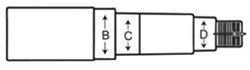

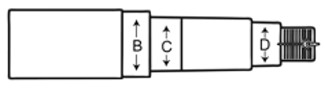

Seal contact surface (B)

Inner bearing (C)

Outer bearing (D)

Axle capacity

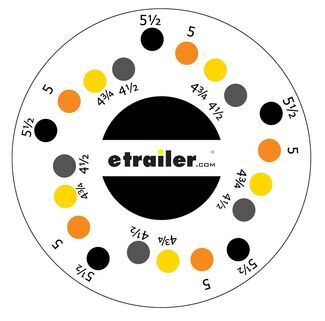

Wheel bolt pattern

Hydraulic surge brake actuator

Number of axles

Direct Mount to Spindle

1-3/4" Diameter

2-3/8" Diameter

3" Diameter

3" Diameter

Mount over Idler Hub

2-3/8" Diameter

3" Diameter

3" Diameter

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

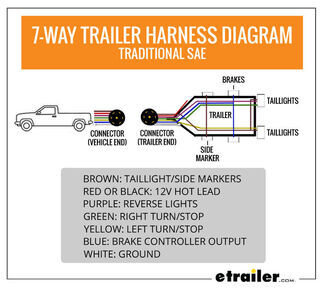

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"Very helpful/friendly Customer Service. Competitive Pricing. Shipping was Fast."

John

Mankato, MN