Trailer Wiring Diagrams (for Non-Electricians)

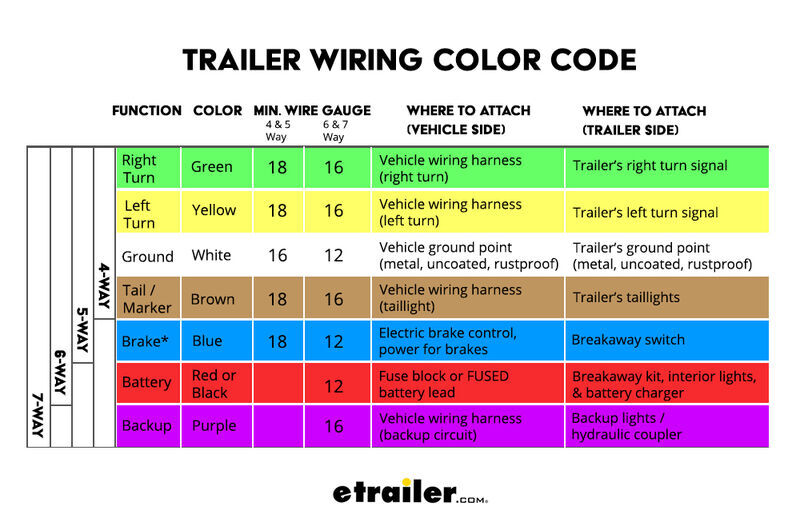

Trailer Wiring Diagrams

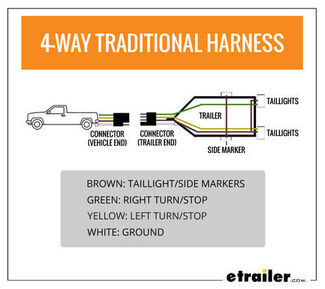

Trailer Wiring Connectors

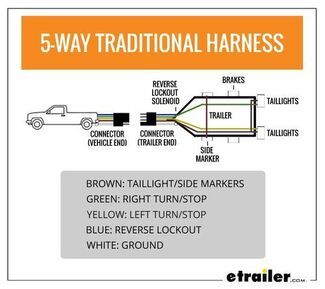

5-Way Connectors

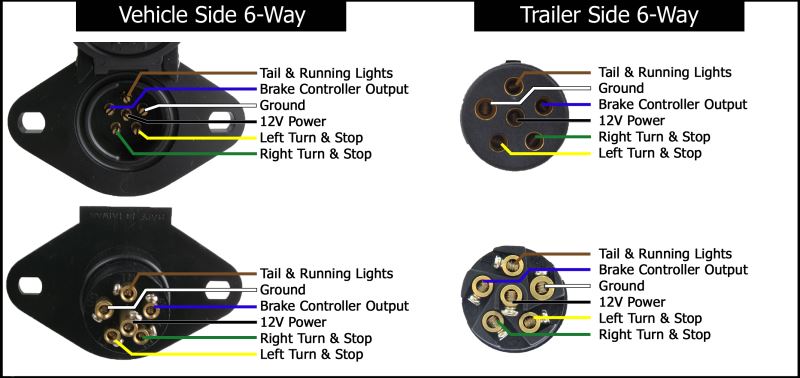

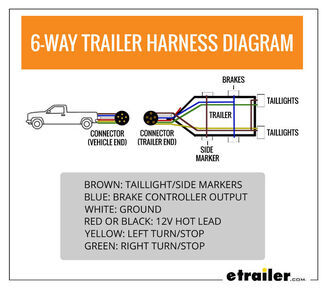

6-Way Connectors

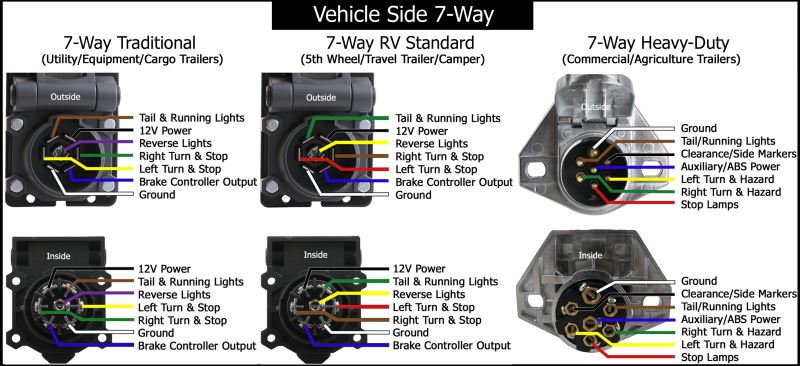

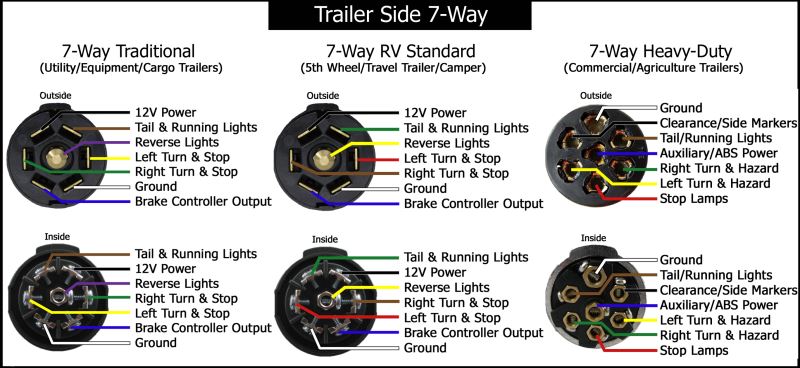

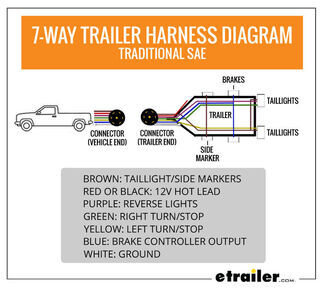

7-Way Connectors

Mounting Your Trailer Wiring Harness

Trailer Wiring Adapters

Troubleshoot Your Trailer Wiring

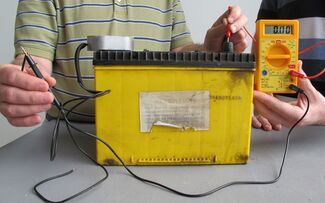

Problem: There is no signal going into the box, meaning something is incorrect on the vehicle. Solution: Solve the problem by checking for blown fuses and then check the installation points. Use a circuit tester to check that the correct wires are tapped into, the wiring harness connectors are plugged into the correct vehicle connectors, and check that connectors are plugged in all the way. Problem: If a signal is going in and coming out on the appropriate wires, then there is a problem with the trailer wiring. Solution: Solve the problem by inspecting the wiring on the trailer to make sure all of the connections are correct and ground wires are connected properly. Most likely, the ground wire on the trailer is not secured properly. A trailer wiring system is grounded to the frame near the coupler and each light also needs to be grounded. If there is not a white ground wire coming out of a trailer light, then the light is grounded through its mounting studs. Too much paint, dirt, or rust can cause bad grounds, so make sure the ground is secured to the bare metal frame. Also look for pinched or cut wires; these are often found when wires are routed above suspension components or behind tail lights. Problem: If a signal is going into the box and not coming out or a signal is going into the box and coming out on the wrong wires the ground on the vehicle may not be connected properly. If the white ground wire is not installed properly on the vehicle, then the green and yellow wires will not carry signal coming out of the box. Solution: Solve the problem by checking to make sure the ground wire is installed properly on the vehicle. To make sure you have a suitable ground, first connect the circuit tester's ground wire to the same location as the ground wire on the wiring harness. Then test the signal going into the converter or modulite box. If there is no signal, connect the circuit tester to another grounding location such as the exhaust pipe. If a signal is present, the grounding location for the wiring harness is bad, and a new location needs to be found. On a few vehicles, the frame and body components are not grounded. In these rare instances, look for a ground wire coming out of the license plate light.

Issue: Converter Shorting Out

Too many lights on the trailer. Each incandescent tail light draws about 2 amps and side marker lights typically draw about 0.5 amps each. Most converters allow up to 4 amps to pass through them. A standard converter cannot have any more than 1 tail light on each side. Water. Trailer connectors get wet, causing too many amps to be pulled through the converter. Water can unite all 4 wires on the trailer connector causing it to draw too many amps. This often happens when a boat trailer is backed into water with the trailer wiring still connected to the vehicle. To solve the problem of connections getting wet, always disconnect the trailer connections before backing into the water. Also, covers can help prevent water from getting into trailer connectors when it rains or when a vehicle is taken through the car wash. Bare wires touch each other or the trailer frame. This causes too many amps to be pulled through the converter box. The coating on trailer wires can wear thin, often at the connection to the trailer's tail light or where the wires pass over the trailer suspension. If wires are hung too loosely, they can get pinched and smashed between the trailer frame and suspension U-bolts. To solve the problem, inspect the trailer wires and replace any that are damaged or frayed.

Issue: Weak Ground

The connector on the vehicle should have a ground wire secured tightly to a clean surface on the frame. A wire attached to the body or a surface with undercoating or rust can cause a ground problem. The connector on the trailer should have a wire from the connector secured tightly to a clean surface on the trailer. Each tail lamp assembly at the back of the trailer also must be grounded. This is done in one of two ways. The first is by a separate wire coming from the back of each tail lamp assembly being secured to the frame. The second, and most popular, ground is achieved through the bolts of the tail lamp assembly. In this case, the lamp housing must be attached to the frame of the trailer. If the lights are mounted on wood or PVC material, the light will not receive ground. The last possibility to explore is in the trailer design. If the trailer has a tilting bed, it is possible the ground is not passing through the pivot point, resulting in a poor ground. The solution to this is to route a ground wire from the connector at the front of the trailer to each lamp assembly at the back of the trailer, bypassing this pivot point.

How to Wire your Car or Truck to Pull a Trailer

T-One Connector

Custom Hardwire Kit

Standard 4-Pole Wiring Harness - For use with vehicles that have adequate power and standard wiring system, these simply connect into existing wires on the vehicle and have a 4-pole flat connector to attach a trailer. Converter - For use with vehicles that have separate turn and brake light wires. Some vehicles send only one signal per wire, creating what is called a 3-wire system: one wire for the left turn, one wire for the right turn, and one wire for the brake signal (common on vehicles with amber turn signals). A converter will reduce it to a standard 2-wire system needed for wiring a trailer. There are still additional wires for the running lights and for the ground. Any vehicle with amber turn signals will need a converter. However, there are some vehicles with all-red tail lights that can also require a converter. A wiring harness with a converter has a black box built in it. Five wires go into the box, and only 4 come out. The converter transfers the brake signal on the vehicle into the left and right turn signals for the trailer wiring system. Modulite or Powered Converter - Used with vehicles that do not provide enough electrical power to handle the additional strain of powering trailer lights, the Modulite or powered system draws power directly from the battery but still connects to the vehicle's wiring system to determine when to power the lights on the trailer. If there are too many lights on the trailer for the vehicle's electrical system to provide adequate power, use a modulite or powered converter. A modulite installs the same way as a standard converter except an extra wire must be run to the battery. Instead of drawing power from the vehicle wiring system, a modulite draws power directly from the vehicle battery. This is safer because the extra amps to power the trailer are no longer going through the expensive electrical components of the vehicle. More vehicles are using thinner gauge wire and require a modulite, regardless of how many lights are on the trailer, simply to protect their wiring system.

Don B.

10/17/2025

Trailer and lights have working fine. Now all of a sudden when I back up my car trailer I notice that I'm pushing the trailer backwards. Brakes are applied. Pulling trailer forward seems to be ok

Derrick K.

10/19/2025

Larry

9/7/2025

2003 silverado with factory trailer wiring harness. The yellow left turn/ brake wire has no power. All other wires ok. It's not the connector because I bared the wire to test. As far as I know there is no fuse for the one wire. I'm lost as to why it would go dead when nothing in factory wiring has been altered

Robin H.

9/9/2025

Larry

9/9/2025

Jason S.

8/11/2025

I can't figure out the running lights on my brother's car trailer. When I took the 7 point plug apart there is a white wire with a brown stripe on it that's for the running lights for the trailer. I'm not sure where the wire is supposed to go. Any tips or whatever you have will be helpful.

Jesse M.

8/12/2025

Jason S.

8/12/2025

Jim D.

8/8/2025

I am wanting to install and electric tongue jack to my new box trailer with electric brakes and want an independent power source for it. It appears I am using the truck as a ground as I have 5 ground wires attached to the plug ground. I also want my interior lights to run both when it is plugged into the truck and when it is not. So, could I add a chassis ground on the trailer off the battery for the jack, and then add a jumper to the lights so they operate off both the battery and the truck when the light circuit is on? There is a wall switch in the trailer that controls the lights.

Jesse M.

8/8/2025

Roel F.

5/18/2025

Good afternoon this question is directed to electrical gurus that like to Tinker. I’m trying to hook up on airhorn to my seven trailer connection. I’ll be using a 12 V always closed solenoid, but my question is if I can act it using my brake controller toggle inside the cab.? Will the horn sound every time I press on my brakes once the 17 trailer connection has been established or will it only be actuate using the brake controller?

Jameson C.

5/20/2025

Roel F.

5/21/2025

Jameson C.

5/21/2025

Tom T.

5/16/2025

I purchased a brand new camper and before I left the dealership I checked to make sure all lights and signals were working which they was. I get 200 yards down the road and I see heavy white smoke coming from under the truck. I stop and inspect the issue which was the wiring harness had melted in 3 areas from the back of the plug at the bumper to the oem connector. I've never seen it heard of this.

Jesse M.

5/20/2025

Fred J.

2/28/2025

I have a Jeep 2020 Wrangler with a modulite for added power but doesn’t seem to have enough power for trailer lights when running lights are on. I have replaced wiring to plug on Jeep as Salt/ water get in connector over winter.4- wire flat . I have a separate battery in the enclosed bike trailer for charging sport vehicles and interior lights. This has dc battery charger I plug in to ac when available. Is it possible to wire this additional battery to my running lights using a relay?

Kate F.

2/28/2025

Kenny

1/17/2025

This diagram claims it's for non-electricians. I am an electrician and sometimes the non-electrician diagrams are terrible. This is probably the best trailer wiring diagram I've ever seen! Thanks and keep up the great work!

Jerred H.

1/17/2025

Mary P.

12/30/2024

Hello, I am planning to relocate my batteries from the front tongue of my trailer to the back, since I'm going from wet lead acid to agm. I have a 7 pin and everything is currently connected and working fine with the batteries up front. To move the batteries back, do I just need to get a longer red wire and replace the current one so it reaches the new location? And if I'm moving the batteries back by about 20 feet, do I need to increase the wire gauge? How do I calculate what gauge wire I need? The length would be around 20 feet, and it's connected to two 100Ahr AGM 12v batteries. I want the red wire to charge the batteries while hooked up to the truck and driving (which it does now). But I don't know what the current is, coming from the truck. And do I need a fuse, and if so, what size?

Benjamin

10/24/2024

Super quick here. On my new trailer all new lights my truck has a 5 plug well it’s a 7 but only 4 tabs and the center for backups. Without cutting a bunch of new wires, I have a 5 flat to a round 7 adapter to my truck. The 5 flat has the extra mine is blue wire. The new lights ,(pods) for my backups have just the red and black. I know that the blue wire has to hook to them in what way ? Do I run the red and black wires to the white and brown where does this blue hook? I have lost my self in this and normally I can fix anything, ( Country style ) !!

Kate F.

10/25/2024

John B.

11/25/2024

Kate F.

11/25/2024

Sue

10/24/2024

I have replaced tail lights on a trailer and have what appears to be a ground issue and I’m stuck in my retrofit. When the running lights are on, all lights work on high (braking illumination), when I use the turn signals the appropriate side (L/R) responds but blinks in opposite time from the tow vehicle blinkers. When I step on the brake the lights go out. Can anyone see an obvious issue here? What am I missing? I have a two horse bumper pull trailer that had the pre-LED era 4” round lights as the only rear indicator lights. After nearly getting rear ended with horses in the trailer I am replacing the rounds with 4” LEDs and adding a strip light to each side as well for added visibility. Help appreciated!

Jerred H.

10/24/2024

Lori

10/15/2024

I would appreciate any guidance. We have a 2023 Riverstone 39RKFB. The back right-side markers are on and we are plugged into shore power. We have cleaned the 7 pin plug (it's dry with no corrosion) and disconnected shore power and battery but nothing works. Can you recommend a solution?

Kevin C.

9/30/2024

Lou

9/30/2024

Kevin C.

9/30/2024

John B.

11/25/2024

Kevin C.

11/25/2024

Isaac H.

9/26/2024

2012 Sonoma 20 ft Trailer My brakes do not release while trailer is hooked up either by battery or towing vehicle. If I unplug everything including battery breaks release Cannot figure out what my issue is?

Jameson C.

9/26/2024

John B.

11/25/2024

Jameson C.

11/25/2024

Mike S.

9/22/2024

I have a new boat trailer with a 7 pin. I have no brake lights. I had brake lights etc when I first got it 1 month ago. I found many bad slices and worn wires on the trailer. I started with a new 7 Pin retired with new wire from front to back. All other functions work. Both turn lights work. I then figured out the there is no power/signal to the plug on the truck side. Yet there is still turn signal there. They are supposed to be on the same circuit. I replaced the truck receptacle thinking that was the culprit. No luck.. I have checked the 2 fuses under the hood labeled turn/brake. Both 10 amp fuses were fine on the ohm meter. Truck is 1999 Silverado I have had since new. I have not spliced up any of the wires. It all original. I have used this to pull my old boat with a flat 4 connectors for 25 years. Never an issue. I am going to check the back of the new trailer pin receptacle to see if there is power there and then follow the wires up to the main junction box on the frame. I have already pulled each of these wire bundles and checked for bad pins etc and they are all appear perfect. I have seen some pictures on line of this junction area being badly corroded etc. Mine is near mint. Not sure where to go from there. Any advice? I’ve scoured the webs looking for ideas. Thanks

Mike S.

9/22/2024

Jameson C.

9/23/2024

Jimmy L.

8/27/2024

My inverter is shorting out. A spark comes from inside the box from a reostat the size of a D battery. It's wet to the touch. But I don't think it is water. I have checked short ground on every plug and wire coming in to the breakers. I'm stumped! Thanks

Jameson C.

8/27/2024

Phil M.

8/25/2024

I tow an RV Trailer with my Subaru Ascent using a Subaru-installed 7-pin connector. I also use a brake controller connected to the wiring harness that accesses the 7-pin. After some challenges, our Subaru dealer repaired the 7-pin connection. My RV trailer lacks reverse lights. At this time, turn signals, brake lights and brake controller work great, but there's a lack of running lights. Would that indicate the #3 pin is not wired correctly or would it indicate a grounding problem. Trying to get back on the road for some fall camping!

Kyle S.

8/26/2024

Philm

8/26/2024

Kyle S.

8/26/2024

Hil M.

8/20/2024

On 7-pin 2020 Orangeline utility trailer, lights won't work (except the license plate lights) when truck (aftermarket 7-pin) has headlights or running lights turned on. NO headlights, all turn signals and brake lights are fine. Horse trailer that truck pulls is fine. This just a brown pin connection thing? How to test there's even power getting to that running light pin on trailer? Thanks.

Bryce D.

8/20/2024

Dennis D.

8/12/2024

On my 2012 three horse slant trailer, a mouse chewed the white and black wires that connect to my interior lights. How do I reconnect them so I can get them working again?

Bryce D.

8/13/2024

Dennis D.

8/13/2024

Bryce D.

8/14/2024

John B.

11/25/2024

Bryce D.

11/25/2024

Gordong

8/3/2024

Good article however there is no coverage of how to wire in a trailer brake breakaway switch.

Jaysonb

7/28/2024

Great resource, thank you! Just curious though - I have a 2022 Toyota Tacoma Limited with the factory installed towing package. I just installed a Redarc brake controller following your eTrailer's recommendation and the install video was very helpful. My question is: Is there anything different about Toyota's 7-pin? I just rewired my equipment trailer and want to make sure I'm not missing anything. At first glance the pin-out from the factory receptacle on the truck doesn't look the same as what everyone says is standard, but maybe that's just my tired eyes. Thank you.

Jon G.

7/29/2024

Jaysonb

7/29/2024

Jon G.

7/29/2024

Matthew

7/22/2024

i have a 5 pin connector for a rv and the blue wire i was told is back up. Ive run that wire to the reverse lights on my rv and when i put it in reverse I get nothing. The reverse light has a red wire and a ground. the other lights have the typical signal brake and marker lights. how do i get the reverse lights to work?

Bryce D.

7/22/2024

Bryce D.

7/22/2024

John B.

11/25/2024

Bryce D.

11/25/2024

Terry

7/1/2024

My rv lifepo4 (14.6v) batteries are back feeding to my truck and causing the trailer brake to error and not work; can't I just remove the positive connection in the system? isn't the 12V on the 7 pin just AUX and not used other than to power the breakaway box; can I / how can I remove the 12v connection that is backfeeding to the truck, I don't need that right?

Paul

7/13/2024

Martin

6/21/2024

I would like to say this is the most complete source of info I have ever seen Thanks

Kenneth

5/14/2024

The "E-Trailer" branded graphic called "7 Way RV Plug Wiring" is at odds with everything else on this page, and seemingly with other sources. I'm just looking to begin diagnosing a brake problem on my own trailer...

Moe

5/14/2024

My signal works good left side try right side all lights blinking even clearance lights

Joseph

4/21/2024

I have a 2001 GMC Sierra 3500HD with no factory installed trailer connection. How do I connect the red controller wire to the brake switch or other brake light cold wire? Thanks,

Jon G.

5/15/2024

Helpful Links

Jan M.

1/9/2024

I rewired my boat trailer per instructions, but no lights. Troubleshooting included rechecked ground (white) wire, used a volt meter to check the car 4-way connector, each light wire and even the bulb socket. All had power. Still no lights when I put the bulb in the socket. Any ideas? Thanks

Mike L.

1/9/2024

Jan M.

1/9/2024

Mike L.

1/10/2024

Phloridaphil

1/24/2024

Mike L.

1/24/2024

Jan

1/24/2024

Mike L.

1/24/2024

Chad

12/9/2023

Hello, I have a 1999 GMC digger Derrick utility truck and it has a round 6 pin plug on the truck side. The trailer I'm going to pull is a large 37' pole trailer and the trailer has a 7 pin round plug. I can't find an adapter anywhere and I think I have to build my own, need some help!

Chad

12/11/2023

Neil W.

11/12/2023

Awesome page. I’m trying to replace my 6-pin plug with a 7-pin on my gooseneck trailer. Brakes have worked great with an adapter in the past. When I look at the wiring in the 6-pin, the brake pin is not connected and there isn’t a blue wire. Just a black wire on the 12V center pin. I noticed the page said “Note: In some applications, the black battery power connection and the blue brake controller output connection are reversed.” I’m totally confused how the brakes have been working with the factory brake controller without the brake pin being used. Any help would be appreciated.

Jenny N.

11/17/2023

Neil W.

11/17/2023

Daulton R.

11/8/2023

Thank you for providing the guidance and instruction that you do. It is extremely helpful for a lot of people. The more I visit your site the more I want to come back for help, and purchase from you.

Jenny N.

11/16/2023

Daulton

11/17/2023

Jenny N.

11/17/2023

Daulton

11/18/2023

Ian

4/25/2024

Pj

10/26/2023

We bought a brand new 2023 dump trailer at auction. It was made in Mexico and does not have standard color-coded wiring. We have all lights and brakes, but when we turn on the headlights of the tow vehicle, the brakes on the trailer come on and stay on.

Mike L.

11/12/2023

Helpful Links

Char

10/21/2023

I have a 2008 Dodge Ram 1500, with an unplugged blue plug labelled "Electric Brake" under the dash, but only a 4-flat connector at the rear. What do I need in order to utilize the electric brakes on my trailer?

Nik C.

10/24/2023

Mike L.

11/9/2023

Char

5/8/2024

Mike L.

5/15/2024

Mike L.

11/9/2023

John M.

10/17/2023

I have purchased a used 1992 Bigfoot 17 travel trailer. When connected to my 2009 Dodge Nitro I get RT and LT lights working properly, as are the brake lights and flashing lights.. I do not get running lights working. My buddy connected with his 2015 Cherokee and we got the same result. I have replaced the 7 pin connector - thinking it was faulty - but the same situation exists. My buddy's Cherokee has factory installed trailer brake and when he pulled the trailer the brakes seemed to be working ok. The 12V trailer battery has not been connected through all of this testing. Your thoughts please. Thanks.....john

Mike L.

10/17/2023

Charles

10/10/2023

Hello, I just got a vintage 1988 mallard 28rks 5th wheel. When I got it all d.c. and 12 volt items worked. May have been on shore power I'm not sure. Anyway after trying to hook up the battery nothing worked not even a light. Checked converter all connections look correct. Followed out. Negative is a copper wire coming of Negative of panel going to bus then down into floor to frame. Positive I followed to crossover where it goes into the wall. Another black wire comes out of the wall and goes toward battery. From what I can tell, black Positive wire goes to 6 pin connector which goes to a box with 3 wires all black not hooked up and the ground wire on the connector is not attached at the screw. 1, is this the issue? 2. Can I connect all 3 wires with no issue. 3. Technically can't I hook all to positive as long as my negative goes to frame as needed. Thanks

Mike L.

10/11/2023

Beth

9/18/2023

I want to put a wireless backup camera on my travel trailer, wired into a rear marker light. However, I'm told this camera won't work if I'm pulling the trailer with my 2021 GMC Sierra, because of something called "Pulse wave modulation" causing the camera to not get enough voltage to work? Is there a solution or work-around for this issue?

Beth

9/19/2023

Mike L.

9/19/2023

Beth

9/20/2023

Murat

9/10/2023

Hello All. I need help with loosing power on my Prolite Plus S. After 3 months we went to a short trip and on our stop suddenly light went off inside the camper. It was connected to my Model 3 through Curtis bluetooth controller. When I check the car side power with a multimeter there was no power coming to 7pin connector( I learned that model 3 have electronic breakers it reset it self after sometime). Wait for 24 hours and connected the controller back to car and started to work. Then I connected to camper and loose the power again. I think there is short in the camper but I checked the all fuses and breakers they were all good. Please any idea helps…

Mike L.

9/14/2023

Kennys

8/21/2023

Can anybody tell me if the batt wire lead on a 7-pin can be used to keep a 12v Batt charged that is used to run aerators on my fish hauling trailer? Is there any amp output info available?

Mike L.

8/22/2023

Phil L.

8/9/2023

Where can I find yellow & brown & green & brown trailer wires together to rewire my utility trailer

Mike L.

8/10/2023

Craig V.

7/19/2023

Have a 2018 camper which is almost brand new used very little keeps blowing left turn signal fuse. Also have 2001 Hallmark trailer that blows the same fuse hard to believe 2 trailers have shorts on same circuit. Think it could be on the truck side?

Mike L.

8/2/2023

Russ

7/17/2023

OK so just bought an older RV and it has a 4 Pole round socket at the hitch, I have use of a small trailer with a 7 blade round plug. Question is is there an adapter available to plug the 7 into the 4 on the RV? The 7 blade was used on trailer to plug into a truck with an existing 7 blade at the hitch but trailer has no brake, back up light or 12v supply.

Russ

8/2/2023

Russell

6/29/2023

I have a 7 & a 4 pin connector on my 2020 rv my question is I have a hitch mounted storage box that needs lights and a reverse light I was thinking of using the 7 pin for storage box and 4 pin for boat lights, would there be a problem with that? Also what wire on the 7 pin is reverse light? Thanks

Heather A.

7/17/2023

Jose A.

6/25/2023

I have a 7 pin connector but the wires that were ran do not have a blue wire. Just green black brown yellow red. I hooked wires up with out the blue and the back tire on my trailer locks up?

Mike L.

7/15/2023

Marc

6/5/2023

Hello I have a 2012 Jayco X23b. I am having a problem with the right rear light assembly. Under normal conditions, the brake light and turn signal on the right side work as they should but when you turn on your marker lights for the entire trailer, the right rear light becomes extremely bright, will not show the brake light working or the turn signal. Just stay is extremely bright. Now if you turn the power off to the marker lights, it works like it should turn signal and brake light work together. it is not on the vehicle side I pull a boat trailer and a flatbed trailer as well and do not have that issue with either one of them. Any ideas.???

Mike L.

6/6/2023

Cory

1/13/2024

Marc

1/14/2024

Michael

4/27/2023

I purchased a Tekonsha T-one Wiring Harness With 4-pole Flat Trailer Connector for my 2017 Range Rover Sport, I tested it and it doesn't seem to receive any electricity. The fuse is ok. I hope someone can give me some advice.

Mike L.

4/27/2023

Helpful Links

Michael

4/27/2023

Michael

4/27/2023

Mike L.

4/27/2023

Derek

4/17/2023

Brakes not working on 5th wheel, 2012 Montana 3400rl brakes not working, use a 2013 chevy 2500hd truck. I hook up camper cable to truck all the lights work but while doing a brake test nothing no trailer brakes even slideing brake controler form low to highest nothing no change. truck does not even acknowledge trailer brake hookup. I changed truck plug first easy enough no change, could not find any bad wires under camper from brakes, check ground wires nothing I did just get new tires put on not sure if that could have done it, before I start spending more money for no change, I could use some advise on this problem..please.

Marcus

2/12/2023

I have a Tekonsha Primus IQ and the wires in my 2022 Tahoe are run but not in a connector. There is a wire labeled “to trailer” does this go to the input or output of the wiring harness?

Mike L.

2/15/2023

Phil

2/6/2023

Installing 4 wireless security cameras, 3 inside 1 outside on horse trailer. Should I tap into running lights for power or is there a better way to approach this?

Mike L.

2/8/2023

Mike L.

3/27/2023

Skyler R.

12/5/2022

I'm having trouble wiring in a new 7 pin plug on my pressure washer trailer. I only have 6 wires: Red White Black Yellow Green and Brown. When I hook the connector to my truck, one tail light comes on, no brake lights and turn blinkers on they all blink. Guess I need to know what the color codes are and if it could be a ground somewhere else. Thanks

Mike L.

12/5/2022

Helpful Links

Skyler R.

12/5/2022

Joe H.

12/4/2022

I have a 6x12 enclosed trailer that all the lights and signals work the way they should. When it's plugged into my 2018 f150 and press the brakes I get the trailer disconnected message. When I let off the brakes I get the trailer connected message. I have found that I have a ground on the brown lead of the wiring harness. I have traced the wiring throughout the trailer but can't seem to find any issues. Any ideas? Thanks

Mike L.

12/5/2022

Justin

1/26/2023

Mike L.

1/26/2023

Helpful Links

Andrew H.

8/2/2022

Hi I have a f150 2018, every time I pull my travel trailer my drunk battery dies. Just finished a long trip during which I had my alternator changed but still ended up with the same problem. Any ideas what could be the problem?

David B.

8/3/2022

Cory E.

7/1/2022

I got a 1973 camper and the trailer plug is gone. Can't figure out the wiring for a new one. It has red green white black wires.

David B.

7/1/2022

Koreyk

10/23/2022

Dennis P.

6/30/2022

I work for a paving and excavating company, we have a 32’, dual axel, dovetail trailer w/ 8’ hydraulic lift ramps…the trailer gets pulled by a 2022 peterbilt 567 tri axel dump truck 7 pin connector…I would like to know the best way to set up so when the trailer is being towed it will charge, or at least maintain, the trailer battery for the ramps?? Thanks in advance!

David B.

7/1/2022

Helpful Links

Joey F.

5/3/2022

Helping my neighbor out. When he connects his trailers flat wire harness to his truck during the day everything works perfectly but come night time when his vehicle sensor comes on to turn on the headlights automatically his trailer lights goes out and stops working.

David B.

5/3/2022

Jason

11/27/2022

Mike L.

12/1/2022

Mike L.

12/1/2022

John M.

4/19/2022

I just purchased a 2004 shadow master 6x12 enclosed single axle trailer. I have power at my connection on my truck but I get nothing lighting up on the trailer at all. the harness for the trailer ends up going inside the frame near the tounge. How to I figure out what's going on?

David B.

4/19/2022

Ben M.

4/10/2022

I installed self-adjusting brakes and when the tow vehicles brakes are activated I can hear a hum from the assembly (which I'm assuming is the magnet activating) but the brakes don't do anything. From an adjustment standpoint the brakes are making contact with the hub when not activated so I think their baseline adjustment is ok. Any thoughts on what I'm overlooking?

David B.

4/13/2022

Helpful Links

Gary

10/5/2022

David B.

10/6/2022

Helpful Links

David B.

4/7/2022

2 trailers;both are wired w/4wire conn. I want to add 2" recv.on larger one and tow the 2nd. I need to run 4wire conn. from Ist to 2nd, How and what do I need to accomplish this? Thank you for your time and advice.

David B.

4/13/2022

Mike R.

3/27/2022

I want to wire my trailer for tail, brake lights with left and right turn signals. The tail lights only have 2 wires and the wire I bought has 4 wires with flat plug in to truck. With only 2 wires on the tail light, what wires do I use of the 4 coming from the truck

Les D.

3/28/2022

Helpful Links

Mark B.

3/14/2022

We have a 7 pin harness on trailer. Most lights work ok but the left blinker only works when the right blinker is activated. Right doesn’t activate with left. Brake light is also inconsistent in working. Thoughts on where to start looking. This site and article is super helpful

Les D.

3/15/2022

Helpful Links

Brent G.

2/21/2022

I have a new Charmac cargo trailer that all exterior lights work properly, but the interior lights will only work if the truck is running??? I want them to be operable with the truck off and keys out out the ignition

Les D.

2/21/2022

Joe W.

12/29/2021

I have a 2017 Ford T150 van with 4/7 connector. When I have any trailer attached, the right turn signals flash really fast on the van, but the signals on the trailer don't work. Running lights, left turns, brakes, all work normal. Is this a ground? fuse? flasher plug? Everything works normal with no trailer attached.

Les D.

12/29/2021

Louis H.

12/14/2021

I have a 2011 toyota tacoma with a new T-one harness installed. I have a new 4 pin trailer harness with led lights installed on a 5x8 tilt trailer. Problem is everything works properly with my lights turned off on the truck but with them turned on: seems like the trailer brake lights are on constantly, no turn signals or variance when the brake is applied.

Les D.

12/15/2021

Helpful Links

Wendell S.

11/9/2021

I have a 1999 Chevy Silverado I was hooking up a 7 pin connector I have a light green wire coming from my wine out of my truck with no place to hook it to in the 7-pin where does the light green wire hook up to you

Les D.

11/12/2021

Helpful Links

Matt

10/18/2021

Ok so I have my wires run and ready to connect on my trailer. I am putting in new LED lights and ran a flat 4 wire connector. I know I need to run the brown wire to my black wire, but where do I run the ground wire from the light? The ground wire is only about 8 inches long. And grounds to the tongue. What do I do with the other wire on the light?

Les D.

10/19/2021

Heather V.

10/8/2021

I have a 2011 F350 turbo diesel with a factory towing package. It has two 7-way plugs, one in the bed and one under the bumper. The trailer running/tail lights stopped working. When I checked the truck 7-way plug at the bumper, I had power at the pin but no trailer lights. Trailer service checked trailer said the lights all worked in the shop both with testing and connecting to another truck. The next thing the happened was the right trailer brake/turn light was dim, then it went out. I now only have the left brake/turn on the trailer. Please help me, I believe there are several fuses and at least two relays in the wiring harness. I am not sure where to start tracing this problem.

Les D.

10/19/2021

Aj P.

9/28/2021

I got a older haulmark elite 2 race trailer. 7 pin plug. Hooked up everything. Bought new lights for it because I thought the old ones were bad because they didn’t work. All the wires under the trailer seem fine. Has a battery for electric breaks. Do I need a new battery for the brake lights and running lights to work. No lights or anything work on this trailer

Les D.

10/19/2021

Helpful Links

Carlo N.

9/28/2021

I have a 28ft toy hauler, I put new brakes on &now I have a problem no brakes.

Les D.

10/19/2021

Helpful Links

Bill J.

9/26/2021

I have a new to me, 1995 2-axle, 2-horse WW trailer. It has the standard 7-pin connector and electric brakes. All the lighting work, however, the breaks become engaged as soon as the vehicle key is turned on. I've connected the trailer to two different vehicles with the same result. Somehow the breaks are getting voltage to engage even when the break petal is not pushed. Now i can't pull the trailer because the break system is always "on". Any thoughts on what's happening?

Les D.

10/19/2021

Mokp

9/23/2021

I have a big Tex utility trailer and with a seven plug connector and whatever it drives it appears that the brakes are on I looked at the wiring underneath and somebody has connected the ground to the power for the brakes what the hell is this a standard configuration or what can I do about it

Les D.

10/19/2021

Helpful Links

Danny S.

9/1/2021

Hello. , I have a typical 2008 6x14 enclosed trailer , all the lights work great when plugged into my 2011 Tahoe but only 1 brake light and 1 blinker works when plugged into my 2001 Silverado 1500. , using the same adapter to each vehicle. Are these vehicles wired differently ?

Victoria B.

9/7/2021

Manny R.

8/20/2021

I have a 2014 GMC Yukon, 7 pin factory plug. I bought a trailer wired for 7 pin with an electric hitch. The electric hitch does not work on my truck but works on the truck the previous owner had, I believe it was a Toyota. Can someone point me in the right direction?

Victoria B.

8/26/2021

Darrell M.

8/19/2021

I connected a new 7-way to my truck for my trailer and brakes however now when everything seems to work but my running lights stay on after everything is off the keys off and they do not turn off I can unplug the main plug the tail lights will go off but if I turn the lights back on the tail light stay on again. And I'm using all standard bulbs no LEDs

Victoria B.

8/23/2021

Darrell M.

8/24/2021

Matt W.

8/17/2021

I have a travel trailer and a utility trailer and I am towing with a 2019 tundra. Both have a 7 way plug. Towing the travel trailer, everything is fine. Whenever I am towing my utility trailer it constantly shows the trailer comes disconnected. This is most annoying. I have traced it down to the trailer brake system, but was unable to figure out anything from there. I notice above it shows different wiring configs for RV and Utility. Could this be the issue? I have noticed it one other time when towing another utility trailer? Is there an adapter, that I can use to eleviate this issue?

Victoria B.

8/19/2021

Wayne F.

7/30/2021

I have a 2008 TAB trailer that has a 7 pin connector. When hooked up to a vehicle with 7 pins all lights work correctly. I have a 1994 Chevy pickup with 6 pin and a 2015 outback with a 4 pin. Using a 6 pin to 7 pin or a 4 pin to a 7 pin brake lights ok, left turn signal work ok. running lights ok. Right turn signal all lights are blinking on the trailer. What can I look for?

Victoria B.

8/4/2021

Fidel B.

7/19/2021

By screwing the connection box of my 7 pin wire under the clip of my fifth wheel m I crushed a wire and there was smoking, so I closed the master switch of the battery. The 7 pin cable was not connected after my pick up. My q question is it would be the wire of the brakes that I would have to pierce with the aim which would have caused a short circuit. Thank you for your good advice,

Jon G.

7/20/2021

Jim N.

7/6/2021

I have a 2019 GMC Seirra Denali and I bought a new car hauler. The problem is I bought it about 200 miles away and the left signal light dosen't work. Since it would cost more to haul it back than pay someone to repair it. I have checked all the connections I can find and checked the bulb all are fine. Any help will be appreciated.

Jon G.

7/8/2021

Helpful Links

Al

6/16/2021

What a great article very informative. I do have a question. I am switch my old rv tail lights to a led tail light. Upon looking at the wiring it has 4 wires coming out hooked to old light. New light has 3 wires from partsam light. I am going to systematically test each to find out what works what. But does any of those effect my trailer brakes, like if I hook them up wrong? Because I’m going to have to combine 2 of the wires together so they can connect to one of the three wires? Right help!

Jon G.

6/22/2021

John B.

11/24/2024

Jon G.

11/25/2024

Plumberjohn

5/24/2021

I have a 1973 slide-in truck camper. I'm trying to connect the electrical pigtail from my 2002 Chevrolet Silverado. The slide-in truck camper had a 6 Pin round (male), and the truck has a 7 Blade round (male). Is there an adapter or cable to make this possible? I'm not able to determine what pin does what on the slide-in truck camper. Any advice is greatly appreciated! Thanks!

Clifford B.

5/23/2021

I have a 2009 Ford F 150 with the 7round plug and a 4 flat wire plug I can use either one just bought a new set of magnetic lights with red and orange lens and already have the led lights mounted in the trailer only all lights work when head lights on truck are turned but no brake or turn signals I have a 7 pin to flat 4 round connector why is it that the lights work but not the brake or turn signals

Jon G.

5/25/2021

Gary S.

5/16/2021

I have a Wells Cargo Auto Hauler trailer. Originally in the black box that houses all the connections (located on the front tongue) there was a diode in-line with one of the wires. My friend borrowed the trailer, and somehow burnt out (melted!) the wiring. Now the back up lights on my 2006 Dodge Ram 3500 stay lit when I plug in the 7 blade connector. How can I fix this, or what part/wiring kit do I need? Much tanks.

Jon G.

5/17/2021

Jim S.

5/15/2021

I have a 2021 VW ID.4 which come pre-wired for 7 pin connections, while the kayak trailer on has only 4 pins. What solutions are there

Jon G.

5/17/2021

Jake W.

5/8/2021

the 2003 ford psd wire colors are not the same as you are claiming. at least on my truck. i know. im trying to rewire a new plug in right now. keep blowing fuses.

Jon G.

5/10/2021

Shannon

5/5/2021

How can I run a 12v fuel pump into a 7 pin and control the power from a uplifter switch in the cab of my truck Ford F-250 super duty

Jon G.

5/6/2021

Steve

5/3/2021

I have a 2020 G M C truck I wonder can I use the light wire to charge my battery to my power winch it a lawn mower battery ? If I turn my lights on while running ? That the flat 4 plug .

Jon G.

5/4/2021

Ben

4/30/2021

Without turning the mini van on I have full lights on, brake, left and right work perfectly. New cable harness. I need to disconnect the trailer connector to kill the running lights. Any ideas

Jon G.

5/3/2021

Bob C.

4/20/2021

Hi. What is the best way to add a third brake light on a camper shell mounted on a 2002 GMC Sonoma SLS? I have a junkyard rescue shell that does not have a third brake light and will mount an aftermarket LED but I am not sure if a hot wire is available. Just need advice from more knowledgeable folks

Jon G.

4/22/2021

Edward R.

4/18/2021

Hi! I have a 2012 RAM 1500 quad cab which has the standard incandescent lights. I’m building an Wind Stream 24ft utility trailer with LED LIGHTS. Question is “Do I need to have a converter to control the return voltage to control and protect the fuse panel in the truck?”

Jon G.

4/20/2021

Craig W.

4/16/2021

I need to wire a four flat to the back of my camp trailer in order to connect to small aluminum trailer which already has a four flat. Any advice on this project would be helpful.

Jon G.

4/20/2021

Gordon S.

12/11/2021

Matt S.

4/2/2021

Is there a ASME, NEMA or other standard that controls the pin diameter and spacing of 4-flat plugs? I have several trailers with 4-flat plugs and the spacing and diameters, while similar, do not appear to be the same, which makes it difficult to plug into some and loose connections on others.

Jon G.

4/3/2021

Butch

3/29/2021

I have a 2001 Ford f250 super duty truck, I just purchase a sure trac enclosed trailer and moved to Florida. All the lights work on the trailer however I cannot get the Interior dome lights to work. I watched a you tube video to where a man said that his Chevy truck did not have the fuses installed in the fuse box, can anyone tell me what fuses I need to check and have installed? Any help would be appreciated.

Jon G.

4/2/2021

Willie J.

3/28/2021

Hey, I just brought a used Carry-On trailer with a 7way flat and it have three wires on the left side and two wires on right side running from the rear for clearance marker and tail lights . With only one oval LED fixture at rear on each side. Do I need a 5 to 4 converter? My truck is 2010 Ford F-150 with turn/brake is feed from the same wire.

Bill F.

3/25/2021

Need to go from 4 wire flat on motorcycle to 9 wire round on a can am motorcycle trailer. It is a 2018 Honda motorcycle.

Kef G.

3/25/2021

Drew M.

3/16/2021

I have 6 wires going into a 7 wire plug. None of the wires are blue and my electric brakes do not work. The only blue wire I see goes to a junction box on trailer w/black wire. How should I wire the plug? Should the black act as the blue wire? Very frustrating

Jon G.

3/18/2021

Richard H.

3/14/2021

I am rebuilding an old aluminum trailer and have purchased new replacement sidemarker lights. Because the metals react to each other and corrode, I have put a silicone gasket between the two metals. Will this cause a grounding issue? I have done the same with the new taillights. Thx!

Jon G.

3/15/2021

Dan O.

3/6/2021

Question, not sure if this is the correct location to ask a question. But here it is. I have a 1982 Sunline camper trailer. I replaced the standard bulbs with new LED tail and running lights. Their was green and white wires at running light locations. Here’s the issue, when the running lights are OFF the turn and stop lights work fine. When the running lights are ON the turn and STOP lights DO NOT work.

Jon G.

3/8/2021

Roger K.

4/10/2021

Emmanuel A.

3/2/2021

Hi there a have a small car dolly 7pins plug and the colors the my has is yellow Lt, white GD, green Rt but i am confused theres is one wire yellow/brown and green/brown i dont know what terminal are those TM or EB or AX. I need some help please. Thank you

Jon G.

3/4/2021

Dave H.

1/28/2021

I really don't like the Idea of "showing" electric trailer brake wire being grounded to the trailer axle. My axles move and is some what going to have a voltage drop when finding ground. My preferred method is to connect to the ground wire and keep the frame ground out of my schematics. By adding undetermined amount of resistance to the brakes you may end up with each wheel or at least each axle getting a different current flow and uneven braking. Thank you for having all this information quick and easy to find.

Gordon S.

12/11/2021

Show All (103) Replies

Hide Replies

on Wiring

Videos

for Wiring

Help Articles

for Wiring

Expert Answers

for Wiring

It sounds like you are speaking of the wires for the brake magnets. If this is correct, you will need to connect one of the wires to the brake controller output wire on your trailer connector and the other wire will need to be grounded to a clean…

view full answer...The difference between the Class II and Class III hitches has to do with their Gross Trailer Weight (GTW), their Tongue Weight (TW), and their Hitch Receiver Size. Class II trailer hitch receivers have a 1-1/4 inch receiver and can be rated up to…

view full answer...Since wire color codes are NOT universal, we always recommend wiring by function, rather than wire color. If you look at the Trailer Wiring FAQ article I have linked you to, you can see some diagrams showing the proper way to wire a vehicle and…

view full answer...A 4-Way trailer connector has the basic lighting functions only; running lights, left turn signal and brake lights, right turn signal and brake lights, and ground. A 7-Way has these functions and a 12 volt circuit, a circuit for electric trailer…

view full answer...That's a very good question, we tend to be extra cautious and say to use 10 gauge wire because that would be more than enough. When you get into longer trailers that will end up using a lot of wire the heavier gauge wire becomes more necessary.…

view full answer...When wiring a trailer connector, it is best to wire by function, as wire colors can vary. We have an excellent wiring diagram on our website, I will provide you a link so you can look at it. If you are looking at the inside of the trailer connector…

view full answer...You have it right so far, the 4-way connector is just as you have stated. Remember that Yellow has a L in it so that is the left side brake/turn signal and green has a R in it so that is the right side brake/turn signal. The colors for wiring a 7-way…

view full answer...If your trailer has 7 wires running all the way back to the brakes, then yes, you can tap into the existing wiring. Each of your new brakes will have two wires for the brake magnet. One wire is for 12 volt power to the brake magnets and the other…

view full answer...The brake wire providing voltage is wired in parallel, with one lead from each magnet being grounded to the trailer frame. We have a great Wiring Help Page that shows a diagram, I will provide a link to it below.

view full answer...Each lamp needs to be grounded either through its mounting studs being in direct contact with the trailer frame or by having a jumper wire ran from the lamp to the trailer frame. Ground the trailer connector at the front of the trailer, which will…

view full answer...It could be a tow package fuse on the vehicle. Use the owners manual to find the locations of fuses/relays related to the tow package wiring to check them and replace as needed. If the issue is not a fuse or relay then you can test the vehicle side…

view full answer...Going by the colors that you mentioned, it sounds like you have the typical set-up, green wire for right turn and brake, white wire for ground, yellow wire for left turn and brake, brown with green wire for right side running lights, and brown with…

view full answer...Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"Ordered the part on Saturday and had it by Wednesday. $35-$75 cheaper than I could find anywhere else. I plan on using this site again."

Craig A.

10/31/2025

Hi I have a utility trailer that I am having trouble with getting the left blinker to work. It works when the running lights are on, brakes are applied, and if I turn on the hazard lights. I have a 4 pin connector. I put the pin for the right side in the left side hole and the left side blinker will work. I'm stumped. I have a new connector I'm going to try as soon as I finish this post. Is there any other troubleshooting other than ground is good? Thanks