Wiring Trailer Lights with a 4 Way Plug (It's Easier Than You Think)

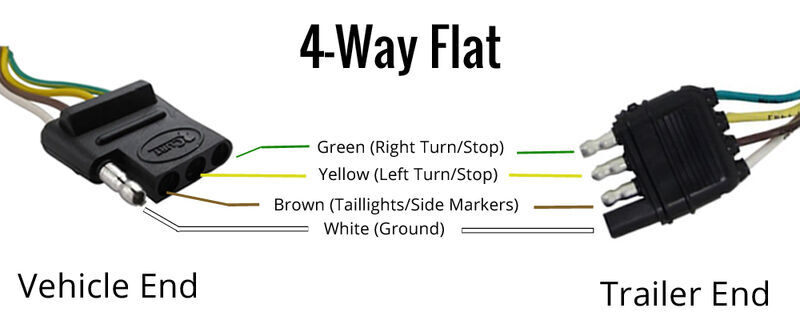

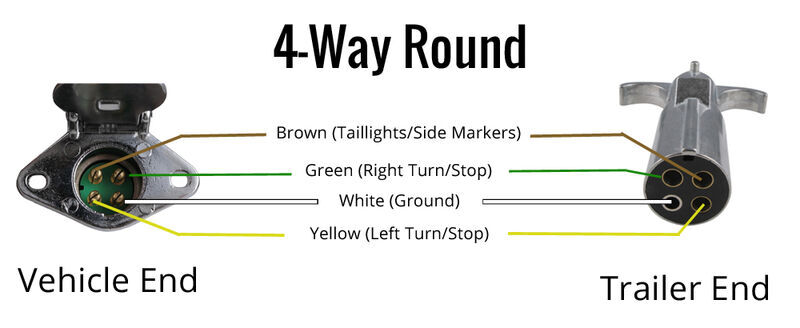

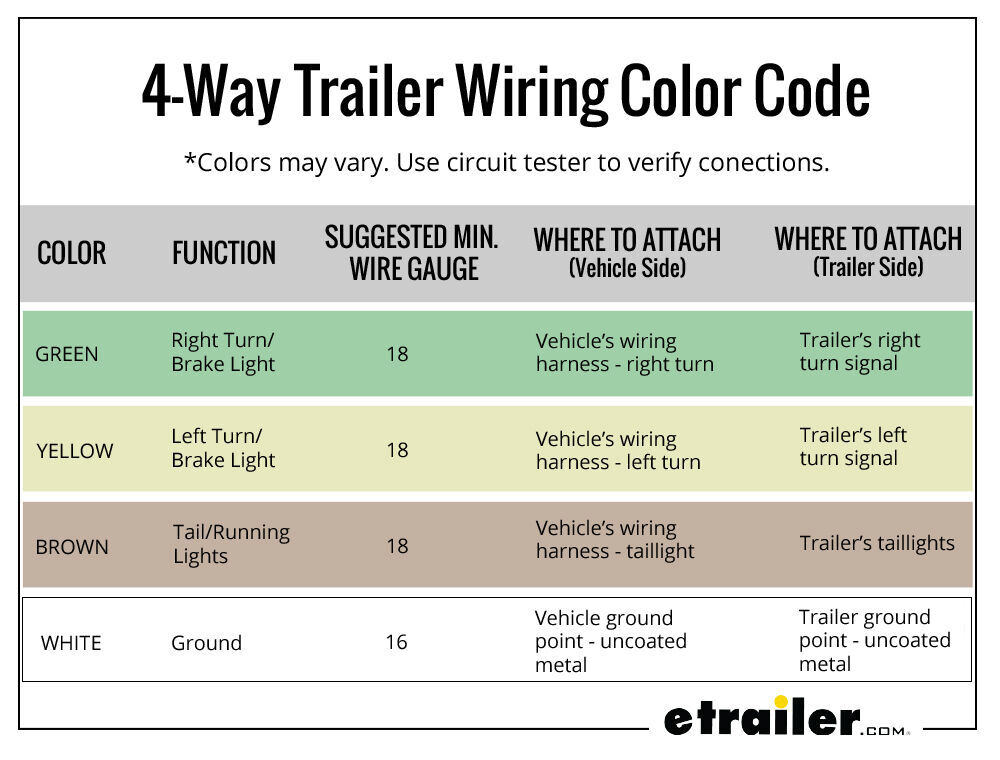

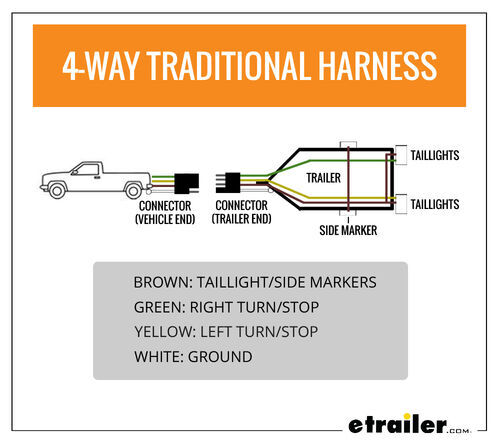

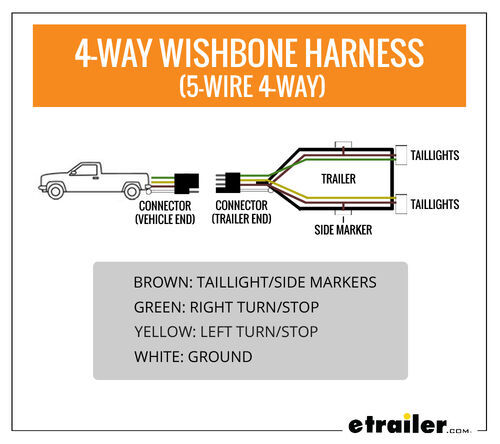

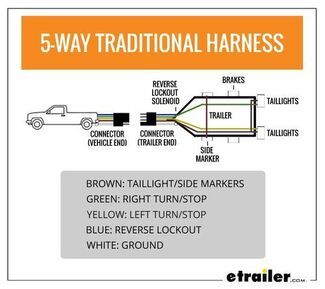

What is the Color Code for 4-Way Trailer Wiring?

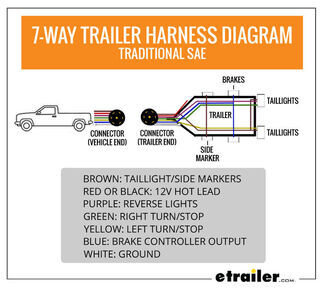

Green: Right turn/brake light Yellow: Left turn/brake light Brown: Tail/running lights White: Ground wire

Wiring a Trailer with a 4-Way: Step by Step

Trailer Side

Step 1: Prepare for Trailer Wiring Installation

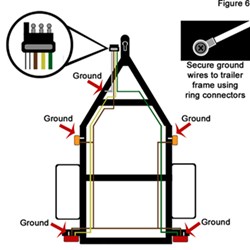

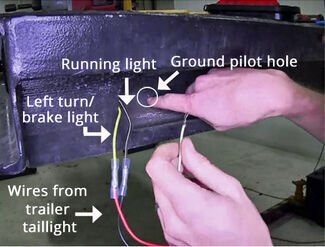

Step 2: Connect Ground to Trailer Frame

Step 3: Run Wires Along Trailer Frame

Step 4: Make Trailer Connections

Vehicle Side

Some vehicles require you to route a power wire from the harness to the vehicle battery because the vehicle's electrical system cannot handle the amperage draw of the trailer lights. For a breakdown of how to route a power wire for a trailer wiring harness, click here. If the vehicle connector is under the vehicle, use a mounting bracket to attach it to the vehicle. This will help prevent damage that may occur if the connector is left dangling. Use a small amount of grease on all electrical connections—the plugs on your automobile and the 4-pole connector itself—to help prevent corrosion.

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"I like the easy of navigation through the site. It only took me a couple of minutes to place my order. Thank You I will shop this sight again in the future."

Kevin

Manchester, MD

Ross B.

8/30/2024

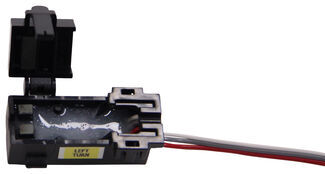

Unfortunately the three light regular bulb tail lights are rare these days. Most led tail lights have five wire pig tails: Grey- ground, Yellow - turn, Red- brake, Green - light. I found it an extremely difficult task to figure out the connection to a four wire harness.