartment and check to make sure we have all of our wire pulled in and then put our grommet back in place after we've trimmed it a little bit and then put some RVT Lock-Tite silicone on there to seal up the slice just to seal up any gap that we could have created by putting our wires in. Now, we're ready to bring our Voyager brake controller into our install. Normally, your brake controller would be mounted here, on the dash, or on the inside of the dash here on the kick panel. For this application, since the driver has extremely long legs, he doesn't want to kick it every time he gets into his truck, we're going to go ahead and mount it here on the dash and run our wires down here through this panel. If you grab this panel and remove it, you can see there's plenty of room here. We may have to trim just a little bit here at the top to get our wires ran through, but we will be able to run our wires right there. We'll put some loom on this to clean up our install look, but for this application and since we're running our wires like that, we're going to go ahead and cut this connector off and hard-wire our brake controller into our wiring system. We'll go ahead and do that now. To make our connections a little bit easier, I'm going to trim each one of them a little shorter than the next, that way our butt connectors will be staggered so we can get them as tight as possible when we do our bundle. We have our wires stripped back here. We're going to sit this aside for right now, and then, we're going to go to our brake pedal. We need to find the wire that gets power when the brake pedal is pressed. Now, we'll go ahead here to our brake switch, which is right here and connects to our brake pedal. Go to the top one. As you can see, the brake pedal is not pushed but it's getting constant power, so it's not that one. We'll go to the next one. It's a purple with a red stripe. Pull on the brake pedal and you see when the brake pedal is pressed that light comes on. That will be the wire we need to tap into. Again, that's the purple wire with the red stripe. We'll go ahead and trim back the plastic covering here just so we have a little more access and it's easier to make our connection with our quick-splice connector that comes with the ETBC7 kit. We'll go ahead and put our quick-splice connector end to it. We'll just get an extra piece of red wire that we have laying around, feed that into it, and crimp down our connection. Now, we'll just take a piece of red wire and run it into that connection. We'll go ahead and close that up, and now, we can take our 4 wires that we have ran and run them up here into the dash and out the opening on the side. We can start making our connections to our brake controller. Our of this opening, take our red wire we just ran and run it up with these. I'll go ahead and add butt connectors to each one of our wires on our brake controller. We'll go ahead and sit that aside for a second and trim our wires that we need to length. We want to go ahead and just leave a little extra as we have plenty of room to tuck the wire in right here and zip tie it up out of the way. You don't want to cut yourself short and then have not enough wire to run your brake controller up to your dash. We'll go ahead and just measure it out. We'll have plenty if we trim our wires at this length. We'll go ahead and strip back our wires, and we can start connecting them to our brake controller. Now, our blue wire coming from our brake controller will go into the single white wire that we ran from the back from 7-way blue wire up into our engine compartment, in underneath the dash, and to our dash. That will be the signal from the brake controller to our trailer. Next up will be the black wire coming from the duplex cable, and that will be the power wire for our brake controller. The next will be our second white wire coming from our duplex cable, which will be the ground for our brake controller. Our final wire will be the red wire coming from our brake light switch, which will signal the brake controller when we hit our brakes. Now that we have all of those connections made, I'll go ahead and wrap them up with some electrical tape just to clean up our install look and to bundle them up. We are also going to put a little slit here in the cover just so the wires can run nicely next to it so you can shut your door. We'll put a couple pieces of tape around, and that will hold it into position. Now, we'll go ahead and bring our bracket in, mount it to the dash, and then get our brake controller mounted. We'll go ahead and get a pilot hole started and that will make it a little easier because this is on a weird angle. Now, we'll go ahead and set our brake controller into our bracket and install the screws through the bracket and through the side of the brake controller. We'll go ahead and tighten our 2 screws here to hold our brake controller in place. Now, we'll take our trim piece and I'm just going to go ahead and trim the section right here with a pair of snips. I'll go ahead and score it here with a utility knife. We'll go ahead and hook up our ground wire for our brake controller first here on the negative post of the battery. Now that we have our ground hooked up to the negative side of our battery, we'll go ahead and come here to the positive post, bring in our 2 power wires, install those, bring our cover over, and cover up our terminals. We can go ahead and hook our trailer up and test our brake controller. Now with our brake controller hooked up and tested, that will do it for our install of the Takonsha Voyager Brake Controller, part number 39510, along with part number ETBC7 on our 2014 Ford F150. .

Ratings & Reviews

4.8

750 reviews

See what our Experts say about this Tekonsha Trailer Brake Controller

- Most Economical Trailer Hitch Receiver and Wiring Harness For a 2023 Honda Pilot TouringOur etrailer Trailer Hitch Receiver # e27KR you found is our most economical custom fit receiver for your 2023 Honda Pilot Touring edition. For the wiring you can select from either the 4-Way # C48ZV or the 7-Way # C35ZV depending on the types of trailers you will be towing. If you have a trailer with a 7-way you are also most likely going to need a Trailer Brake Controller # 39510 along with the Wiring # 20127 to connect it. This is one of our most economical and reliable proportional...

view full answer... - Should Blue Wire From Brake Controller Have Constant PowerThe blue wire coming from the back of your Tekonsha Voyager Brake Controller # 39510 is for brake output to the 7-Way connector. This wire should only have power with the brake pedal depressed or the manual override activated on the brake controller. If you are getting constant power on this blue wire this may be an indication that the controller is bad but there is an easy way to test this. You will want to first sever the blue wire several inches from the back of the controller. Then...

view full answer... - Is Reese Voyager and Tekonsha Voyager the Same Brake ControllerThey are the same controller as Reese and Tekonsha are made by the same company. The Tekonsha part # 39510 does not come with the vehicle specific install harness part # 3035-P which is custom fit for your 2003 Ford F-250/350.

view full answer... - Tekonsha Voyager Brake Controller Not Activating Trailer Brakes When Brake Pedal Is PressedYes, we can help you test your brake controller and determine if the controller is bad or if there is a wiring issue that is causing the problem on your 2003 Ford F-250 pickup. Lets start with the easiest things first. Be sure that when you are testing the trailer brakes with the brake pedal that the vehicle is moving. The trailer brakes will not apply with the brake pedal if the vehicle is not moving because of the proportional sensor. The first thing I would check is the red wire that...

view full answer... - Troubleshooting No Green Light on Tekonsha Voyager Brake ControllerThe green light on top of your Tekonsha Voyager Trailer Brake Controller # 39510 indicates that a trailer is connected to your vehicle. If this light is not turning on when connected to a trailer there are a couple things, you can check. I first recommend inspecting both the vehicle side and trailer side connectors for any debris or corrosion built-up around the pins that needs to be cleaned out. If the connectors look good, you will next want to test the brake output pin on the vehicle...

view full answer... - Trailer Brakes Do Not Activate With Brake Pedal When Trailer is Sitting StillActually that is a possibility. Proportional brake controllers will not engage the brakes with the pedal unless the tow vehicle is in motion. Another possibility is the red wire from the brake controller isn't connected correctly. It needs to be connected to the cold side of the stop light switch or the wire that is hot only when the brake pedal is pressed. I would also check any fuses related to towing and replace if necessary. If none of these ideas solves your problem let me know...

view full answer... - Which Harness to Install Tekonsha Voyager in 2019 Ram 1500 ClassicWhat brand and model is the brake controller? The Rams changed quite a bit in 2015 so a new harness would be needed. But if you can get me the controller you have I can help pick you out what you'd need.

view full answer... - Fuse Location to Power an Electric Trailer Brake Controller on a 2005 Chevy SilveradoThe Tekonsha Voyager Brake Controller with GM Wiring Harness, # 39510 and # 3015-P, itself does not have a fuse. Since it is connected to the truck via the factory port under the dash, the fuse for the brake controller 12 volt power is located in the power distribution box under the hood. We actually have an FAQ article that explains the installation of a brake controller Chevy and GMC trucks that includes your 2005 Silverado. It covers the connections that need to be made under the hood...

view full answer... - Voyager Brake Controller Red Light Not Coming On with Brakes Applied on a 2004 Chevy SilveradoThere are several possible causes that would lead the red light not to come on when applying the brakes or manual override on the Tekonsha Voyager Brake Controller, # 39510. First, if truck is not moving, the brakes will not activate. You will also want to check to make sure the power setting is not too low. There may be no signal from the brake light switch. You will need to test the red wire from the back of the brake controller using a circuit tester like # PTW2993. If there is no voltage,...

view full answer... - Troubleshooting a Tekonsha Voyager Brake ControllerHey Scott! You're going to need to connect a trailer to your vehicle. You're not going to know what's working correctly or incorrectly on the Tekonsha Voyager item # TK29ER unless you hook a trailer up. If you run into any problems down the road feel free to comment below or email me directly and I'll be happy to walk through them with you.

view full answer... - Recommended Wiring for 1998 Ford F-150 to Add 7-Way to Factory 4-Way Trailer ConnectionFor your 1998 Ford F-150 Extended Cab with factory 4-way flat, you need the Tekonsha Ford Replacement OEM Tow Package Wiring Harness, 7-Way # 118242. This will give you the two additional relays needed as well as the wiring harness. Then you will need a brake controller. I recommend the Tekonsha Prodigy P3 # 90195 as well as the wiring adapter # 3035-P. This will give you an easy to use proportional brake controller with easy to use presets as well as a nice LCD screen for diagnostics....

view full answer... - What Are the Brake Controller Wire Colors for on a 1998 Dodge Ram 2500The factory electric trailer brake controller wires on a 1998 Dodge Ram 2500 are as follows: Power - Red/Orange Ground - Black/Orange Stop Light - White/Tan Brake Output - Light Blue For a brake controller, I recommend using the Tekonsha Voyager Trailer Brake Controller part # 39510. It sounds like the previous owner of your truck may have cut off the old brake controller port so you are also going to want to use the Replacement Brake Control Plug-In Harness for Tekonsha and Draw-Tite...

view full answer... - Troubleshooting Vehicle that Won't Start After Brake Controller InstallWithout knowing what truck you have it's hard for me to know if you have the correct harness. I will say that the problems you are describing are unlike any problems we have ever seen from installing a brake controller. If removing the brake controller makes the problems go away then I would strongly recommend you do so until you figure out why this problem is occurring. Make sure you have your truck shifted into park or neutral before you attempt to start it. You may have moved the shifter...

view full answer... - Where is the Brake Controller Plug In Located on a 2011 Ford F-250 Super DutyOn the 2011 Ford F-250 Super Duty, the brake controller port is located behind the center dashboard access panel on the passenger's side. One end of the # 3034-P adapter will plug into the back of the brake controller and the other end plugs into the brake controller port on your vehicle. If your vehicle has the factory 7-Way connector on the rear of your vehicle, then all of the wires for the brake controller have already been run. If you have a factory 4-Way connector on your vehicle...

view full answer... - Troubleshooting Voyager Trailer Brake Controller Not Working when Brake Pedal is PressedIt is possible that either the connection to the brake switch is no longer good enough to provide an adequate signal to the brake controller and a new connection will need to be made, or there is a short or possibly a bad ground causing the problem. You may want to also check the stoplight fuse. A blown fuse will not allow the signal to get through and the brake controller will not know you are stepping on the brakes. You can find the fuse by checking your owners manual which should have...

view full answer... - Troubleshooting LED Indicator Light on Tekonsha Voyager Brake Controller 39510The green light on the Voyager brake controller # 39510 should come on as soon as you plug the trailer into the vehicle. If it does not come on at all, this indicates that you either have some corrosion inside the trailer or vehicle plugs that is causing a short, or you have a loose power or ground connection. Check the plugs on both sides of the setup for any white or green corrosion. If you see any, clean the plug thoroughly or just replace it. If you don't see any buildup in either...

view full answer... - Recommended Brake Controller for a 2018 Thor Ace MotorhomeFor your 2018 Thor Ace Motorhome, I recommend using the Curt Spectrum Trailer Brake Controller part # C51170. The reason for this is because this unit is composed of two main parts, the control box and the output knob. The control box gets mounted out of site and then the output knob will get installed up on your dash for easy use and a very aesthetically pleasing look. The color output of the knob also helps with ease of use. Since your motorhome is on a Ford F-53 chassis, you can use...

view full answer... - How to Find the Brake Wire on a 2001 Toyota Tacoma for Brake Controller InstallWhen we installed a brake controller in a very similar Toyota Tacoma as your (see attached install video), we found that the correct wire to use for the stoplight switch was dark green wire with a white stripe. You should still test this wire for voltage with the circuit tester to verify it is the correct one. But this would be an excellent starting point.

view full answer... - Casita Travel Trailer With Repeated Issues On Left Side Of Axle OnlyHello Paul. It sounds like you have an axle, or axle mounts that are out of alignment. That is really the only explanation since the issue has been reoccurring even after several replacements. I wonder if the 1st axle sustained damage of some sort which bent the mounts. This would explain the bearings overheating also. At this point I suggest you take your camper to a shop and have them check the alignment of the axles and the mounts.

view full answer... - Troubleshooting A Tekonsha Voyager Brake Controller That Isn't Sensing The TrailerHi Howard, Typically if the Tekonsha Voyager Trailer Brake Controller # 39510 isn't detecting the trailer it's just an issue with the trailer connectors not making a solid connection. Check the pins on your trailer connector to see if they're corroded, damaged, bent, or dirty. A lot of the time the pins get bent back from connecting to the 7-way socket on the vehicle over and over and just need to be bent back into place with a thin flathead screwdriver so that they contact the pins in...

view full answer... - What To Do if an RV Dealership Installs a Brake Controller Incorrectly and Damages Cruise ControlIt sounds like the RV dealership that installed your Tekonsha Voyager Brake Controller part # 39510 did not install the controller correctly initially, and even though he attempted to rewire the controller the damage was done to your vehicle and now you have lost cruise control. I would recommend having the mechanic look at the circuits like you are doing, and then once they confirm that the initial install of the controller screwed up your cruise control circuit I would go back to the...

view full answer... - Correct Brake Controller Adapter for 2011 Ford F-150If you have one of the following brake controllers, we offer a complete plug-in application. No wiring needed, just plug one end of the Tow Ready Plug-In Wiring Adapter, # 22292, into your brake controller and the other end will plug into the built-in harness beneath the dash on your 2011 Ford F-150. Brake EVN # TK63VR Tekonsha PowerTrac # 39523 Tekonsha P2 # 90885 Tekonsha P3 # 90195 Tekonsha Primus IQ # TK90160 Tekonsha Voyager # 39510 If you have a different brand of brake controller,...

view full answer... - Stop Light Switch Wire for Installing a Brake Controller on a 2013 Audi Q5According to my research the wire that carries the cold side of the stop light switch on your 2013 Audi Q5 should either be Red, Red/Gray, or Red/Black. You will need to test this with a circuit tester like part # PTW2992 and then connect the red wire from the pigtail # 20127 for the Voyager # 39510.

view full answer... - Trailer Brake Controller No Longer Works with Brake Pedal on a 2008 Chevy SilveradoThis sounds like a problem on the red wire. The red wire is the input wire from the brake switch that tells the controller when you are stepping on the brake pedal. Use a circuit tester like # PTW2993 if needed to test the wire. If there is no signal when you step on the pedal, then you know this is the culprit. There are a couple of things you can check but since it was working before the most likely problem is a blown stop light or CHMSL fuse. Use the vehicle owner's manual to find...

view full answer... - Which Brake Controller Install Harness Fits 2022 Ford E-450 CutawayFor your 2022 Ford E-450 cutaway chassis the correct Tekonsha brake controller install harness is actually the part # 22292. This is why what you have doesn't look like it would work with the 3035-P.

view full answer... - Parts Needed To Add Hopkins 7/4 Pole Connector To a 2020 Ford F-150 With Factory 4-WayI have a couple ways you can install the 7- and 4-Pole Trailer Connector Socket # HM40975 on your 2020 Ford F-150 with a 4-way flat factory connector. The first is going to be the easiest but is more costly. You will use the harness from the Curt 7-Way # C56413 and connect to the connector you found. The Curt harness will connect to the factory wiring as seen in the installation video I have linked near the bottom of the page. Otherwise we do have the Hard Wire Connector # 20147 which...

view full answer... - Parts Needed To Install a Redarc Tow-Pro Liberty Brake Controller On a 2020 Ford F-150 XLTYes, you can install the Redarc Tow-Pro Liberty Brake Controller # RED24FR on your 2020 Ford F-150 XLT. You will need the Tekonsha Plug-In Wiring Adapter # 22292 to connect to the factory connector on your F-150 that came with a 7-way towing connector. Then you will connect the Liberty to the Tekonsha harness using the Adapter # 331-TPH-017. There is a chance that your factory connector will not have battery power on the connector. If your connector does not have power you will need the...

view full answer... - 7-Way and Brake Controller Solution for 2018 Ford F-150 without Tow PackageYour 2018 Ford F-150 without the tow package and 7-way does have brake controller wiring currently so once you have the 7-way part # C56413 installed you'd be able to easily install a brake controller using the truck's factory wiring. The P3 part # 90195 and the install harness part # 22292 would be a really great and easy to install option. This is the most advanced and easiest to use brake controller on the market so I recommend it highly.

view full answer... - Does Computer have to be Flashed to Install Aftermarket Brake Controller on a 2016 Ford F-150We have installed brake controllers on 2016 Ford F-150s, see video link, and have not had any problems regarding having to flash the computer for it to work. For a brake controller I recommend the P3, # 90195 with wiring harness # 22292. The P3 offers easy to understand diagnostics, presets you can program if you tow different trailers, and a host of other options making it the most versatile brake controller available.

view full answer... - Locating Factory Brake Controller Plug on 2015 Ford F-150There should be a factory brake controller plug on your 2015 Ford F-150, whether it came with a 4-Way or 7-Way connector at the back of the truck. The plug will be located beneath the dash inside your cab. You may need to remove some shroud around the steering wheel compartment to access the plug. I have attached an installation video on the 2016 Ford F-150 that you can take a look at. The process should be very similar for your 2015 model. The correct plug-in adapter for your Ford F-150...

view full answer... - How Does Brake Controller Install on 2019 Ford F-150 with Factory 4-WayTo install a brake controller like the Hopkins Agility part # HM47295 in your 2019 Ford F-150 you'd actually just need the # 37185 which would plug into the 4-way you have at the rear of your truck and then you'd splice the blue wire of the adapter to the blue wire of the harness you can see in the attached picture. Instead of the Agility I would strongly recommend the iCommand part # TK63VR as it performs much better and is much more reliable as well. For a Class III hitch part # C86HR...

view full answer... - Where To Find The Factory Brake Controller Wire Harness In A 2023 Ford F-150 Hey Phil, If you're looking for the factory wire harness for a plug and play connection you'll find a connector that's gray with a red/orange center like the plug on the Curt Custom Wiring Adapter for Trailer Brake Controllers # C51436. This connector is hidden in the dash behind the center console under the driver's side vent. If you look up a Ford factory brake controller install it will show you the way to access this harness. I've seen it done before and it's quite a bit of trim and...

view full answer... - Where Does a Trailer Brake Controller Plug In on a 2013 Ford F-150The plug on a 2013 Ford F-150 to plug in a brake controller wiring harness is hidden pretty well. You actually have to temporarily remove a panel from the center console to access it. Wiring harness # 22292 is the correct wiring harness for you truck. I have indued a link to a video showing a typical installation that will help you locate the factory plug.

view full answer... - Location of Brake Controller Connector on 2013 Ford F150The connector for installing a brake controller is located under the dash, just to the right of the diagnostic port, which is right above where the driver's right knee would be. If you don't already have the vehicle specific plug for the 2013 Ford F150, you'll need part # 22292. One end would plug into the back of the brake controller, the other would plug into the connector under the dash. I've linked you to an install video showing the Prodigy P2 brake controller being installed on a...

view full answer... - Does Ford Dealer have to Activate Aftermarket Brake Controller on a 2015 Ford F-150You will not have to have a Ford dealer activate the brake controller on your 2015 Ford F-150. You just need the proper wiring harness to plug the P3 # 90195 into your truck. The proper harness is # 22292. If you also need the mounting bracket for the P3 it is # TK5906.

view full answer... - Parts Needed to install Brake Controller in 2017 Ford ExpeditionHey Dave, your 2017 Ford Expedition would have came with a factory 7-way trailer wiring harness so to update your wiring so that you can install a brake controller all you need is the correct harness that plugs into the port under your dash like the # 22292 so you can install a controller like the P3 part # 90195 and you'd be set.

view full answer... - Correct Brake Controller Adapter for 2011 Ford F-150If you have one of the following brake controllers, we offer a complete plug-in application. No wiring needed, just plug one end of the Tow Ready Plug-In Wiring Adapter, # 22292, into your brake controller and the other end will plug into the built-in harness beneath the dash on your 2011 Ford F-150. Brake EVN # TK63VR Tekonsha PowerTrac # 39523 Tekonsha P2 # 90885 Tekonsha P3 # 90195 Tekonsha Primus IQ # TK90160 Tekonsha Voyager # 39510 If you have a different brand of brake controller,...

view full answer... - Best Brake Controller For Multiple Different VehiclesHi Terry! Just to make sure, are you wanting one brake controller that will work with all 3 vehicles, or a separate brake controller for each vehicle? I have both options listed below, but curious. One Controller For All Three Vehicles (one to rule them all, per se): Tekonsha Prodigy P3 Trailer Brake Controller - 1 to 4 Axles - Proportional # 90195 Wiring Needed For Each Vehicle: 2016 Jeep Wrangler: Universal Installation Kit for Trailer Brake Controller # ETBC7 2020 Jeep Cherokee: Tekonsha...

view full answer... - What Vehicle Specific Pigtail do I Need for My Tekonsha P3 for My 2001 Ford F-350, Mounting Bracket?Hello Kip, Nice choice on brake controller, definitely my go to! For your 2001 Ford F-350 you will want the Tekonsha Plug-In Wiring Adapter for Electric Brake Controllers - Ford, Lincoln, Mercury # 3035-P. For the bracket it comes in 2 pieces, the part that attaches the brake controller # 2178, and for the bracket that mounts to the vehicle # TK5906. Getting a second truck all set-up for easy swapping?

view full answer... - Recommended Trailer Brake Controller For a 2022 Ford F-150 With Factory Tow PackageI recommend the Tekonsha Prodigy P3 Trailer Brake Controller for your 2022 Ford F-150. This brake controller is proportional so once you have it adjusted to your trailer it will automatically adjust braking output for light and severe braking situations. This will help keep you from worrying about reaching down to adjust the trailer brake pressure is those situations. The LCD screen is customizable and the built in diagnostics help you to troubleshoot any issues that might occur with the...

view full answer... - Installing the RoadMaster Transmitter # RM-9420 for Even Brake on a 2017 Ford F-150If you use a circuit tester like part # PTW2993 you should be able to locate some wires behind or around your brake pedal and test them. If one gets hot only when your brake pedal is pressed, then you can connect the RoadMaster Transmitter # RM-9420 to that. Otherwise, your best bet would be to locate the trailer brake controller connector and tap into the stop light switch that way. If you check up under your dash to the right of the steering wheel (basically behind that center panel)...

view full answer... - Adding a 7-Way Connector and Brake Controller to a 2018 Ford F-150 with Factory 4-WayI will be happy to get your 2018 Ford F-150 set up with a 7-Way trailer connector and a brake controller. The method for doing so that requires the fewest parts is to hardwire in the brake controller/7-Way. Since your truck already has a factory 4-Way connector you will just need # ETBC7 to add a 7-Way, retain the 4-Way, and have the parts needed to install a brake controller as well as run a 12 volt hot lead. If you do not already have a brake controller picked out I recommend the P2...

view full answer... - How to Add Brake Controller and 7-way to 2020 Ford F150 w/ Factory 4 pole Trailer ConnectorTo add a 7-way, you can use part # 118283, and plug it inline at the connection between your existing 4 pole and the factory wiring harness. To install the Tekonsha P3 # 90195 brake controller, all you'll need is the # 22292 wiring adapter to connect the brake controller and the connector behind the dash as shown beginning at the 4:35 mark in the brake controller installation video I've linked for you.

view full answer... - Installing a Brake Controller in a 2016 Ford F-150 with Factory 4-Way Flat ConnectorFor your 2016 Ford F-150, the Tekonsha Prodigy P2 # 90885 is a great option. To install this, you will need the wiring harness # 22292. This adapter plugs into the built-in connector beneath your vehicle's dashboard. To access this connector, first locate the instrument cluster finish panel in the center of you dash, near the driver's side. Carefully pry the panel out and undo the locking tabs to remove the panel. Plug the adaptor into the mating connector in the large gray housing behind...

view full answer... - Installing Aftermarket Brake Controller on a 2018 Ford F-150 Without Pins for Brake Controller FuseSince you don't have the pins in the fuse position 24 that means you will need to use the Kit # 5506 to install the Prodigy P3 # 90195 with the Adapter # 22292 on your 2018 Ford F-150. For some reason Ford doesn't always have that 24 location pinned for a brake controller so there are a few extra steps that you need to take to power your brake controller. These are actually highlighted in the attached installation video starting at about the 8:40 mark.

view full answer... - Troubleshooting 2017 Ford F-450 Integrated Brake Controller that Only Works with Override LeverThe controller should be proportional in your 2017 Ford truck which means that you'd have to be moving to have the brakes on the trailer lock up with the truck. Is there any type of output visible on the brake controller when you apply the brakes?

view full answer... - 2015 Lincoln Navigator Brake Controller Wiring Harness Connection LocationIt seems like you may have the incorrect wiring connector and the harness in the photo is not the correct fit. For your 2015 Lincoln Navigator, the correct wiring adapter is # 22292 for your Tekonsha Prodigy P3 # 90195. If you have the factory 7-way or factory 4-way, this harness will work. The connector will be located in the center of the dash on the driver's side behind a trim panel. I've attached the installation details to assist as well as some videos to help. The wiring harness...

view full answer... - Installing a Brake Controller on a 2012 Ford F-150 with a Factory 4-Way Trailer ConnectorSince your 2012 Ford F-150 did not come with the factory to package, the blue wire for the electric brake output can be located at the manufacturers connector in the engine compartment on the drivers side near the firewall. You will notice a dark blue wire going into the connector, but not coming out. I have attached an installation video showing where this wire is located. I recommend watching the entire installation video because it explains how to install a 7-way trailer connector,...

view full answer...

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.