Tekonsha Prodigy P3 Trailer Brake Controller w/ Custom Harness - Up to 4 Axles - Proportional

with factory Tow Package

without factory Tow Package

Will this fit?

To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

- All Info

- Reviews (6614)

- Q & A (0)

- Videos (10)

- Photos

Tekonsha Trailer Brake Controller

- Electric

- Electric over Hydraulic

- Proportional Controller

- Up to 4 Axles

- Tekonsha

- Under-Dash

- Plug-In

- Under-Dash Box

- Multiple Trailers

- LCD Display

The Tekonsha P3 is a brake controller beloved for its reliability and useability. You're able to save your settings and multiple profiles. It's easy to install, and with the custom harness, it's plug-and-play.

Features:

- Proportional - Smooth, safe, and good for your brakes long-term

- Great for a fleet - Save and customize multiple profiles

- Installs quickly - Mount the bracket to the dash, then attach the unit to the bracket

- Plug-and-play - Custom harness included

- Simple controls - Large, accessible buttons for all your settings

- Easy-to-read display includes diagnostics - Straight-forward messages get you to the root of the problem quickly

- Safe - Built-in safeguards protect vehicle, trailer, and controller

- Quick disconnect - Easy to unplug and remove the controller when you don't need it

- Automatic leveling - Must be parallel with direction of travel and horizontally level

Specs:

- Application: trailers with up to 4 axles (8 brake assemblies)

- Compatible with electric or electric-over-hydraulic trailer brakes

- Overall dimensions: 5" long x 3-1/2" wide x 1-3/8" tall

- LCD display dimensions: 1-3/16" wide x 9/16" tall

- Mounting range: 360 degrees vertically

- Warranty:

- Limited lifetime on brake controller

- Limited 1-year on wiring harness

Braking Output

Braking output is the maximum amount of power that will be applied to your trailer's brakes. How much braking output you need is determined by the weight of your trailer; a heavier trailer will need more power to bring it to a stop. You want to go as high as you can without the trailer brakes locking up.

Use the arrow buttons on the front of the module to set the output.

Power Boost for Heavy-Duty Towing

The boost setting controls the aggressiveness of your trailer's braking, meaning how quickly the brakes reach the maximum braking level. If your vehicle takes too long to come to a stop, increase the setting. If it stops too abruptly, decrease the setting.

Depending on the level of boost, your trailer brakes can start at either 13 percent or 25 percent of the set braking output. So instead of starting at 0, the brakes will start at 25 percent and get to 100 percent sooner. This keeps the trailer from pushing your tow vehicle forward.

Boost Levels:

| Approximate Gross Trailer Weight | Boost Level | Increase in Initial Power Output |

|---|---|---|

| Less than tow vehicle GVW | B1 | 13% |

| Equal to tow vehicle GVW | B1 or B2 | 13% or 25% |

| Up to 25% more than tow vehicle GVW | B2 or B3* | 25% |

| Up to 40% more than tow vehicle GVW | B3* | 25% |

*Both B2 and B3 offer a 25-percent boost in initial power. But the braking curve for B3 is more aggressive than that of B2. This means that, even though you will start out with the same intensity when using these boost levels, you will get an overall more aggressive braking experience with the higher level. So if you use B3, you will reach maximum braking sooner than if you use B2.

Manual Override

To engage the manual override, twist the rotary-style lever from right to left. This will activate the trailer's brakes and brake lights independently of your vehicle, great for stopping sway or controlling your trailer's momentum in an emergency.

Save Your Settings in Multiple Profiles

The P3 is able to store your settings in multiple profiles so that you can have them ready to go for different trailers and drivers. Even the display is super customizable: you can change the screen color, brightness, and language to make it easy to use.

Troubleshoot with Detailed Diagnostics

The P3 makes it easy to troubleshoot problems as they come up, with comprehensible and detailed diagnostics displayed on the screen.

Diagnostic troubleshooting messages include:

- Battery voltage

- Voltage supplied by stop light switch when brake pedal is depressed

- Output voltage to trailer brakes

- Output current to trailer brakes

Diagnostic warning signs include:

- Open ground

- Overload

- Output short

- Power loss

- No trailer connection

Safety Features

The Prodigy P3 offers advanced safety features to prevent damage to various components of your towing setup.

-Integrated reverse battery protection shields the brake controller and your trailer's breakaway system from shorts.

-When the P3 is not in use, it draws only 3.6 milliamps, minimizing drain on your vehicle's battery.

-Any time your vehicle and trailer are at a standstill with the brakes applied for more than 5 seconds, the hold feature will kick on and reduce power to just 25 percent. This will keep your trailer in place without your brakes overheating.

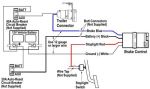

Installing the Tekonsha P3

Installing the P3 is incredibly simple. You'll mount the bracket to your dashboard then mount the unit to the bracket. Plug the custom harness into your vehicle and into the unit. Done!

Keep in mind that the P3 must be horizontally level and parallel with the direction of travel to work correctly.

With a replacement wiring harness (sold separately) and replacement bracket (TK5906 - sold separately), you can even transfer the Prodigy P3 to another vehicle.

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake controller installation kit (ETBC7 - sold separately).

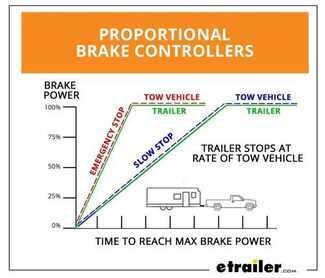

What is Proportional Braking?

Proportional braking means that your trailer brakes mimic your tow vehicle's brakes. If you slam on the brakes, your trailer brakes will activate with the same intensity; if you brake lightly, your trailer brakes lightly too. The trailer's braking is in proportion to your vehicle and trailer.

The Prodigy P3 uses an internal inertia sensor to detect how your vehicle is braking so it can send the right amount of braking power to your trailer. It measures the inertia of your tow vehicle and activates the trailer's brakes to slow at the same rate. The result is uniform braking across your towing setup. No push-pull action - just smooth, proportional braking every time.

90195 Tekonsha Prodigy P-3 Proportional Trailer Brake Control

Replaces 39526 Hidden Hitch and 20195 Draw-Tite Intella-Stop Xtreme Proportional Brake Control

305000 Tekonsha Brake Control Wiring Adapter with 2 Plugs

Replaces 3050-P

Installation Details

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Setting up the Tekonsha Prodigy P3 Trailer Brake Controller on your 2010 Nissan Frontier

Today on this 2010 Nissan Frontier, we're going to review and install the Tekonsha Prodigy P3 Trailer Brake Controller, part number 90195. To help us with our install on our brake controller we'll be using part number 5506. All right, this is what the P3 braking controller looks like once installed in our Nissan. We have 3 settings here that correspond to what size trailer, or how much weight you're pulling behind the truck. P1 for a small conventional truck and trailer. We hit this button here, go to boost level 2. You can see how that icon kind of changes to like a little fifth wheel.

Boost level 3 and it turns to a really big fifth wheeler gooseneck trailer. Then actually, one more time you turn the boost off and you get a typical small truck or a small trailer. With the boost setting on the brakes come on a little bit before the truck brakes come on, and it gives you the feeling of the trailer brakes are working first. It works for a very short time and then it works back to it's inertia activation, so when you lock the brakes, the brake controller locks the brakes at the same time. We also have an up and down arrow, to help set our power. The initial setup, it's a good idea to set it at about 6 or 7, and then adjust it from there, to whatever your trailer requires.

At anytime, if you need to activate the trailer brakes by themselves, all you have to do is move this manual override right here. Move it over to full power right here. Next, we will go ahead and show you how we install this brake controller. We'll go ahead and start with our part number 5506 first, our wiring kit. We will work with this and then work up to our brake controller. Let's go ahead and cover the parts that come with that.

We got 25 foot of cable right here, which is 10 gauge material with 2 wires inside a sheath. We got a variety of ring terminals here to connect with your battery and also a brake terminal to connect up to the circuit breakers. Now the circuit breakers you have will be 20, 30, and 40 amp. Pretty much in every situation you're going to use this kit on, your only going to use 2 and 3. It depends on which amp circuit breaker you need for your particular brake controller. It also includes 4 butt connectors to help hook up your wires. Now to give you an idea of what we're working with on our truck, our truck already has a 7 volt connector wired up to it for just lights alone, so we have our direct wire coming out from here, so we can hook up the rest of our wire harness too.

Now this one has a blue wire and a black wire. The blue wire is going to be used for output for the brake controller and our black wire we use for our 12 volt power supply going out to our trailer. Now on this connector, it makes everything pretty easy to connect to and convenient, however if you have a different style connector, the same principle applies, still look for blue for your trailer brake output and black for your 12 volt power supply. We'll go ahead and remove the sheath on our 2 wires here to get access to our wires here. One note, of course this is not going to be exact color match, we're still going to run ours black to black and then white to blue. Let's go ahead and strip back our wires and get them ready to install. Now let's get our other wires ready. Now the butt connectors, the insides been sitting out and corroded up a little bit, we'll go ahead and use the new butt connectors that come with the kit. Now I'm going to use some electrical tape to help protect our connections here. Now we'll go ahead and run our gray cable to the front of the vehicle. Just make sure you stay away from anything moving like the convention components, or anything hot like the exhaust. What we did in this case, is we ran our wire up along side the frame, over the hitch and up and over the top of the frame. It holds it tight to keep it up and out of the way, we went over these components and lines and hoses, just going over the top of it, ran it along down the side of the frame. There is a space between the frame and the gas tank and we just stuck it between there, over the bracket for the gas tank. Again, with all the frames, we tied them where we could. There happens to be a little opening right here, that we we're able to run our cable through, so that held it up for us. Then we ran it up towards the engine compartment. There is a little heat shield right here, that we will be able to sneak our cable through and hide it up and once we pull it from the top, it will take up all our slack and it will be hidden on the inside. None of our parts come with any zip ties like we're using here today, but you can use part number DW05726-25. Our Nissan here is pretty easy to push the wire up from the bottom and up into an opening right here where you can easily reach it. If it's a little bit harder to get to, you could use a pull wire, basically you could use any type material. We used an old piece of airline tubing, but a coat hanger or any piece of material that you can manipulate. Push down here and tie off and pull back up. We'll go ahead and pull up the slack. Make sure it's not interfering with anything on the engine and we'll go ahead and use another zip tie to hold it in place. We are just going to tie it to the vacuum line here and cut off the excess. Next, we'll go ahead and run our wire out to our power supply, which would be our battery. Let's go ahead and see how much length we'll need. We will follow the existing wire harness and hook it to the positive side of our battery. Next, we'll go ahead and find a location to install our circuit breakers. To help us with the installation, we're going to attach them using some self tapping screws. We'll be using part number 01131802. Now when we install our circuit breakers, it's a good idea to be as close to your power supply as possible and in this case we're going to use the sheet metal right here. Now we're always going to use a 40 amp circuit breaker for our 12 volt power supply for our trailer. In this case, our brake controller we're going to use a 30 amp circuit breaker. To install the screws, we're using a 1/4 inch nut driver. We will overlap it to the mounting tabs and use one screw to hold everything together. With our circuit breakers now on, we will have a better idea of where we're going to run our wires to through those and to our battery here. We will go ahead and cut off our excess. Next, we'll take a moment to split the wires apart, but we will go pretty far back on our wires and split them. Let's go ahead and put our white wire off to the side, eventually that will go inside the vehicle. Let's go ahead and work on our black wire. Now our 12 volt wire is going to go through our 40 amp circuit breaker, which is located right here. Pretty simple to install, we'll go ahead and cut the wire in half, strip them back and we'll install a couple of the small ring terminals. Our circuit breakers are actually labeled. This copper one is labeled BAT, the wire goes to the battery. This silver one is labeled AUX, so going to our battery, we'll go ahead and take our black wire and put it into place and let's install our hardware. Another wire going out to eventually our trailer, it will go on top. We can go ahead and snug those down using a 3/8 deep well socket. Now we'll take the other end of our wire and we'll go ahead and get it stripped back. We're going to attach one of the large ring terminals to it. This will eventually connect to the battery in this location right here. I like to leave the connection to the battery one of the last things I do, so I'll just leave this off to the side. Next up is go ahead and use our leftover length of wire and use that to run between our brake controller from the inside and out to our power supply once again. This will provide our ground and our power for the brake controller. However of course, whatever we have leftover is way too short for the job, so we'll have to use some additional wire. This will happen in situations where your battery is located on the passenger side of the vehicle. The extra wire we're going to be using is part number 10-2-1. This is a Deka 2 wire 10 gauge brake wire. Now we got an extra length of wire here, we're going to have about maybe a tenth of a chunk and we're going to combine it with our white wire here, it's separate and we're going to run that through the grommet to the inside of the vehicle. The grommet is going to be located in this corner right here. We will make a slit into that using a utility knife or actually a pocket knife works really good in this application. Just make a slit in there, just enough to where we can run our wires through. Just make sure we stay away from the wires on the side. I'm going to bundle my 3 wires together temporarily with some electrical tape and we'll push on through. I'll go ahead and push it in, chances are it's going to be hidden behind the insulation a little bit, on the inside of the vehicle. We'll go ahead and take our new cable here and follow a path for the original black cable. Then we'll see how much wire we need going through the circuit breakers and to our battery. Also this time, you'll need to accommodate for going to our power supply battery and also our ground, or negative side of the battery. We'll go ahead and cut off our excess one more time. We'll also take a few moments and go ahead and separate our wires, give us some working room. We will separate a small section here and get access to our black wire. Not let's go ahead and cut our black wire in half and we'll connect it up to our 30 amp circuit breaker, just like we did with our other wires. We'll go ahead and take 2 more small ring terminals and add it to our wires. One wire is going to our battery and will go to the copper side and your brake controller will go to the silver side of the circuit breaker. We'll cut our black wire off short, we don't need all that length and add our large ring terminal. We'll also do that to the white wire as well, but we'll leave it at it's original length. Once again, I'm going to leave my connections to the battery as the last thing I do, so let's tuck them out to the side for now. Now we will go ahead and take a moment to zip tie our wires up and bundle them up and keep them safe and secure and out of the way from the engine. I'm going to go ahead and cut them off even and strip back the wires. Now let's get our wires for our brake controller out. This is the wires that do come with the P3 brake controller. We'll go ahead and loosen them up and we'll use the supplied butt connectors that do come with the brake controller. Put the wire back and add our butt connectors. Now the brake controller comes with 2 small butt connectors, which isn't going to be enough for our white one, but our wiring kit does come with an extra butt connector that we can use for that purpose. The easy ones, black to black and white to white. Then our single white wire, we'll connect it to our blue wire. Now we have a single wire remaining, which is our red wire, this will connect up to the inaudible 00:13:04 sided brake switch, so when you hit your brake pedal, that turns on the brake lights and that's the circuit you want, so that will turn on our brake controller when it's needed. Now to tap onto our brakes on our truck, we're going to use a quick splice wire connector. We'll be using part number 564. Now on our Nissan, we're going to tap into the wire right behind one of our brake switches here. Follow our brake pedal up, we found out this yellow wire here is our brake signal, so we press the brake pedal, it gets hot. To use the quick splice connectors is pretty simple, just connect it over the wire that you want to use and then the wire you want to tap into or add to it you slide next to it. We are pretty tight up in there, so give me a moment, I'll have this hooked up and you can see what we did. Now you can see here my quick splice in place and our red wire sitting next to my yellow wire here and the quick splice is doing the job. Now I'll go ahead and find a place for our brake controller. The rules are pretty simple, basically you want to make sure you have it in an easy accessible area so you can manually activate it if you need it in an emergency situation. Make sure it's in a straight line with the vehicle and as little twist left to right as possible. You can install it up or down, you got 360 degrees of rotation to install it. If you want to you can install it this way, vertical and look down on it worked out better for you. In this case, I'm going to say we'll use this location right here, so it's easily accessible. Our mounting bracket consists of 2 pieces. We have this piece right here that gets bolted to the truck and then we have a secondary bracket, it attaches to this one with some screws and that holds the brake controller in place. It is also easy to remove the brake controller easily, if you want to transfer between different vehicles. If you want a permanent setup, you could also use this included metal bracket as well. Let's go ahead and put our small bracket in place with a Phillip's head screwdriver to run the screws in. Always double check and make sure there is nothing behind it before you run your screws in. Make sure it's straight where we want it and then we'll install the second screw. We'll go ahead and use machine screws that are also included with the brake controller as the rest of the hardware. Just push it in using a Phillip's screwdriver, we'll install the machine screws. This will cut their own threads into the plastic bracket. By the way, you can also use the screws that we used for our circuit breakers, they will work in the same place as well. A small stubby screwdriver works in a tight situation like this. Let's go ahead and take our wire harness, plug it into the back of the brake controller till it clicks and then these corners right here will go into the corners of the bracket and it will snap into place. Next, we'll take a few moments and zip tie our wires, once again making sure they are safe and secure and don't interfere when working with the pedals. I'll use a small piece of inaudible 00:16:25 material here, to help hide the color of the wires. You can also use electric tape to accomplish the same thing. Back under the hood, we'll go ahead and hook up our wires. Let's start with the positive side first. We'll loosen up this nut using a 12 millimeter socket. Let's put our 2 ring terminals on there and replace the nut. Now we will go over to the negative side of our battery and we'll use a 10 millimeter socket for that side. Let's go back to our brake controller and we've got the screen lit up, so that shows us we've got power. At this point, it's a good idea to go ahead and plug up the trailer and try it out. With the trailer hooked up, we can see the display changes and it shows a small icon of a truck and trailer. That will tell us we have good connection to our trailer brakes and all you got to do now it take it on a couple of test drives and adjust the brake controller to your liking. That will finish it for the Tekonsha Prodigy P3 Trailer Brake Controller, part number 90195 on this 2010 Nissan Frontier.

Customer Satisfaction Score:

97% were satisfied with this product

3% of customers were not satisfied

- Wrong item was ordered

- Did not arrive in time

- Package not accepted

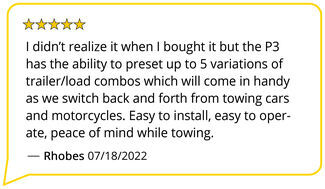

Ratings & Reviews

4.9

3537 reviews

See what our Experts say about this Tekonsha Trailer Brake Controller

- Can I Add Electric Brakes To A 1993 EZ Loader Boat TrailerHello Mike. It sounds like you are wanting to add electric brakes to your boat trailer that currently has no brakes. This is possible, but you will first need to make sure that your axle is equipped with a brake flange at the base of the spindle. The brake flange is necessary for adding brakes. If you do have a brake flange, you will next need to determine your bearing sizes. Electric brakes will require new hubs and drum assemblies, and we need to be sure that there is a drum available...

view full answer... - Hitch, Weight Distribution and Brake Controller Recommendations for a 2017 Toyota Sienna XLEWe can get you everything you need for towing with your 2017 Toyota Sienna XLE. By plastic shield, I believe you are referring to the appearance panel underneath the Sienna, and that will have to trimmed a bit in each of the hitches available for the vehicle. A great Class III hitch would be the Curt # C13105, which is rated for weight distribution and has been given a nearly 5-star review on our site by the over 500 customers that have rated it. As for a brake controller, the wireless...

view full answer... - Will The Curt Echo Manual Override Button C83HR Work Without The App?Hey John, good question. The app must be running in order for the separate manual override button part # C83HR to work. If your phone is not connected to the controller with the app running, the button will not do anything. I know the connectivity issues can be frustrating, but it might not necessarily be something you are doing wrong so much as the controller just being unreliable. This is by far the most common complaint we get about the Curt Echo # C51180 wireless controller. Most...

view full answer... - Difference Between Curt & Draw-Tite Trailer Hitches For 2018 Jeep Wrangler UnlimitedHi Ken, Starting with the wiring harness, I can verify for you the correct fit for the 2018 Jeep Wrangler Unlimited without a tow package is indeed the T-One Vehicle Wiring Harness with 4-Pole Flat Trailer Connector # 118786. Then for the hitches, the biggest difference between the Curt Trailer Hitch Receiver # C13392 and Draw-Tite Trailer Hitch Receiver # DT78MR is the length of the receiver. The Draw-Tite has a shorter receiver that can make it a bit more of a pain to add a ball mount...

view full answer... - Comparing the Universal Installation Kit # ETBC7 and the 7-Way RV Upgrade Kit # ETBC7LThere are a few differences between the Universal Installation Kit part # ETBC7 and the 7-Way RV Upgrade Kit part # ETBC7L. The biggest one is that part # ETBC7 comes with both the power and brake output wire you will need to run to the cab/battery whereas the part # ETBC7L only comes with the power wire you will need to run to the battery. The reason for this is because part # ETBC7L is geared more towards wireless brake controllers like the Curt Echo Mobile Trailer Brake Controller part...

view full answer... - Disc Brake Conversion Kit For 2021 Grand Design Solitude 310GKR With 7,000 lb AxlesHello Rick, thanks for reaching out. The 7,000 lb axle on your 2021 Grand Design Solitude 310GKR uses a standard bearing combination, so finding compatible disc brakes will be easy. Here is what I recommend: - DeeMaxx Disc Brake Kit - 13" Hub/Rotor - 8 on 6-1/2 - Maxx Coating - 9/16" Bolts - 7K # DE68YR - Hydrastar Electric Over Hydraulic Actuator Kit for Disc Brakes - 1,600 psi # HBA16-252-82 The disc brake kits are enough for one axle, so you will need two kits if you want brakes on...

view full answer... - Parts Needed to Add 7-Way to 2024 Hyundai Palisade LimitedThe factory wiring for both the 2023 and 2024 Hyundai Palisade has been a complicated subject. The pre-wiring you're referring to is not an actual trailer connector. You should have factory wiring and connectors which will allow you to add an OEM 7-way. I understand it says they all have this, but I would make sure you can find it on your particular vehicle if you plan to use it. There have been a lot of reports on forums where people said the connection was missing. At this time, nobody...

view full answer... - Will the Redarc Tow-Pro Liberty Controller Work with a 2023 Ford RangerHey Jacques, thanks for reaching out! The Redarc Tow-Pro Liberty # RED52VR will work just fine on your 2023 Ford Ranger, and it will install by splicing into a bundle of wires under your driver side dash. We have a video of this same process of the Prodigy P3 # 90195 on a 2021 Ranger that I'm linking for you to reference, but we don't have anything of the Liberty on a Ranger at this point in time. I'm not sure why we don't have this listed out to fit "with the tow package", but I'll send...

view full answer... - What is the Difference Between the Tekonsha Prodigy P2 and the P3 Brake ControllersActually, the P3 now has the upgraded axis accelerometer like the P2. The Tekonsha P3 Trailer Brake Controller # 90195, will work with both electric over hydraulic brakes on the trailer as well as electric brakes. It has a menu option on the display that allows the user to switch between the two systems. I have included a link to the installation details for the P3. The P2, # 90885, will also work with both electric brakes and electric over hydraulic brake systems but the mode is selected...

view full answer... - Parts Needed For Towing a Camper Behind a 2023 Toyota Tacoma Without Towing PackageSorry for the confusion on the details for the Tekonsha OEM Replacement Vehicle Wiring Harness # 22117 for your 2023 Toyota Tacoma. Since it can be used as a replacement for the OEM tapping into that connector is easier on those vehicles. Since you do not have the connector on your Tacoma you can simply use a Test Light # PTW2993 to find the correct wire on your brake switch which is on the brake pedal mount. Then you will be able to connect a controller like the Prodigy P3 # 90195. I personally...

view full answer... - No Trailer Connection on Tekonsha P3 Brake Controller 90195 on a 2000 Toyota TundraI would start by inspecting the connector on your trailer and the vehicle to make sure there is not corrosion in the connector which could be causing a bad or weak connection. If there is corrosion in the trailer side connector, you would need to replace it with 7-way Connector, part # A7WCB. For the replacement vehicle side connector, you would need Adapter 4 Pole to 7 Pole, part # 30717. For future use, I would recommend using Dielectric Grease for Electrical Connectors, part # 11755,...

view full answer... - How to Pick Out Brakes for 3,500 lb Boat Trailer with Tandem AxlesInstalling brakes on a trailer really isn't too bad. The install is pretty basic and a DIYer like yourself wouldn't have a problem at all. To determine the parts you need though we need to for sure know what axles/spindles you have so that we pick out the right parts. I attached a couple guides for that down below for you to check out. There are a lot of boat trailers that have great results with electric drum brakes so if that's a route you are interested in that's what I would recommend...

view full answer... - Parts Needed To Add Hopkins 7/4 Pole Connector To a 2020 Ford F-150 With Factory 4-WayI have a couple ways you can install the 7- and 4-Pole Trailer Connector Socket # HM40975 on your 2020 Ford F-150 with a 4-way flat factory connector. The first is going to be the easiest but is more costly. You will use the harness from the Curt 7-Way # C56413 and connect to the connector you found. The Curt harness will connect to the factory wiring as seen in the installation video I have linked near the bottom of the page. Otherwise we do have the Hard Wire Connector # 20147 which...

view full answer... - Troubleshooting a Tekonsha P3 Brake Controller that Reads Trailer Not ConnectedIf you sever the blue wire leaving the P3 controller part # 90195 leaving enough room to reconnect it and test the end of the wire leaving the controller with a circuit tester like part # PTW2993 you should see voltage when you slide the manual override lever. If not, then the brake controller is bad. If you see voltage there instead then the problem is somewhere on the brake output circuit of your vehicle or trailer. Corrosion on the trailer connector typically causes this problem. If...

view full answer... - Electric Over Hydraulic Brakes Don't Work w/Brake Pedal on Newer GM Trucks w/OEM Brake ControllerLike you said, many factory integrated brake controllers will not work well with electric over hydraulic trailer braking systems. Some of the newer versions of these controllers now have an electric over hydraulic mode. Check to see if any of your trucks have this mode and, if they do, if the braking starts working with the pedal. Otherwise there are a couple of solutions to solve this issue. First, there may be an adapter that will allow the factory controllers to work but it depends...

view full answer... - Trailer Hitch And 7-Way Wiring Package For 2019 Kia Sorento Without Factory Tow PackageHello Anton, thanks for reaching out. For your 2019 Kia Sorrento I recommend the etrailer Class 3 Hitch # e98843. This has a 2" receiver, 5,000 ls towing capacity and 750 lb tongue weight capacity. Install video and instructions are linked for you below. For your wiring, there are two kits you will need to complete everything. You will need the Tekonsha T-One Wiring Harness # 118583, as well as the Universal Installation Kit # ETBC7. These will contain everything you need to wire your...

view full answer... - Troubleshooting Only One Side of Trailer Brakes Locking UpYes, when the electric signal is sent from the Tekonsha Prodigy P3 Trailer Brake Controller # 90195 to the trailer's brakes, it should cause both sides to lock up. Since only one side is locking up, it could indicate that one brake assembly needs to be manually adjusted. I attached a video that shows how to do this process. If that doesn't get it to respond then there is possibly an issue with the wiring going into the brake assembly which you can test using a circuit tester like # PTW2993....

view full answer... - Recommended 7-Way Trailer Wiring On 2007 Ford E-350 Super Duty VanIf you don't already have a 4-way wiring harness, we need to start there to get your 7-way. For a 4-way, I recommend the Curt T-Connector Vehicle Wiring Harness with 4-Pole Flat Trailer Connector # C56020 which plugs in behind the tail lights of your 2007 E350. You will have to remove the tail light assemblies and interior trim paneling to access the factory connections. I've attached a video to help. Then you will use the Universal Installation Kit for Trailer Brake Controller - 7-Way...

view full answer... - Showing 12V Power On The Red Wire From Tekonsha Prodigy P3 PigtailIt sounds like you are hardwiring the Tekonsha Prodigy P3 Trailer Brake Controller part # 90195. The red wire should only show power at the brake controller when the brake pedal is depressed. It should be connected to the stop light wire on above the brake pedal that only shows power when the brake is depressed. If it is showing power when the brake pedal is not depressed than it is not connected to the correct wire at the brake pedal. The 12V should be showing on the black wire which...

view full answer... - Does Prodigy P3 Brake Controller Eventually Shut Itself Off With No ActivityAfter 10 minutes of inactivity the Prodigy P3 part # 90195 will go into sleep mode which means it basically shuts itself off without losing presets.

view full answer... - Timbren Axle-Less Trailer Suspension System Rated for Higher Than 2,000 PoundsThe Timbren Axle-Less Trailer Suspension System, part # A20RS545, is rated for a total of 2,000 pounds. Essentially, it's designed to work in place of a suspension system and a 2,000 pound standard axle. If you need a 3,500 pound system use part # A35RS545 that has idler hubs with the same 5 on 4-1/2 bolt pattern. If you want to add brakes instead use part # A35RS545E that includes the hub and drums, as well as the brake assemblies. There really isn't anything to retrofit. You just...

view full answer... - Stealth Hitch And Towing Kit For 2024 Volvo XC90Hello Geoff, thanks for reaching out. We do offer a stealth hitch and wiring package for the 2024 Volvo XC90. For that, I recommend the following: - Stealth Hitches Hidden Trailer Hitch Receiver w/ Towing Kit - Custom Fit - 2" # SH27FRT This comes with everything you need to pull a trailer. You get the stealth hitch and rack receiver, plus the towing kit with active harness. The hitch has a max towing capacity of 6,000 lbs so this will be plenty strong for a 2,500 lb enclosed trailer....

view full answer... - Parts Needed to Add Disc Brakes to Trailer with Dexter 12K Axles w/ Electric Drum BrakesThe Kodiak # K2R1258L12 Disc Brake Kit is compatible with a 12K Dexter axle with a 7-bolt brake mounting flange. Your current wheels/hubs should have an 8 on 6-1/2 inch bolt pattern. You'll also need an electric over hydraulic brake actuator, a brake line kit, a break away system and a brake controller that's compatible with electric over hydraulic brake systems. For the electric over hydraulic actuator, I'd recommend going with the Hydrastar # HBA16. Our install techs have found it to...

view full answer... - How to Convert a Trailer with Surge Brakes to Electric Over Hydraulic BrakesYou can convert surge brakes to an electric over hydraulic braking system. To do this, you will need an electric over hydraulic actuator and a brake controller. For an electric over hydraulic actuator, I recommend looking at the Carlisle HydraStar units. If your trailer has drum brakes, you will want part # HBA-10. If your trailer has disc brakes, then you will want part # HBA16. I have also attached a link to all of our electric over hydraulic actuators for you to check out your options. The...

view full answer... - Troubleshooting Brakes Staying on When Connected to 7-Way on 2012 Nissan PathfinderThank you for all of the details. I'm glad to hear that all of your lighting functions are working properly. That takes quite a bit of troubleshooting out of the equation. The red wire that was referenced looks to carry the reverse light function. If your trailer has reverse lights then you definitely want to make that connection. For the answer page you are referencing the customer was looking to use the Adapter # 37185 along with the T-One # 118266 which is the equivalent of the Curt...

view full answer... - Towing Setup with Brake Controller, Mirrors and Weight Distribution for 2015 Nissan Frontier Hey Brad! Appreciate you reaching out. Looks like you’ve got an awesome setup with the Frontier and that trailer low miles too, that’s sweet! I’d recommend the Redarc Tow-Pro Elite part # RED44FR for your brake controller — it’s super clean because it's just a little knob on your dash and works awesome for normal towing or even rougher roads. You’ll also need the plug-in adapter part # 3050-P to make it plug straight into your truck’s tow package without splicing anything. For weight...

view full answer... - Brake Controller and 7-Way Recommendation for 2009 Nissan PathfinderTo install a 7-way on your 2009 Nissan Pathfinder you'd need to start with the part # 118281 which is a confirmed fit. Then to install a brake controller you'd be able to use a plug and play style adapter like the # 3050-P and you'd be set. For a brake controller I would recommend the Prodigy P3 Brake Controller part # 90195. This is our best selling brake controller because of how well it works and how easy it is to setup. This is a proportional brake controller that senses the amount...

view full answer... - Factory Brake Controller Port Location on 2017 Nissan TitanTo install the Draw-Tite Activator Trailer Brake Controller # 5504 that you referenced to your 2017 Nissan Titan, all you will need is the Plug-In Wiring Adapter # 3050-P if the truck is equipped with the factory 7-Way. One end of the harness will plug into the brake controller itself, while the other end will connect directly to the factory port on your Nissan Titan. The factory brake controller port should be located behind the dash, on the left hand side by the emergency brake pedal....

view full answer... - Is Aftermarket Trailer Hitch Safe to Use Over OEM Trailer Hitch for a 2017 Nissan PathfinderYes, even though the Draw-Tite Max-Frame Trailer Hitch Receiver # 76031 only uses 6 bolts as opposed to the 10 bolts for the OEM trailer hitch it has gone through an extensive amount of stress tests to ensure that the 6,000 lb trailer towing rating is completely safe. I highly recommend going with this over the OEM for your 2017 Nissan Pathfinder so that you can add some extra components. For a cost-effective brake controller that is reliable I recommend the Tekonsha Primus IQ # TK90160....

view full answer... - Replacement 7-Way Connector Needed for 2007 Nissan FrontierIf you need to change out the complete wiring harness on your 2007 Nissan Frontier then you will need the Replacement Wiring Harness # 118267. If you have the US carr connector still intact then you can use the Pollak # PK11893, but if you just have bare wires you would want the Pollak # PK12-707E instead. I have attached a picture with the typical wiring setup for a vehicle side 7-Way. You will want to use a Circuit Tester # PTW2992 to verify the different functions of your wiring if...

view full answer... - 2006 Nissan Armada Requiring Additional Relay For Trailer WiringSome models require a fourth relay, one of the blue relays from the Curt Relay Kit # 57000. It is installed under the dash on the left side of the steering column. There is a socket there to plug in the relay that will activate the tow package tail lights on the Armada, if it was not installed at the factory. Since you already installed the Relay Kit, part # C57000, adding this 4th relay should take care of the problem with the running lights.

view full answer... - Weight Distribution and Brake Controller Recommendation for a 2011 Nissan FrontierFor a weight distribution system that offers sway control and the ability to backup without removing the spring bars or sway control, I recommend looking at our Blue Ox SwayPro systems. I have attached a link to all of the SwayPro systems for you to check out. In order to choose the best weight distribution for your truck and trailer, you will want to determine the total tongue weight of your towing setup. The total tongue weight will include the loaded and ready to tow tongue weight...

view full answer... - Recommended Brake Controller for 2018 Nissan Titan With Factory 7-WayFor your 2018 Nissan Titan I very strongly recommend going with the Redarc Tow-Pro Elite item # RED44FR over the Curt Spectrum item # C51170, which does use Wiring Adapter item # C51382 to connect to your 2018 Nissan Titan. The Redarc Tow-Pro item # RED44FR, which you can install in your '18 Titan with Wiring Adapter item # 3050-S, is by far the superior option because it is not only extremely effective and responsive but its manual control knob makes it simple to use; the Tow-Pro can...

view full answer... - Testing Prodigy P3 Brake Controller Power Output on 2011 Nissan PathfinderThe Tekonsha Prodigy P3 # 90195 is a great fit for your 2011 Nissan Pathfinder using the wiring harness # 3050-P. There is no additional relay or anything required. Since you know there is power getting to the controller the best way to test if power going out from the controller is to test the blue brake controller output wire. You can do this behind the harness or you can do this at the 5 o'clock pin of your 7-way trailer connector using a circuit tester like # PTW2993. Because...

view full answer... - Where to Connect the Adapter to Install a Curt Brake Controller in a 2017 Nissan PathfinderTo install a Curt Brake Controller, like the Discovery # C84VV, on your 2017 Nissan Pathfinder you will simply need to plug the Custom Wiring Adapter # C51382 under your dash like you mentioned. I am attaching a video where one of our install guys installed a Tekonsha Prodigy P2 # 90885 in a 2013 Pathfinder using the Tekonsha Wiring Adapter # 3050-P. If you skip to the 2:45 mark you can see where he plugs in the adapter for the Prodigy P2. Your Curt adapter will plug into the same place.

view full answer... - Trailer Hitch Receiver and Wiring Harness for a 2017 Nissan Titan with No Tow PackageEven though your 2017 Nissan Titan doesn't have the tow package it should still have the standard round connector to install trailer wiring behind the rear bumper. Part # N40975 includes the 7-way and 4-way connector that plugs right into your truck, as well as the relays to installto activate the wiring. I've linked a video that shows the install on a 2010 Titan for you. The process is the same. With a trailer that large it's likely to hve brakes so you need a brake controller. I...

view full answer... - Can Tekonsha Brake Controller Install in 2020 Nissan PathfinderHey Bett, yes you can use your Tekonsha Pilot in your 2020 Nissan Pathfinder and you'll just need to use the install harness part # 3050-P.

view full answer... - How Long is the Electric Brake Controller Pigtail Adapter For Tekonsha Brake ControllersI went out to the warehouse and pulled the Tekonsha Plug-In Wiring Adapter for Electric Brake Controllers, # 3050-P and found that it is 31-3/4 inches long overall, including the connectors. I produced a short video showing the length of the adapter for you. The # 3050-P harness is compatible with the Prodigy 2, # and all of the Tekonsha brake controllers in current production. At this time the manufacturer lists this harness for the 2004 - 2012 Nissan, Armada, All Styles. This could...

view full answer... - Recommended Trailer Hitch Receiver, Wiring, and Weight Distribution for 2013 Nissan Armada 4x4For your 2013 Nissan Armada, I recommend the Curt Trailer Hitch Receiver # 13188. This will be able to tow your trailer with 1 horse without weight distribution, but you will most likely need the weight distribution system for 2 or 3 horses. It will also help with sway control, so I would use it no matter the number of horses. For your wiring, if you don't have the factory 7 way, I recommend the Vehicle Wiring Harness Kit with 4 Pole Trailer Connector # C59236 along with the # ETBC7...

view full answer... - Availability of Wiring Harness for 2024 Nissan Pathfinder Rock Creek Using Redarc Tow-Pro LibertyHey Charles! Redarc doesn't have a specific wiring harness but you can still make the Redarc Tow-Pro Liberty # RED52VR you ordered plug and play. I see you ordered the Tekonsha # 3050-P as well. This will plug into the factory port under your dash but it won't fit into the Liberty. You will also need the Redarc Tow-Pro Wiring Adapter for Tekonsha Brake Controller Harness # 331-TPH-017 to make the two compatible. What kind of trailer will you be towing?

view full answer... - Looking For Brake Controller For 2024 Tesla Model YHello Randolph, thanks for reaching out. We do have brake controller options for the 2024 Tesla Model Y. Does your Tesla already have a 7-way trailer plug? If not, you will first need to install the ZCI Circuit Protected Vehicle Wiring Harness # 119250KIT along with the Universal Installation Kit # ETBC7. This will give you a 4-flat, 7-way and all the necessary wires for a brake controller. For that, I recommend the following: - Redarc Tow-Pro Liberty Brake Controller w/ Universal Wiring...

view full answer... - Should I Get a Proportional or Time-Delayed Brake ControllerThe best brake controller option to go with is one that activates the brakes proportionally instead of time delayed. A proportional brake controller will activate the trailer brakes at the same time and with the same intensity as the tow vehicle brakes whereas a time delayed brake controller will activate the brakes at a predetermined time and intensity once the brake pedal is pressed in the tow vehicle. This can cause uneven wear of the brakes and tires. Proportional brake controllers...

view full answer... - Brake Controller for 2024 Nissan Pathfinder Towing Trailer with Electric Over Hydraulic BrakesHey Jeffrey, so we have just what you are looking for with the Prodigy P3 part # 90195. This controller has an EOH setting to allow it to be used with the type of brakes your trailer will have and is widely considered to be the best controller on the market. To install it all you need is the install harness # 3050-P.

view full answer... - Recommended Trailer Harness Wiring For 1996 Ford F-250 To Tow Fifth Wheel TrailerThere are a few scenarios here. If you have a factory-installed 4-way connector then that makes a difference down the road when installing a brake controller. There may be a brake controller port under the dash on your F-250 and an adapter can be used with a brake controller. The first thing you want to do is find out if your 4-way connector is operational. If it is working, that may save you some money. You can use a circuit tester like part # PTW2993 for that. Have someone sit in the...

view full answer... - Location of Brake Controller Adapter Port to Install Prodigy P3 on 2019 Nissan PathfinderTo install the Prodigy P3 Trailer Brake Controller # 90195 in your 2019 Nissan Pathfinder you can find the brake controller port directly under the dash as in the accompanying photo. This will allow you to plug in the Tekonsha Plug-In Wiring Adapter for Electric Brake Controllers # 3050-P. I recommend going to the linked video showing this brake controller being installed on a Pathfinder; if you go to the 6:30 mark you can see the exact location.

view full answer... - Plug-And-Play Electric Trailer Brake Adapter Harness For A 2022 Nissan Frontier Tekonsha has not released any information on when that might be available, but I do have a solution. For your 2022 Nissan Frontier, you can use the Redarc Tow-Pro Elite Trailer Brake Controller # RED44FR, with the plug in adapter # RED39FR. This is a plug-and-play harness, that will plug underneath the dash on your 2022 Frontier like you had mentioned. If you don't already have a 7 way located at the rear of your vehicle, # ETBC7 is a simple to install kit that will work great with your...

view full answer... - Brake Controller Install and Recommendation for a 2007 Nissan FrontierWe had a customer with a 2007 Nissan Frontier just like yours have trouble finding the port to install the brake controller harness needed to plug in the # 3050-P come back and say he was able to find it above the gas pedal. I attached the picture he sent us that shows where it was. For a brake controller I would recommend the Prodigy P2 Brake Controller part # 90885. This is our best selling brake controller because of how well it works and how easy it is to setup.

view full answer... - Recommended Brake Controller For 2019 Nissan Armada With Factory Tow PackageWe can get your 2019 Nissan Armada with the factory tow package set up with a trailer brake controller, and since you have the tow package all you'll need is the brake controller and wiring adapter. For your '19 Armada I highly recommend an option from Tekonsha: - Tekonsha BRAKE-EVN Trailer Brake Controller # TK63VR - Tekonsha Plug-In Wiring Adapter # 3050-P I really like the BRAKE-EVN # TK63VR because it is the best overall value for a trailer brake controller; the reason for that is...

view full answer... - What Wiring do I Need for a 7 Way on the Back of My 2010 Nissan Frontier for Brake Controller?Hello Mike, I’m glad you wrote in because there’s a better and easier option for you. To get a 7-way on the back of your 2010 Nissan Frontier and have it ready for a brake controller, you’ll want to install the T-One Vehicle Wiring Harness with 7-Way Trailer Connector # 118266. I’ve attached an install video so you can see exactly what’s involved. You don’t need to install a brake controller right away, your truck will be ready for it whenever you are. When that time comes, the Tekonsha...

view full answer... - Parts Needed to Add a Brake Controller to a 2024 Nissan Frontier Without Tow PackageIf you're buying it without the tow package, Norm, then the wiring is not going to be at the rear. To install a brake controller you're going to first need to add the T-One Vehicle Wiring Harness with 7-Way Trailer Connector # 118266 which will plug into your factory harness and provide a 7-way to the rear. From here, you can then add a brake controller like the Tekonsha Prodigy P3 Trailer Brake Controller w/ Custom Harness # TK59ER.

view full answer... - Parts Needed to Install Brake Controller in 2018 Nissan Frontier SV Hey Joe, so yes you can install a brake controller like the P3 part # TK59ER which is custom fit for your 2018 Nissan Frontier which comes with the correct install harness for your vehicle. With just this part number you'd have everything needed to operate the brakes of your trailer.

view full answer...

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.