Testing Trailer Brake Magnets for Proper Function

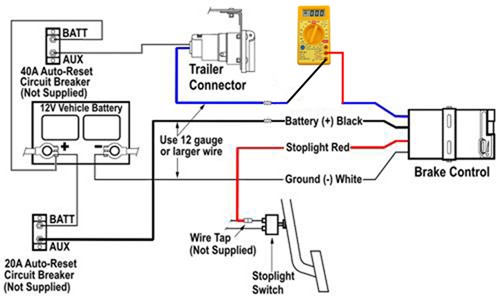

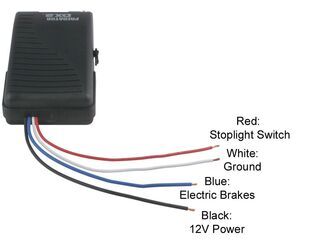

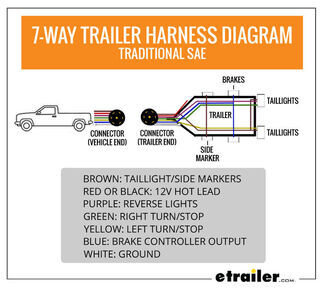

Testing with Trailer Connected to the Vehicle

Electromagnet Specifications

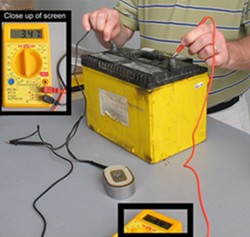

Testing Individual Brake Magnets

Individual Brake Magnet Amperage Specifications

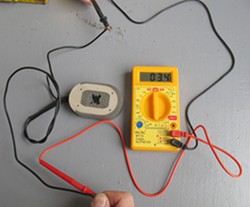

Testing Individual Brake Magnet for a Short

Testing Brake Magnet Resistance

Brake Magnet Resistance Specifications

Pete

5/21/2025

I tested each magnet last night. 4 brake trailer. I am only getting 2.7 ohms at each magnet. I’ve replaced the brake wire, the brake controller and now tested the magnets. I am only getting 2.7 ohms at all 4 magnets. What am I missing as I am getting intermittent brake overload. One magnet was a little lack of response when testing with the meter. So I am possibly thinking short in that magnet. Please help?????

Pete

5/21/2025

Robin H.

5/22/2025

Brian J.

6/12/2025

Glynn J.

7/17/2025

Paul

4/9/2024

Hello, I have been trying to test my 2003 GMC 1500 5500 lb towing vehicle with 5500 lb travel trailer elec brakes. I have noticed during wheel bearing inspection that one one the four trailer Brake drums did not have any marks from the elec magnet. Thus making me think that one magnet was not making contact with drum. This would be the front right side. I have a Tekonsha Prodigy P3 controller. When I jack up the front axle to test the brakes by putting a 1x4 from truck seat With key on trailer plugged into truck both trailer wheels turn, even with break- away key removed wheels will rotate. So I suspected a ground problem.and replaced two ground lugs and cleaned the connection to frame. Now the wheels of the trailer lock up while removing the break away key and while pulling manual over ride lever on controller. But when I place the 1x4 from truck seat to foot brake pedal the wheels on trailer do not lock up. May the foot pedal with not apply until I'm on the road, I don't know. Any ideas? Thanks, Paul

Sherman

4/27/2024

Jeremy

9/22/2023

I am not electrician, but on a trailer with four 10" brakes, if min amperage at each magnet is 3.2 amps, how are you going to get the stated min combined 15 amps at the tongue? It seems to me that min combined at the tongue should be 12.8 (3.2*4) amps or each individual magnet min amps should be 3.75 (15/4).

Mike L.

9/25/2023

Jeremy

9/25/2023

Mike L.

9/25/2023

Rob L.

6/18/2024

Jesse

9/25/2025

Andy W.

11/10/2023

Chad

8/11/2023

The information contained in the section "Testing with Trailer Connected to the Vehicle" is the same as I see on other websites as well, but when I try to test amperage this way on my Tekonsha Prodigy P2 Trailer Brake Controller it tells me no connection and won't output. It sees the connection fine before adding the multimeter inline to test. How can I test the overall trailer brake amperage if this doesn't work and why would it not see the connection with the multimeter inline? Thanks

Mike L.

8/14/2023

The G.

9/6/2023

Miley

7/28/2022

I have not gotten any answers out of Ford: . . . . .So went to a large dealer and talked to the service manager about the warning message that fills the entire dash “WIRING FAULT ON TRAILER”. When this message appears no other information appears on the dash, which requires you to hit the OK button while braking to clear a message as you are driving with no apparent cause or meaning. The dealer has no way to troubleshoot why this warning is coming on. He has no technical detail on how much brake current is too much at any given speed or how much input to the microprocessor is receiving from the other computers on the truck. Since there is no interest from Ford in fixing the Hazard warning label while using the brakes to slow or stop the F-350 truck. The manual under Information Display Warning Messages has this statement: “the trailer brakes may be drawing too much current” what does that mean ? The dealer does know what that number is. I never have that warning light appear when pulling a double axle trailer with 4 brakes. I appears often a lot when pulling a triple axle trailer with 6 brakes. I think the Ford trailer brake system cannot handle the current draws when all 6 brakes are engaged. But with no spec supplied to the dealer and no way to test what that trip point is. The microprocessor controls all of these items yet the dealership cannot check or verify any of these operations. • The trailer brake controller is equipped with a feature that reduces output at vehicle speeds below 11 mph (18 km/h) so trailer and vehicle braking is not jerky or harsh. This feature is only active when applying the brakes using your vehicle's brake pedal, not the controller. • The controller interacts with the brake control system and powertrain control system of your vehicle to provide the best performance on different road conditions. • Your vehicle's brake system and the trailer brake system work independently of each other. Changing the gain setting on the controller does not affect the operation of your vehicle's brakes. What I need Ford to do is help the dealer run checks or simulations to stop the need for the Hazard Notification with no solution to be displayed on the dash that block all normal displays that are shown on the dash. Trailer Fault Indicator on Dash Can you change the parameters on the Ford brake controller ? Can the dealer change the upper current limit on the brake controller when engaging 6 brakes on a triple axle trailer ? I looked in the Manual as to why does the trailer fault display on the dash The dealer tech does not have all the parameters on the brake control That’s what I’m requesting are the parameters that the brake controller sees before the display is shown on the dash I think the random display is caused by the trailer brakes exceeding the current draw limit built into the brake controller. This display warning only occurs with this triple axel trailer toy hauler, no other trailer causes the warming. But the other trailers do not have 6 electric brakes connected to the F-350. When the brakes are applied too hard all 6 brakes draw too much current versus a dual axle trailer with only 4 brakes needing current. The dealer has done the simple test that dealers can do, they find no problems with the very basic test. A trailer repair place said there is no problem with the trailer brakes. And the warning hazard does not occur on an ongoing regular basis only when the brakes are applied too hard. I push the OK button everything is fine until I apply the truck brakes too hard, which causes all 6 brakes on the trailer to engage, this again exceeds the upper limit that the brake controller thinks is excessive and displays the warning on the dash. Most trailers only have two axles or 4 brakes, not 6. This exceeds the controller trip point for a higher than normal current draw. The solution is to program the control to a higher trip point due to 6 trailer brakes drawing higher Amps during a normal braking operation. In the Ford manual on page 296/666 it states this: TRAILER BRAKE MODULE FAULT Displays in response to faults sensed by the trailer brake controller, accompanied by a single tone. If this message appears, contact an authorized dealer as soon as possible for diagnosis and repair. The controller may still function, but with degraded performance. WIRING FAULT ON TRAILER Displays when there is a short circuit on the electric brake output wire. On page 297/666 it states this: If this message displays, with no trailer connected, the problem is with your vehicle wiring or trailer brake controller. Contact an authorized dealer. If the message only displays with a trailer connected, the problem is with the trailer wiring. Consult your trailer dealer for assistance. This can be a short to ground (such as a chaffed wire), short to voltage (such as a pulled pin on trailer emergency breakaway battery) or the trailer brakes may be drawing too much current. Points to Remember Note: Do not attempt removal of the trailer brake controller without consulting the Workshop Manual. Damage to the unit may result. • Adjust the gain setting before using the trailer brake controller. • Adjust gain setting, using the procedure above, whenever road, weather, trailer, or vehicle loading conditions change from when the gain was initially set. • Only use the manual control lever for proper adjustment of the gain during trailer setup. Misuse, such as application during trailer sway, could cause instability of the trailer or tow vehicle. • Avoid towing in adverse weather conditions. The trailer brake controller does not provide anti-lock control of the trailer wheels. Trailer wheels can lock up on slippery surfaces, resulting in reduced stability of trailer and tow vehicle. • The trailer brake controller is equipped with a feature that reduces output at vehicle speeds below 11 mph (18 km/h) so trailer and vehicle braking is not jerky or harsh. This feature is only active when applying the brakes using your vehicle's brake pedal, not the controller. • The controller interacts with the brake control system and powertrain control system of your vehicle to provide the best performance on different road conditions. Thus controller has a microprocessor that handles all of these inputs from different systems on the F-350 truck.

Zack

10/10/2022

R.

9/22/2023

Chris C.

7/9/2022

Replaced all 4 trailer brakes with new shoes and magnets etc. after adjusting then very weak brakes. Adjusted them 3-4 times still the same. Tested the truck and it’s giving out 12 volts at trailer plug. Tested wires by brakes and when manual override lever for brakes is applied Im only getting 10 volts at each individual brakes. Tested the resistance of each magnet and it’s 2.7ohms. Range is 3.0 to 3.8 with 12 inch brakes does that mean my magnets are junk? Also I’m not hearing a constant humming noise at the brakes when voltage is applied. Does this mean the magnets aren’t energizing? I think I need new magnets just want to get opinion from experts. Thank you

David B.

7/12/2022

Jim J.

6/24/2022

I have a 2016 f 350 diesel and a Legend 24 ft aluminum trailer I just did a full brake job to trailer cause brakes where done and system was giving me a trailer disconnected message. Well everything new and still giving me that message. I have all lights working perfect but no brakes. Any thoughts Thanks Jim

David B.

6/27/2022

Efren

12/28/2022

Mike L.

12/28/2022

Andrew

7/15/2023

Mike L.

8/2/2023

David B.

6/20/2022

Wally

6/20/2022

David B.

6/20/2022

Davis

6/13/2022

when I pull emergency brake voltage drops to 10 volts from 12v and brakes very weak I've adjusted brakes and wires look good (trailer is 6 months old)

David B.

6/17/2022

Ed

6/10/2022

Just put new brakes on trailer that had minimal braking. install complete brakes with magnets ect. with trailer raised in the air when you apply the brake via the controller all brakes lock up. When trailer is on the ground hooked to truck then you activate controller fully the brakes slow the trailer but not very good. Adjusted brake shoes several times. Any help ?

David B.

6/11/2022

Paul H.

5/24/2022

My 2018 tundra flashes from trailer disconnected to connected This is a brand new axel I put on and wired, this has never happened while towing other trailers with brakes

David B.

5/25/2022

Ben H.

6/3/2022

Paul H.

6/3/2022

Christopher W.

4/1/2022

I have tested the resistance on all four of the brake magnets on my trailer. 3.0, 3.2, 3,2, and 3,2. However, when I check the amperage I am only getting 12.8 amps for the 12 in brake drum brakes. Do the brake magnets need to be replaced even though they are within spec? Using a prodigy P3 brake controller to check the amperage.

David B.

4/12/2022

Sparky A.

10/8/2021

I used a battery charger as a voltage source. I got a lower current than expected, even though the DC resistance check out. Ohm's law seems to be violated in my garage. But then I realized the "DC" output of a batter charger is not true "DC" but is usually full wave rectifier waveform. Therefore the magnet exerted inductive reactance on my battery charger voltage source, reducing the current. I'm just saying, be advised that a batter charger does not produce a true DC voltage.

Matthew K.

9/4/2021

I have two trailers and a brand new silverado 3500 hd work truck, On my dump trailer, I get " brakes connected" several moments later check trailer wiring. This goes back and forth on its own even with the truck just sitting there. Its been in the dealership twice but all the found was a blown trailer break fuse in the fuse box and a rubbed out nuetral between front of truck and connector. Need help on how to test the trailer for some mysterious issue. All trailer brakes appear to work.

Mike R.

10/24/2021

John

9/3/2021

In your picture for Individual Brake Magnet Amperage Specifications, you have the negative of the multi meter connected to the magnet and negative battery terminal. But in your dictation you say to connect the positive of the multi-meter to the magnet and positive battery terminal. Which is it? I connected the positive of the multi meter in line with the battery and brake magnet, then connected the negative of the brake magnet to negative on the battery. I got no reading on a brand new brake magnet, what is the problem?

Victoria B.

10/20/2021

Stephen B.

8/27/2021

Some great testing ideas and specs from a company that I have purchased many repair parts for my fifth wheel.

Al

8/17/2021

Got brake problems,magnets are humming,shoes are adjusted with some drag,still no brakes,these are new brake assemblies,whats going on?

Victoria B.

8/18/2021

Helpful Links

Glynn J.

1/25/2022

Les D.

1/26/2022

John

8/13/2021

I just recently picked up a 16 foot flatbed trailer with brakes. Someone has removed the brake harness from the axle forward. Both wires coming out of the brakes are green. There’s one of these go to ground and the other one to the power source on my seven wire plug? With both of them being green does it matter which one goes where?

Victoria B.

8/18/2021

Mac E.

5/24/2021

What if the code S.H. stays on when the trailer is disconnected? Does this indicate that the problem is with the truck wiring?

Jon G.

5/25/2021

Jeff K.

5/19/2021

The directions for determining the amperage across the blue wire does not apply to any brake controller that requires resistance (a load) to function. Example: Curt Triflex requires an electrical load be sensed before the controller will send a signal in the blue wire (signal = power) . A simple 12V test light shining brightly is a suitable indicator of signal.

Show All (24) Replies

Hide Replies

on Trailer Brakes

Videos

for Trailer Brakes

Help Articles

for Trailer Brakes

Expert Answers

for Trailer Brakes

Assuming that when you tested the resistance of the brakes you were testing the two wires on each magnet and getting 2.0 and 2.8 ohms the magnets on your trailer are not working correctly and will need to be replaced. For 7" brakes you should…

view full answer...Since the trailer was off of the ground it would not take much voltage to stop the wheels from spinning so they may be getting power but they may not be getting enough power due to a short or wiring issue. But 9 times out of 10 weak trailer brakes…

view full answer...You can indeed test a trailer's electric drum brakes by directly applying +12V power from a fully-charged battery. You can apply this power to the hot contact on the trailer's plug (see photo please) or to an individual brake assembly's…

view full answer...It is normal to have continuity between the brake(blue) wire and ground(white) wire. The electric trailer brake is an electromagnet when it has power it attracts to the steel inside the hub/drum. If you are having issues with your trailer brakes…

view full answer...I would check the magnets for wear before going on to test them with a meter. If the magnets show abnormal wear or if you can see the windings beginning to show through the friction surface of the magnet then they will need to be replaced. To further…

view full answer...Hi Roger! I contacted Dexter with your axle information and you will need the #25580 inner bearing and #14125A outer bearing. If you want the races as well, you will need the #25520 and #14276 respectively. The seal will be the Double Lip -…

view full answer...Are there any visible signs of wear on the magnets like exposed windings then that would indicate they need replacing. Magnets can go bad without showing visible signs of wear though. To see how to troubleshoot them check out the help article I…

view full answer...All the brake controller needs to sense a trailer connection so that you can test it is a slight amperage draw on the output circuit. For that you can use a circuit tester like the part #PTW2993 with one pin grounded and the other on the output pin.…

view full answer...If one set of brake assemblies is on the wrong side of the axle, it will lead to diminished braking performance and premature brake wear. Is it possible that the axle was removed at one time and reinstalled incorrectly? If you look at the photo I…

view full answer...The overload warning you are seeing indicates that the P3, #90195, detects an excessive current overload condition during operation. This means that there is most likely a short in the brake output wire. The P3 has diagnostic troubleshooting…

view full answer...It depends on what the brake controller output is set to. If you have the brake controller set to the maximum then there should be about 12 volts at the brake magnets. To see if the brake magnets are drawing the correct power set the brake controller…

view full answer...There are many things that can affect the voltage on the brake output wire from your brake controller to your trailer brakes such as the power setting on your brake controller, how you are testing the wire and if you are testing it with the brakes or…

view full answer...Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"In these days of customer "no service" I am usually disapointed when doing business with people I don't know. It was refreshing doing business with you. I'm impressed!"

Dallas S.

9/12/2025

I have a 6 month old flatbed trailer with 4 20” brakes. A rodent chewed one brake wire at the wheel. I fixed the wire and now when connected to my 2022 Ford F450 with factory brake controller, it shows trailer disconnected when manually activated. Then it says there is a wiring default. All other trailer light working fine. I inspected all the wiring for any signs of damage and it all looks like new with no damage. I measured the the resistance at both brakes individually and the both showed 3.4 ohms each. Then I measured the entire brake system resistance at the connector and it showed 4 ohms. I have a stacker trailer with 3 axels and 12” brakes. The resistance at the connector reads 9 ohms. I connected that trailer to the truck to verify the problem isn’t within the truck and it worked fine. Is the 4 ohms for the total system correct or does this indicate a bad magnet or wire somewhere?