To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

This is one of our favorite brake controllers, with flawless braking and a tiny dash knob that looks like it came straight from the factory. Its unique off-roading mode helps you handle rough conditions, so get out there and get towing.

Features:

Specs:

The off-road mode is a unique feature of the Redarc Tow-Pro Elite. In this mode, the brake controller will apply your trailer's brakes with a preset amount of power, independent of what your tow vehicle is doing. This is ideal for off-roading or challenging conditions. Set the power low if you're towing through sand or mud so that the trailer doesn't stop with too much force and act as an anchor. If navigating a steep descent, set the power to a higher level to ensure that the trailer doesn't push against the tow vehicle.

To activate the off-road mode, rotate the knob counterclockwise and apply your vehicle's brakes. Push down on the knob twice (2 times within 1 second) and release the brakes. The knob will turn green to let you know that the mode has been activated.

Use the knob to set the braking output -- the maximum amount of power that will be applied to your trailer's brakes. To get more power output, rotate the knob clockwise toward 10. To decrease the power output, rotate it counterclockwise toward 0.

When you apply the tow vehicle's brakes, the knob will change from blue to red to signal that the trailer brakes are being activated. The higher the braking power output, the deeper the red that you will see.

To engage manual override, simply press the control knob. This will activate the trailer's brakes and brake lights independent of your tow vehicle, great for stopping sway or controlling your trailer's momentum in an emergency.

When you are calibrating the brake controller for the first time, the LED lights will signal your progress.

You'll start by braking 20 times or so to let the unit learn its orientation and the direction of travel. You don't need to have a trailer connected for it to calibrate; the only difference is that the knob won't illuminate at all. If your trailer is connected, the LED light will flash green/blue as it calibrates. When the display turns solid blue, initial calibration is complete.

Once done, the unit will remain calibrated. If recalibration is required, it will happen automatically and without LED indication.

The Tow-Pro Elite has almost no mounting restrictions. It comes in 2 pieces: the main unit and the control knob. The main unit can be mounted out of sight and out of the way. You don't have to worry about dinging your knee on a bulky brake controller or interfering with your vehicle's airbags.

The control knob can be installed in any convenient spot that's easy for you to see and access. This can be a blank switch panel, an open spot on your center console, or wherever there's space on your dashboard. A universal mounting panel is included to ensure a clean, from-the-factory look. Custom-fit panels are available for certain vehicles as well. Before you do any drilling, be sure there's enough clearance behind the dash for the entire knob to install!

Once you've decided where you want to put the control knob, you'll need to find a good place to install the main unit. Your only restriction is the 3' cable connecting the main unit and the control knob. Securely mount the box using screws, double-sided tape, or zip-ties (not included). A mounting kit (RE67FR - sold separately) is also available for the Tow-Pro Elite. Do not attach the module to wiring or cables that can shift as you drive!

Then plug the custom-fit harness right into your vehicle and the brake controller and you're done!

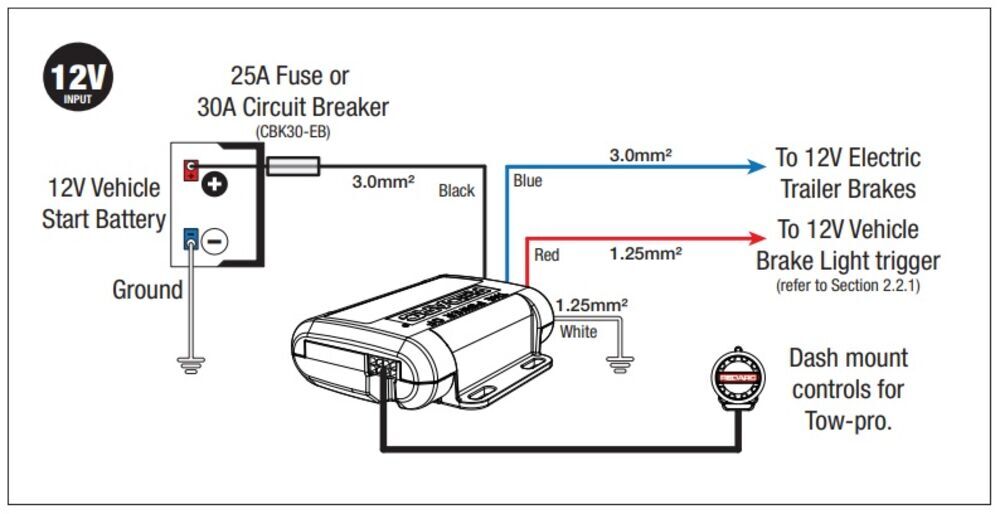

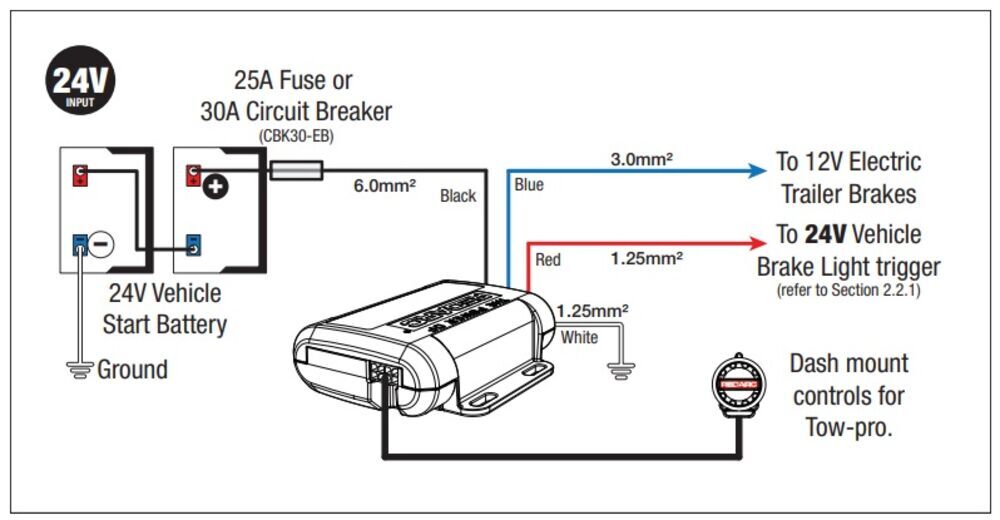

If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake-control installation kit (ETBC7 - sold separately). A 30-amp circuit breaker kit (331-CBK30-EB - sold separately) may also be required for installation.

For assistance in properly wiring the Tow-Pro Elite, please refer to the diagrams below:

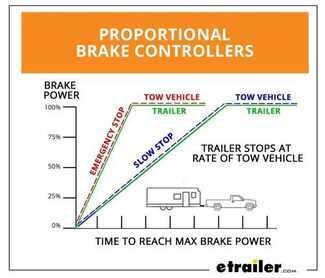

Proportional braking means that your trailer brakes mimic your tow vehicle's brakes. If you slam on the brakes in your vehicle, your trailer brakes will activate with the same intensity; if you brake lightly, your trailer brakes lightly too. The trailer's braking is in proportion to your vehicle's braking. This saves wear and tear on the tires and the brakes on both your vehicle and trailer.

The Tow-Pro Elite uses an internal 3-axis accelerometer to sense how your vehicle is braking so it can send the right amount of braking power to your trailer. It measures the inertia of your tow vehicle and activates the trailer's brakes to slow at the same rate. The result is uniform braking across your towing setup. No push-pull action - just smooth, proportional braking every time.

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Hi there Chevrolet owners, and your 2021 Chevrolet Colorado. We're going to be taking a look at and showing you how to install redarc's trailer brake controller. This brake controller has all the features of a premium proportional brake controller but doesn't have the giant mess underneath your dash with your typical brake controllers. You've got a large control module box and everything's inside that box there and you mount it here on the lower parts of your dash. And I'm a pretty tall guy. When I'm getting in, in and out of the vehicle my knees often bump on those.

It messes with my settings and I'm afraid that sometimes I might bump it and damage the dash here from where it's mounted. With the radar system the control module with the inertia sensor and that has all kind of the magic in it on how a brake controller works can be mounted anywhere inside the vehicle. We we're able to hide it behind our dash here, so there's nothing big here, sticking out just the input control knob here, which allows us to adjust the settings for our brake controllers. So you can see it as a much smaller footprint and it looks so much cleaner. This is almost like a factory-style look to it.

What we can see here that it's blue and if we we're to press in on the knob you can see that it turns red showing the amount of output that it's putting out. We can adjust the knob down. You can see that it gets closer to blue the less power it sends out with blue we're at zero being no output, red being maximum output. This is our sensitivity adjustment here. It is a proportional brake controller which means the harder we press the pedal here on our vehicle, the harder it will apply the brakes on our trailer behind us.

This brake controller also has user control mode which is something similar to time delay. It's their own style and it's mainly designed for our off-road applications. Because in a proportional mode, it uses an inertia sensor inside of the control module to detect the movement of the vehicle. So when we hit the brakes in this vehicle, it detects that inertia that we're slowing down and it uses that information to apply the brakes appropriately to match our vehicle. In user control mode it just applies the brakes after a certain given amount of time to whatever the value is you have it set here.

The reason that's good for off-roading is if we hit the brakes in our vehicle here, and we slide it's not going to detect really any inertia because we're not slowing down. We just keep on going. So it's not going to apply the brakes in the back very hard. In user control mode doesn't care about the inertia. It's just going to do it after a given amount of time. So that way, when we hit the brakes it is going to regardless send it back to the brakes on our trailer. So even if we're sliding here we're going to get the additional stopping power from our trailer to help us come to a safe stop in those muddy off-road conditions. To get into that other mode, you'll simply press down on the pedal and double tap it to make it turn green and we can double tap it there to bring it back. I usually turn it to zero. It seems to work a little better if you're at zero cause that way it's not going to be applying anything to your brakes at the back when you have it turned all the way down when switching boats. We'll begin our installation by locating our factory wires. They're located underneath this kick panel here. So we'll just take our floor mat out of the way. And then this panel here just pops off and kind of comes rearward and then up a little bit. So to remove it, it's easiest if you use your trim panel tool we're going to first get behind the weatherstripping here. And then we can get behind the panel. Once we get behind the weatherstripping and we're just going to work our way down and just kind of popping it off along the way. All the way down until we get to the end of the panel. We can just slide the panel off and set it aside. And this is where you're going to find your blunt-cut wires. They likely do have a piece of electrical tape that wraps around them. So they're going to be a little bit closer. I already pulled that tape off but you're usually going to just see them kind of like this. And you're looking for the little blunt cut ends there. You may also need to take a little razor knife to trim off some of that tape so you can separate them out so we can work with them. So now that we've got these separated, we can go ahead and figure out where we're going to put our module. Cause this was the first thing we needed to do is locate our wires. Our customer previously tried to install a brake controller. And so he already has some preexisting holes in the dash. And we're going to try to reuse some of those pre-existing holes for the Redarc here. Cause he was a bit unsuccessful with the installation. So this is where the customer was trying to mount them, so we're going to try to reuse this to salvage this panel. So we're going to remove this panel so we can do that as well. On the bottom there's going to be two screws that hold it on and we'll use a seven millimeter socket to remove those. And it's a pretty good idea to remove this anyway even if you're doing this at home because you're going to need to find a mounting location for your switch and getting a good look back here will likely reveal some areas where you could put it. Now we've got the two screws out. This panel actually just pulls it off from there. So you just get your fingers behind the lip here. Just kind of pull it towards you and then just kinda work your fingers are on the other side and do the same thing, pulling it towards you. Now we've got that pulled off. We've got a couple of electrical connectors that we'll need to remove to remove these first. We're going to take a flat-bladed screwdriver or a little pick and pop out the lock tab here in the center. Then we can press in on the release tab and pull out the connector. We'll do the same thing with the connector over here on the side. It's just on the side instead of angled down pop that up and then you can press it on the release tab and slide it off. You could release down here at the bottom that just slides off right there. If it sticks on you, there is a little tab right here and you just kind of put your screwdriver and then just put a little bit of downward pressure on that center tab. if it doesn't just slide off that'll help release it from the, the panel here. So now that we've got this out of our way you can take a look at there where we're going to mount it. It's a good idea to kind of hold this up here and see where you have room. Cause the switch that comes with the red arc is a fairly deep switch. This is our switch here. So we can see this is the button that it would stick out beyond our, where we mount it but all this black part here is going to stick out behind it. So you want to look to see where you can get the switch mounted. And if we want to reusing the pre-existing hole here as we looked over there we can see that there's kind of some stuff in this location. We're likely going to need to cut out this section here on ahead and marked it where we're going to be cutting to make enough room for this switch. But if you we're putting, if I was doing this at home I would probably put it on this side. Cause there's a nice big opening here where it's just plastic. You can see down in this slot here that there's nothing behind this plastic. So you could easily take this panel here and you could cut your hole here for your switch and then cut out a hole here in this panel right behind it, and you'd have plenty of room to easily working and get to everything doing that. So that's where I would probably have mounted it but we're going to be doing here. So in order to get it mounted over there I'm going to be removing this panel and I'm going to be trimming that off so we can get we're going to remove these bolts here and go ahead and do that. If you are going to be installing it at the same place we are to remove this panel you use a 10 millimeter socket. So now we're going to take off this section here so we can get our switch to fit. You can do this however you like, depending on the tool you've got. We're just going to use some snips to cut it because it's a fairly thin piece of metal. Next we're going to go ahead and mount our module to this panel here. I went ahead and just took it the module here and stuck it up there. The I removed this panel just to see where it would fit and it's not going to fit on the front side here like this. But I went ahead and sat it on here and marked out the slots there because we're at will fit is on the backside. We're going to end up mounting it like this with some zip ties. Once we get the panel installed back up in there. We can go ahead and get these holes drilled out now, if you left your panel in cause you didn't need to modify this here. You could drill it right in the car. But since we got this out of the car we're going to go take it over to the rice and get these drilled out. Since we're just going to be battling this with zip ties for, and use a quarter inch drill bit but it doesn't have to be exact. You just need to be able to fit your zip tie through it. You can wrap this up by taking some zip ties. If you need some zip ties, you can get some here at etrailer and we're just going to be running them through the module, through the holes that we drilled, back through. to our module once again. And then we'll reattach it to that zip tie. It's like, it's going to be just a little bit too short but that's no big deal if it is too short you can take a second zip tie. You can slide it on one side, slide it on the other. So extend that out to make it longer. Going to do the same thing in the other old hole over here on this side. Once we get all of our zip ties secured, we can snip off any of the excess. And we're now ready to reinstall this panel back into the car. So now we're just going to set our panel back into place. I'm going to hold off on putting the hardware back in cause we might need to take it down but I like having it where it's going to be hanging out. So I know where I'm going to route my wires and how long to route them to. So we can now start by getting the harness routed over to those blunt, cut wires. That's going to be this harness here. So it was like, we're gonna need pretty much every bit of the wire that we've got here in order to get it over there to start routing the wires towards the blunt cut ones and then we'll make the connections when we get them routed over there. So now we can go ahead and start making our connections. You can get the bug connectors here at each trailer. You've got various sizes here. We're going to be using the yellow ones for the thicker wires in the blue for our thinner wires. The wires here that come on are come with the radar, the harness, is going to have a blue, red, white and a black. We're going to start by hooking up the power wire which is the black wire on our harness that comes with our brake controller. And you can see it's labeled there. We're just going to slide that off. They come pre-stripped we'll slide a butt connector on there and then we're going to crimp this down. And then this is going to connect to the power wire on our vehicle down here. And that's going to be the red wire with the green strip. So we can just pull those of there cut them off, strip it back. However you needed to do it, to get this wire exposed. Slide it in, to the other end of our butt connector here and then crimp it down. Once we got this crimped down we're just going to repeat this with the remaining wires getting those connected to our factory ones here. So after getting our power wire connected we then moved on to the blue wire from our harness. That's going to connect to the blue wire on our truck here. Next is, and this is our breakout put from the controller. Next is the white wire. That's on our harness that's ground. That's going to connect to the black wire on our truck. And the lastly is the red wire on our harness. That's the brake input signal from our vehicle and that's going to be the white wire with the blue Stripe over on the vehicle here. So we got those connected. We can take a zip tie and clean up this wiring. We're just going to zip tie it to this factory harness here, keep everything nice and neat. So now he can go ahead and plug this into our module and sees, you can just slide this panel off. So we're just going to slide that off. Barge it in there. You can go ahead and temporarily set this back into place and now we're going get our switch mounted up into our other panel. So now there's a lot of different ways you can mount this switch. You could just drill out the hole here for the switch to pass through and secure it with the nut. But it, you also get a blank space insert here. And this is nice if you, maybe have like a blank button you're wanting to replace or something, or if you have something you want to cover up in your panel, like we may didn't make the cleanest cut in your hole there. You can use this to snap this in. This is what we're going to be using, that it comes with to help hide all of this. So I've marked this out to just find the area where you're going to mount that. The, and I would have probably put mine over on this side but it'll work fine over here. So we're going to go ahead and just cut this out now and we're going to be using a step bit so we can slowly step that up to make sure we get a good fit for our piece. So I've gone ahead and drilled it out. And the stiff that we use tops out right at about seven eighths of an inch and this seems to be a pretty tight fit which is what we're looking for. We want it to be snug when it gets in there. So we can go ahead and just pop this all the way in. If you can't get it to quite go all the way she can see it's got some years there. We may need to take out just a little bit more material in order to get it to go which there's what it looks like we're going to need to do. So after MRI to get just a little bit more in order to get it to fully seat up in here we did have to drill it out to about an inch. So now we can go ahead and install our switch. If you chose not to use the insert like we did after you drill your hole, you would put this little sticker on the panel and then slide your switch through and attach it. If you use this piece here, you don't need the the little sticker. We'll then take our switch. It's going to slide in with kind of a, almost like a release tab. It's not, but it kind of looks like one like those towards the bottom we'll then push through our switch here no wrestle. And then we can secure it with the clear plastic nut And you want to just be gentle when tightening down, this is a plastic nut. It does need to be tight enough to have the switch secured enough for a button to get inserted but we don't want to go really tight because again it's just plastic. It can be pretty easy to damage that nut. That's about as tight as I feel comfortable with it being a plastic nut. So we've got that on there. We're going to take our button now. And I like to turn the switch all the way counter-clockwise counter-clockwise is going to have it set toward zero, is at the top. So full counterclockwise turn, put zero at the top there and then, just push your nylon. And there we go. We got 0 10 0. If you don't like the positioning it does just pull right off. You can move it over a notch if you want it to. That looks pretty good though, because pop for zero to three at the top in one direction, tend to be at the top in the other. You also want to check does your button can press and you hear an audible click. If you don't hear a click then your nuts slightly not tighten down far enough yet to pull your switch all the way through. You might need to snug it down just a little bit more. If you're going to click just like this your switches installed, we can go ahead and route our wiring from our switch here to our module and get those probably together. We'll take the white end of our switch harness. This is going to plug into our switch, click, snap those two together, then the other end of our harness we're going to route over to our module. So when we got to the box this panel is still little bit loose. So we can just slide this off of here, take our switch and then click that into place. We'll then reinsert our panel here. And this is where you can kind of check the routing of your switch wires, make sure everything looks okay there. You can might be able to push it back up in there. So at this point we can sort of test it out. We do want to get the bolts back in here, cause our module we can't have our module all loose and moving around the proportional part of the system won't be able to work if the module is not secure. So we're just going to get these ones in and then tighten these down. Careful with your wiring, don't pinch any wires. So now we'll take this panel. We can also re-install it as well. Make sure you slide your hood latch cable back into place. It just slides on and clicks in just like that. And then also make sure you plugged in any electrical connectors that you may have had to disconnect. And our panels just clicked together and we can see there. The switch is breathing blue, which means it's powered up. It's not going to do anything else right now because the system needs to be calibrated. In order to calibrate it, you just drive your vehicle like normal. Now when you're driving and if you don't have a trailer connected it still will calibrate itself but you won't really get any feedback from your system here. What telling you whether or not it's calibrated finished calibration. If you plug in a trailer and drive around you'll get some feedback from the switch here. It will flash between blue and green. And you'll see that the intervals that it flashes between blue and green will get faster as it gets closer to being calibrated. And once it's calibrated, it should go blue for you. So we went ahead and drove the vehicle to get it all calibrated. It did take about 10, start to stop cycles for this one to get calibrated. It is going to vary and it can take up to 20 start to stop cycles. But once it's done, you'll see here at solid blue we have a test box connected, which stimulates a trailer. If you don't have a test box. You can just plug your trailer in because you're not going to get feedback without something connecting to your seven way back there. And if we look at the top right display that's going to show the voltage, going to the trailer brakes on our test box. Here we can increase or decrease that for the adjustment that we need for our particular trailer. And that completes our installation of Redarc's trailer brake controller on our 2021 Chevrolet, Colorado..

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.