Why is 10 or 12 Gauge Wire Recommended for Electric Brake Assemblies

Published 04/15/2019

Products Featured in This Question

Question:

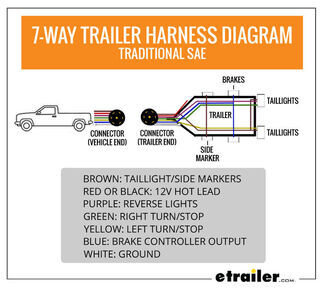

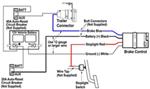

The reason that 10 Gauge # 10-1-1 or 12 Gauge # 12-1-1 wire is recommended for 10" brake assemblies, like part # AKEBRK-35-SA, is because they pull more power than the lights on your trailer. I believe the green wire you are referring to carries the right turn/stop lighting functions as you can see from the attached photo of a trailer side 4-Way. The 14 and 16 gauge wires are too small for the amount of power needing to get to the brake assemblies and they could potentially get too hot, fail, or catch fire. If you only have a 4-Way on your trailer then you also need to install a 7-Way like the part # A10-7W6 or the part # 277-000141 which comes with a junction box for better wire management. The brake signal for your trailer brakes should be coming from a brake controller like the Prodigy P3 # 90195 that is mounted inside your tow vehicle cab. This brake controller allows you to control the amount of brake power that is being output and has a manual override in the event that emergency stopping is needed. I am attaching a helpful article that gives you more info about trailer wiring that you can reference as well as a video of the junction box being installed that you can check out.

asked by: Ronald R

Expert Reply:

The reason that 10 Gauge # 10-1-1 or 12 Gauge # 12-1-1 wire is recommended for 10" brake assemblies, like part # AKEBRK-35-SA, is because they pull more power than the lights on your trailer. I believe the green wire you are referring to carries the right turn/stop lighting functions as you can see from the attached photo of a trailer side 4-Way. The 14 and 16 gauge wires are too small for the amount of power needing to get to the brake assemblies and they could potentially get too hot, fail, or catch fire.

If you only have a 4-Way on your trailer then you also need to install a 7-Way like the part # A10-7W6 or the part # HS381-9000 which comes with a junction box for better wire management. The brake signal for your trailer brakes should be coming from a brake controller like the Prodigy P3 # 90195 that is mounted inside your tow vehicle cab. This brake controller allows you to control the amount of brake power that is being output and has a manual override in the event that emergency stopping is needed.

I am attaching a helpful article that gives you more info about trailer wiring that you can reference as well as a video of the junction box being installed that you can check out.

Product Page this Question was Asked From

etrailer Electric Trailer Brakes - Self-Adjusting - 10" - Left/Right Hand Assemblies - 3.5K

- Trailer Brakes

- Electric Drum Brakes

- Standard Grade

- Self Adjust

- 10 x 2-1/4 Inch Drum

- 3500 lbs Axle

- 13 Inch Wheel

- 14 Inch Wheel

- 15 Inch Wheel

- etrailer

more information >

Featured Help Information

Miscellaneous Media

Continue Researching

- Article: Trailer Wiring Diagrams

- Shop: Brake Controller

- Shop: etrailer Electric Trailer Brakes - Self-Adjusting - 10" - Left/Right Hand Assemblies - 3.5K

- Search Results: 10 gauge wiring

- Search Results: trailer breakaway kit

- Search Results: trailer wiring

- Search Results: brake wire

- Search Results: bumper cap

- Search Results: trailer junction box

- Q&A: What Gauge Wire Should be Used to Wire Trailer Brakes

- Search Results: trailer hubs and drums

- Article: Wiring Trailer Lights with a 7-Way Plug (It's Easier Than You Think)

- Shop: Easy Grease Trailer Hub and Drum Assembly for 3.5K Axles - 10" - 5 on 4-1/2 - Pre-Greased

- Shop: 12 Gauge 2 Conductor Jacketed (Brake) Wire Per Foot

- Shop: Deka Jacketed 2 Wire, 10 Gauge, Brake Wire - per Foot

- Shop: Dexter Electric Trailer Brakes - 10" - Left/Right Hand Assemblies - 3.5K

- Shop: Universal Installation Kit for Trailer Brake Controller - 7-Way RV and 4-Way Flat - 10 Gauge Wires

- Shop: etrailer Trailer Wiring 7-Way Upgrade Kit w/ Junction Box and RV Style Connector

- Video: etrailer Easy Grease Trailer Hub and Drums Installation - 2020 K-Z Sportsmen Classic Travel Trailer

- Article: How to Measure Your Trailer Wheel Bolt Pattern

- Video: Let’s Check Out the Ring Terminal

- Q&A: Wire Gauge of 10 Inch Electric Brake Assembly

- Q&A: Can I Replace Just a Brake Magnet or do I Need to Replace the Assembly

- Shop: Suspension Enhancement

- Q&A: Troubleshooting Hopkins Brake Controller that Is Not as Strong as Voyager

- Q&A: How to Pick Out Brakes for 3,500 lb Boat Trailer with Tandem Axles

- Article: Parts Needed to Add Electric Drum Brakes to a Trailer

- Video: Miro-Flex Thinline LED Trailer Clearance or Side Marker Light: The Breakdown

- Q&A: Torque Spec for Tightening Trailer Brake Assemblies to Trailer Spindle

- Video: Trailer Brakes and Wiring Installation

Ronald C.

4/15/2019

The reason that 10 Gauge # 10-1-1 or 12 Gauge # 12-1-1 wire is recommended for 10" brake assemblies, like part # AKEBRK-35-SA, is because they pull more power than the lights on your trailer. I believe the green wire you are referring to carries the right turn/stop lighting functions as you can see from the attached photo of a trailer side 4-Way. The 14 and 16 gauge wires are too small for the amount of power needing to get to the brake assemblies and they could potentially get too hot, fail, or catch fire. If you only have a 4-Way on your trailer then you also need to install a 7-Way like the part # A10-7W6 or the part # 277-000141 which comes with a junction box for better wire management. The brake signal for your trailer brakes should be coming from a brake controller like the Prodigy P3 # 90195 that is mounted inside your tow vehicle cab. This brake controller allows you to control the amount of brake power that is being output and has a manual override in the event that emergency stopping is needed. I am attaching a helpful article that gives you more info about trailer wiring that you can reference as well as a video of the junction box being installed that you can check out.