Wiring - Quick Disconnects

Contact and Help

Easy place to shop. Fast delivery and great products. Very happy with my purchase.

Ed

Boynton Beach, FL

Wiring Solutions for Your Trailer Needs

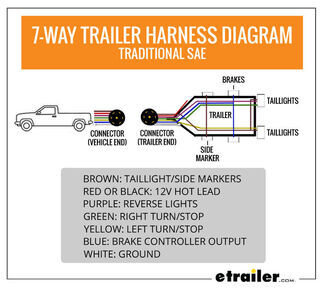

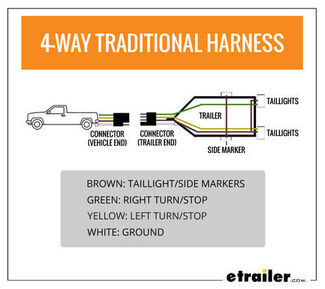

Whether you're restoring a classic trailer or upgrading your current setup, quality wiring is essential. Look for durable, heavy-duty materials that can withstand the elements and provide reliable connections. Consider the specific needs of your trailer,

Peterson and Tow Ready are popular choices for their reliable and durable wiring solutions. These brands offer products that fit well with various trailer setups and are known for their longevity and performance. Choosing a reputable brand can save you time and hassle in the long run.

Start by selecting a wiring harness that matches your trailer's configuration. Consider upgrading to LED lights for better visibility and efficiency. Ensure all connections are secure and test the system thoroughly before hitting the road to ensure everything is functioning correctly.

Use high-quality connectors and ensure they are compatible with your wire gauge. Heat shrink connectors provide a secure, weather-resistant seal. Crimping tools can help achieve a tight fit, reducing the risk of connection failure. Test connections before finalizing to ensure everything works as expected.

Be cautious of thinner heat shrink shielding that may split during crimping. Ensure connectors grip the wire securely to avoid a high failure rate. Regularly inspect your wiring for wear and tear, especially in high-stress areas, to prevent unexpected failures.

Focus on the gauge size and conductor count to match your trailer's requirements. Opt for jacketed wiring for added protection and durability, especially in wet conditions. Quality materials ensure longevity and reliable performance, so avoid the cheap stuff that might not hold up over time.

Filters

Filters