Wet Equalizer Bolt with Locknut and Grease Zerk for Double-Eye Springs - 3" Long

- All Info

- Reviews (748)

- Q & A (0)

- Videos (2)

- Photos

Redline Trailer Suspension Parts - 126B2

- Suspension Bolts

- Camper

- Car Hauler

- Utility Trailer

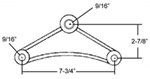

- 2-5/16 Inch Long

- 9/16 Inch Diameter

- Redline

3" Long suspension bolt comes with a locknut to secure equalizer to hanger. Grease zerk allows for easy lubrication to keep moving elements functioning properly.

Features:

- Secures equalizer to center hanger of tandem- or triple-axle trailer suspension system

- Allows for easy lubrication to keep moving parts functioning at their best

- Includes locknut to secure in place

- Press-in zerk

Specs:

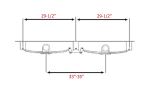

- Overall length: 3-1/2"

- Bolt length (including threads): 3"

- Usable length: 2-5/16"

- Bolt diameter: 9/16"

- Thread size: 9/16"-18 fine

- Bolt head size: 13/16"

126B2 Wet Shackle Bolt with Nut and Zerk

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for In-Depth Review of the Wet Equalizer Bolt with Locknut and Grease Zerk for Double-Eye Springs

Hi there trailer owners. Today we're going to be taking a look at Redlines replacement shackle wet bolts. These bolts will make a great replacement for standard bolts or wet bolts if you are performing suspension work here on your equalizers and leaf springs and you find that they're all wore out. Over time your bushings can wear out, and once the bushings start to wear out, play will develop inside which will allow movement of the bolt inside of your suspension components. And that small movement will allow the bolt to travel up and down. And this little bit of movement is going to cause wear on both the bushing and the bolt and over time it will eventually destroy the bushing and it will also make our bolt a smaller diameter with an uneven wear pattern on the inside, so you'll need to replace it when you're putting a new bushing in or else you're still going to have that play from the bolt wear.What's nice about these bolts is that they do have a grease fitting on the end so you can grease your bushings.

Many of your factory suspension setups will have non greasable bolts with bronze bushings. And if you have that combination, those bushings are eventually going to wear out. They need lubrication. So upgrading to these will allow you to lubricate your bushings and your bolt to ensure that they don't seize together and also provide a lubrication coating between the two so we have no metal on metal contact, which greatly reduces the amount of wear.Wherever these bolts are installed, we have bushings in them and these are the design movement point for your suspension system. The bolt will pivot inside of the islet here on our leaf spring.

Same with our equalizer in the center and at the bottom here, all of these components move. And over time they will eventually wear out the bushings on the inside. But being able to lubricate them greatly decreases the amount of wear.What I also like about these bolts as they can be used with any type of bushing, too. If you're going to be using with a bronze bushing, they're great because they will fit in there and you also have a way to lubricate them, but you can also use them with plastic bushings. Many of your plastic bushings are self lubricating, so you don't want to lubricate them because the grease can potentially break down the plastic of those types of bushings

It is a 9/16 diameter bolt. Included with your bolt, you are also going to receive a lock nut, so when you're replacing the bushings on your worn out suspension system, I highly recommend replacing the bolts at the same time. It's going to make the installation easier. Often when you're taking apart your old suspension and you're planning on greasing 00:02:46 those bolts, the threads and things like that can easily get nicked and damaged because you do have to drive out your old hardware. And you can use the nut to help protect it when you're driving it out with a hammer.

But depending on how tightly they are seized inside your suspension system, you may still end up mushrooming the end and needing a replacement anyway. Replacing it with the lubricatable end here is going to further increase the life, so that way once you're done fixing your trailer, you can just keep maintaining it so you don't have to make those repairs down the road.They're fairly easy and straightforward to install. You can pick up as many as you need for however many bushings you're replacing in your suspension system. Let's go ahead and go over the installation together so you can the confidence to do it at home. We'll begin our installation by getting our tires out of the way. We're just working on the back axle for this one. So we don't need to remove our front. But depending on what all you're doing, you may need to remove yours as well. When removing your wheels, you want to make sure you got your trailer supported on the frame by jack stands. So you can use just a regular floor jack to lift it up.Once you've got all your tires out of the way for the area you're going to be working in, we can then start removing the bolts for wherever we have damaged bushings. We recently just had a new equalizer installed here and you can see we've got new bolts and shackles and an equalizer, but the bushings weren't replaced inside of the leaf spring here. So we're going to tackle that as well because we still got a little bit of a clunk noise because that bushing's wore out. To replace the bushings, you just needed to remove the hardware first. So for this particular set up here, the bolts are pressed into these shackles on the head of the bolt side. So we're going to remove both of these nuts and take the two out at the same time.We're going to take our bolts off. The bolt sizes can vary depending on your particular trailer. For ours, we're going to be using a 7/8, and you may or may not need to hold the backside of the bolt when removing these. They are supposed to be stuck inside of here, but over time they do rust and things wear out and they may not be. So it's not a bad idea to put a wrench on the other side to hold it.If we place our floor jack underneath the U bolt on our axle, we can relieve a little bit of pressure on it to make it easier to get the bolts to come out. Now what I'd like to do to get them out is I like to just thread the nuts back on there just a little bit and then tap them out with the hammer. Putting the nuts on it just helps prevent you from damaging your threads when you're tapping on them. And we can just slide it out there and you can see on our equalizer, we've got a brand new bushing in there, but on our trailer here, we've got an old one. And this old one here is so worn out that I can actually just push it out. Now if you we're unable to just slide out your worn out bushing like this, one of the best things to use to take them out as you can use an old bolt.So if we use another bolt that's slightly smaller and just place a flat washer on it, we've got a nice flat solid surface to drive it in. And we know since we're hitting all the way around, we're not going to ding up the outside of our bushing here with our hammer as we're driving it in. So we're just going to hold it in place and we're just going to tap it in with our hammer. A lot of times these tap in pretty easily. Every now and then you got to hit them pretty hard depending upon the rusty condition of your leaf springs.We can now take our new wet bolts and we can slide them into our shackles. Now if your old shackles are all worn out and the holes all wallowed 00:06:53 out, then I would recommend replacing them. We've got replacements here at etrailer, but if they're just a little bit of surface stress on them and the holes are fine, then you're okay. You can just slide your bolts right into them. Once you've got them slid in, we can come over to our bushing here and align them up. It is a bit of a snug fit. Sometimes you need to adjust the jack a little bit. WE're just going to line those up until they slide through.On the other side. Now we can take the other shackle and place it on there and then thread our nuts on. We can now tighten up our nuts. Now what you're going to want to do is hold the backside of your bolt with your wrench, because our bolt does have splines in it and it's going to spline into the inside shackle here, because the head of the bolt here has got those splines. And we don't want it to spin while we're tightening it down because it's going to rip the splines off and prevent it from working like it's supposed to. So we want to hold it steady, and then tighten it down and that will draw the bolts into the shackle and draw them tight together. And I do like to work back and forth with them just a little bit just to make sure that they are going to get pulled in.Once you've got them tightened down, it's always going of you to double check yourself and look here on the backside. You want to make sure the head of the bolt is flush all the way up against the shackle here. Sometimes the splines will prevent the bolt from going all the way in and it's not that it's preventing it from going in, just means you need to tighten it tighter until it draws it all the way flush.We can then go back and lubricate our bushings. Now we're only going to be greasing the bronze bushings, so that's going to be just this top one here on the leaf spring. Now that we've got our wheel back on, we can torque it to the manufacturer specifications and we're ready to hit the road.And that completes our installation of Redlines replacement shackle wet bolts.

Customer Satisfaction Score:

99% were satisfied with this product

1% of customers were not satisfied

- etrailer mistake

- Product did not meet expectations

- Wrong item was ordered

Ratings & Reviews

4.7

741 reviews

Fit perfectly

just what we needed

Great product and service.

Everything I ordered on Sunday arrived Wednesday morning & of very good quality

Exactly the same as original from the 1 980's.

Short time to get and good product

well made.

Great product !!! Speedy delivery

Got the part I ordered and it was delivered quicker than expected.

Just as represented. Promptly delivered, ready to install.

Perfect fit !! Quick delivery (which I needed !! )

See what our Experts say about this Redline Trailer Suspension Parts

- Wet Bolt Recommendation For the Roadmaster Comfort Ride Leaf Spring Suspension KitThe Roadmaster Comfort Ride Leaf Spring Suspension Kit w/ Shock Absorbers # RM-2460-2570 will not include wet bolts. This is due to the system using slipper springs to replace the double eye springs that come on most trailers. With the slipper springs you will only be able to use one Wet Bolt # 126B2 for each leaf spring, 4 total are needed for this kit. The wet bolts are a better option as they will keep water and rust from building up inside the leaf spring which leads to the spring...

view full answer... - Limited Tire Clearance with Stock Tire Size on a 2006 Forest River Cherokee 27QWe recommend having a minimum of 3" between the top of the tire and bottom of the fender in order to allow for proper suspension travel. However, based on the photo you sent I believe you need new leaf springs as the ones you have appear to be almost completely flat. This has then compromised your tire clearance. The flattened leaf springs could either be a result of overloading the trailer or just general wear. In order to replace them you would need to know your axle capacity and the...

view full answer... - Switching from Standard Equalizers to Road Armor Kit and Recommended Shackles + BushingsYou will be able to use the Road Armor Shock Absorbing Equalizers since they're fairly close in dimensions (6" wide x 3-1/4"). I recommend pairing these equalizers with the Never Fail Tandem Axle Suspension Kit # LC281285 which comes with 2 different lengths of shackle straps (3-1/2" and 4-3/8" bolt hole to bolt hole) to accommodate for the change in height, new bolts and bushings for your springs. One of the great things about this kit, aside from it being high quality and durable, is...

view full answer... - Can E-Z Flex Rubber Suspension System Work w/ Wide Trax Trailer SuspensionI have a possible solution for you, but unfortunately the E-Z Flex Heavy Duty Rubber Suspension System such as the 5-5/8" Equalizers # K71-652-00, will not work with the Wide Trax suspension on your trailer. The axles on a Wide Trax system are spaced further apart and the required equalizer components are significantly larger than the E-Z Flex Systems. A much larger equalizer like the 14-5/8" Equa-Flex Cushioned Equalizers, part # LC314336 may be the correct length. You will want to measure...

view full answer... - Availability of Wet Bolt Kit for 2024 Brinkley Z3610Hey Jonathan, we have replacement wet bolts with the part # 126B2 which you could use for all of the bolts in your Brinkely's suspension.

view full answer... - How to Determine Hanger Spacing for Tandem Axle Trailer Suspension with 26 Inch SpringsThank you for providing the specs for the suspension components that you already have. Correct hanger spacing really depends on the components being used such as springs, hangers and equalizers. Most of the hanger spacing dimensions that we have are based on our preassembled kits, so we will use that as a foundation for your setup. First, I would either replace all of the front and rear hangers with 2-1/2 inch tall hangers like part # 115918 or replace just the center hangers with 2-1/2...

view full answer... - Trailer Suspension Wet Bolt Not Taking New Grease Most likely there is some old grease inside the bolt that's clogging things up. You can raise the trailer up and remove the wet bolt in question to give it a thorough cleaning or just simply replace the bolt altogether. Unfortunately there's not a good way to clean it out while it's still in place. If you would rather just replace it then you will just need to take a few measurements to make sure you get one that's the same size. For example the Redline Wet Bolt # 126B2 has an overall...

view full answer... - Replacement Suspension Components for 2024 Big Tex 16GNHi Conrad! That doesn't sound good, hopefully it didn't cause you too much of a problem when those bolts failed. I would be happy to help you find some upgraded parts. However, we don't have a way of knowing what is on a particular trailer. It looks like you have 8k axles with a slipper spring suspension on there so there isn't a lot that can be swapped out/upgraded. Depending on your bolt measurements you may be able to add wet bolts like # 126B2. If you can get your leaf spring measurements...

view full answer... - Correct Track Alignment Replacement Hanger Bolt RecommendationWhat you'd want is the replacement suspension bolt part # 166079. This is 9/16 inch in diameter like you need and is 3-1/2 inches long too. It comes with matching nut as well.

view full answer... - Dexter E-Z Flex Suspension Kit For 2008 Jayco Triple Axle 5TH Wheel CamperThe Dexter E-Z Flex Suspension Kit # K71-657-00 is a universal suspension kit but you will need to confirm a few measurements on your 2008 Jayco 5th Wheel to ensure a proper fit. First this kit is only designed to work with double eye leaf springs that are 1-3/4" wide. The equalizers in this kit are designed to replace equalizers that are 7-3/4" wide for the short equalizer and 8-3/8" wide on the long equalizer. They are 2-7/8" tall and use shackle straps that are 2-1/4" from hole center...

view full answer... - I Need Wet Bolts And Shackles For My 2016 Forest River Wildwood 28DBUDWe will definitely have kits that will work for your trailer. In order for us to get the correct parts, you will have to take some measurements from your trailer. Unfortunately, there is not an universal size for shackles. You will need to measure the center to center distance on your shackle straps. If you measure your shackle straps and they measure 3-1/8", you will need the Replacement Shackle Strap - 3-1/8" Long, part # 115208GALV. You need to measure the wet bolts for the same reason....

view full answer... - Replacement Bushings and Wet Bolts for Slipper Springs. Hey Viencent, thanks for the information! To replace the bushings in your slipper springs, I recommend the Dexter Bronze Bushings item # K71-291-00. These have a 11/16" outer diameter and will replace all four of the bushings on your car hauler. These are made of bronze so they'll last quite a bit longer than plastic bushings. To upgrade to wet bolts, I recommend the Wet Equalizer Bolt with Locknut and Grease Zerk for Double-Eye Springs - 3" Long item # 126B2. This is a 3" Long x 9/16"...

view full answer... - Wet Nut and Bolt to Use with Winnebago Trailer SuspensionHey Daniel, that's a bummer to hear they didn't do all of the work you paid them to. For wet bolts we have the # 126B2 which comes with a nut. To pick out a bushing though I would need to know the outer and inner diameter of what you have currently on the spring.

view full answer... - Heavy Duty Shackle Kit for Lippert 4,400 lb AxlesFor a heavy duty shackle kit that would work well on your 4,400 lb axles we have the Dexter HD shackle kit part # K71-358-00. These shackles are really thick at 1/2 inches.

view full answer... - Replacement Wet Bolts and Bushings for Keystone Impact 5th WheelThe Step Wet Bolt for 1-3/4" Double Eye Springs # 34007-187-00 you were looking at have a usable length of 2-1/4", which it sounds like match your existing bolts and would be typical for 1-3/4" wide springs. You will need a 7/16" locknut for this bolt, which is available with the Fastenal Lock Nut - Zinc Plated Steel - 7/16"-20 - Qty 1 # 1137306. You could also use the Redline Wet Bolts # 126B2, which come with locknuts included. For the bronze bushings I recommend using the Bronze Bushings...

view full answer... - Wet Bolt For 1-3/4" Double Eye Springs Without Silver CoatingThere is a similar but not exact version of the Step Wet Bolt for 1-3/4" Double Eye Springs # 34007-187-00 without the silver coating. The closest is the following: - Wet Equalizer Bolt with Locknut and Grease Zerk for Double-Eye Springs # 126B2 The # 126B2 has the same 9/16" diameter and usable length of 2-5/16" but has a 9/16"-18 fine thread compared to the 7/16"-20 thread of the bolt you asked about.

view full answer... - Wet Bolt Spare for Trailer Suspension of 2024 Brinkley Z3100Hey Chris, for a spare wet bolt for your trailer suspension the part # 126B2 would be a great option that is the correct size and has the zerk fitting for easy install of grease as well.

view full answer... - Looking for Trailer Suspension Wet BoltHey Craig, we don't have the exact wet bolt you are in need of. Closest option would be the part # 126B2 that you referenced but it is a little shorter. I attached a dimension picture for it for you to check out. Are your leaf springs 1-3/4 inches wide? If so, this SHOULD work assuming everything else like the hangers are standard and nothing unusual.

view full answer... - Upgrading Trailer Bushings Greasable Bolts and Equalizer Suspension Parts on a Alpenlite 5th WheelInstalling brass bushings of the proper inner and outer diameter and length is possible. In my experience brass bushings do not last any longer than nylon bushings and they are much harder to find in the correct size. At this time we do not carry brass or bronze bushings properly sized for double eye leaf springs. Upgrading to wet shackle bolts would be a good idea and would increase the life of the suspension components, no matter the construction. You will need to match the length and...

view full answer... - Recommended Wet Bolts for Use w/ a Roadmaster Comfort Ride Leaf Spring Suspension KitWe have the wet bolts you need but all of our kits will come with parts you do not need to install the Roadmaster Comfort Ride item # RM-2470-2580. Instead you will want to purchase individually the Wet Equalizer Bolt with Locknut and Grease Zerk for Double-Eye Springs item # 126B2.

view full answer... - How Do You Measure Wet Bolts On Highland Ridge 5th WheelHello Arthur, thanks for getting in touch. To measure a wet bolt you will just need to confirm the length and diameter of the bolt. Most wet bolts are about 3" long and 9/16" diameter like the Wet Equalizer Bolt with Locknut # 126B2. You will find the dimensions of this bolt below. Please compare this to what you have and see if it is a match. If you need a different size just let me know and I am happy to look into it.

view full answer... - Replacement Hanger Kit and EZ Flex Equalizers for Trailer with Tandem Dexter EZ FlexHey Fred, the closest kit we have to the hangers you have now would be the part # APT4 which comes with hangers that are 3-1/4 inch front and rear and 5-7/16 inch for center. Then for EZ Flex equalizers to swap out what comes with that you'd want the part # K71-654-00. Then for wet bolts you'd want the part # 126B2 and you'd be set.

view full answer... - Bolt to Use with etrailer Leaf Spring # e27SRHey Steven, for a shackle bolt to use with the etrailer leaf spring # e27SR we have the part # 126B2 which would work great. It's correct size and has a grease fitting for easier greasing. Do you have everything else needed?

view full answer... - Wet Bolts that Can Be Used with Road Armor EqualizersHey Michael, so we know that the bushing part # D014-077-00 does fit the Road Armor equalizers but it's not a Road Armor brand as that's not available. Then for wet bolts you can use the part # 126B2.

view full answer...

Do you have a question about this Trailer Suspension Part?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.