My Trailer Hitch Doesn't Fit

Use a Table Vise

Find an Open Step

On the Floor

Against a Wall

On the Vehicle Frame

With a Jack

Jack

5/6/2025

I ordered a Curt hitch from Amazon for my 2025 Kia Sorento. The hitch was over 1/2 inch too narrow to fit the bolt holes. Amazon would not allow returns or refunds, sent me to Curt, and I got a rude customer service person who belittled me, but finally sent me a replacement direct from Curt only if I cut the original hitch and sent them a photo. That hitch was the same dimensions as the first. The told me to install the side bolts first and use the car frame to stretch the hitch, but Kia said no and that it could void parts of the warranty. Curt then said to use a bottle jack to stretch the hitch, but bottle jacks are meant to be used vertical and not horizontal, plus the distance between push points was 27 inches and I would have to use something to make up that difference. I wanted to see how much pressure it would take to stretch the hitch so I used a bar clamp maxed out and it only moved it 1/4 inch and when released an hour later, it went back to its original dimension. No way I would put a bottle jack in that precarious position to stretch the hitch and risk injuring myself or others. Curt was not cooperative, accused me of not contacting them when the issue was noticed and cutting the hitch without their direction, all of which was false and if they had just read the email thread, they would see their rep told me to cut the hitch. They directed me to this page on flexing the hitch and said their hitch was within their spec. How can they expect a DIY person to modify their hitch at home with limited tools, ridiculous. They refused to refund me and send me a return shipping label. Not a reflection on etrailer, but on Curt. It's been frustrating, why can't they just make the hitch to fit properly?

Jameson C.

5/13/2025

Mr. C.

12/14/2024

I was worried about the trailer hitch being short by nearly 3/4 of an inch. I looked at all the ways to spread it out to be an exact fit. Working with my son I wanted to put it on first to determine how far to spread it. I then realized that the natural process of torquing the mount bolts on the vehicle would do the trick. It did and now it’s a snug fit. Don’t go to the trouble of spreading it until you try seeing if the gap is small enough to snug it up with your torque wrench. Thanks Etrailer. I saved $1,200 since the dealership wanted to charge me more than that for the hitch and installation.

Tony M.

9/6/2024

Had the same problem with the Curt hitch. Next time, I'll measure the distance between the bolt holes before I try to install.

Nick

8/1/2024

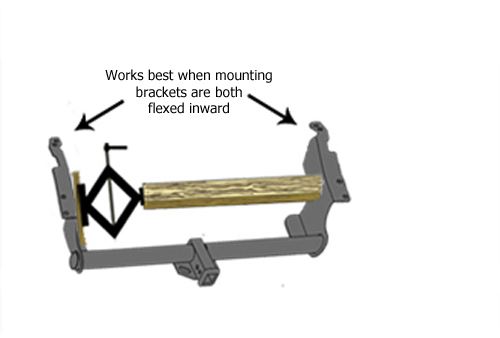

I took my hitch to a mechanic to be installed because my rav4 mounting holes was rusted and needed to be rethreaded. The mechanic rethreaded them but then informed me of the bent hitch not lining up. He didn't have tools to try and fix it. I requested a return and ship new one. When i got home i told my neighbor about my misfortune. We attempted the 2x4 and scissor jack method. It was dicy because things move under pressure and a few times the mechanism jolted out. Not quite a safe way BUT it did shaped the flange enough so with both of is on the garage floor and positioning the hitch we could make the bolts catch the nuts in the car frame and slowly tightened with rotating from bolt to bolt little by little. Not ideal story. ETrailer should improve on this. but the remedy worked

David P.

12/16/2023

Message to the welding shop employees at etrailer: it seems that the two pieces that attach to the frame may get bent during shipping. Wouldn’t it be easy to stop that problem by having a final step in manufacturing be to cut a 2x4 to the inside distance between the two plates that get bolted to the frame, and use a lag screw through a hole in each plate and deep into the end of the 2x4. David P.

Mike L.

12/17/2023

David R.

10/17/2023

Similar story to others on here, I spent a day prepping the vehicle, getting the bolts in place and wrestling the hitch into position only to find out it would not fit because the outer tangs were too close together and will not fit over the vehicle mounting beams. Now I have to wrestle it out and try to figure out a way to bend it into hopefully a size that will fit. The correct clearance dimensions of the relevant pieces should be included in the instructions so the hitch can be measured BEFORE going through this ordeal. This is apparently a common problem and it is inexcusable that the installation instructions do not address this. DO BETTER!

Mike L.

10/17/2023

Taylor A.

4/29/2024

Mike L.

4/30/2024

John S.

6/5/2025

Mike L.

6/18/2025

William K.

7/21/2023

I spent three hours lying on the ground under my RAV4 trying to install this receiver, supporting it with my knees and belly. It just would not fit. I pulled it out, took a closer look and realized that one end had been bent inward over an inch from UPS mishandling. Apparently it was dropped from a height in the thin box it was loosely shipped in. I called and was told that this is normal and I can fix it with vice grips . . . "Whoah! Vice grips?! No. He helpfully sent me this page to help fix the problem. (Nothing about vice grips here) I was able to wedge it into a utility trailer frame and brute force it into shape. Now I'll go back out and try again. Meanwhile, I'll recommend that you pack things better. A plank of wood bolted across the wings might hep. Also some warning that this is a regular thing to expect so your customers don't waste time and sweat. You could post the measurement of wingtip to wingtip and state that if this measurement is not right, it needs to be fixed. I went with Etrailer because in the past you've been very informative and helpful. (I could have gotten it at Amazon 3 days earlier). You just lost a couple stars on my rating list because of this. I'll update this afternoon after trying again. (96 degrees in Florida)

William K.

7/21/2023

Mike L.

8/2/2023

Jerry

9/7/2024

Nick C.

5/31/2023

well my hitch was bent when I got it and when I sent pictures they said forget trying to bend it. They gave me an RMA to return it and shipped a new one the next day. Good customer service.

Mike L.

6/1/2023

John S.

3/6/2023

So, spend hundred of dollars, endure a crap install AND still have to reshape the thing so it will fit? Sounds like a hard no. Sell something of better quality.

Vollie

4/12/2023

Mike L.

4/12/2023

Mike

4/14/2023

Mark

5/2/2023

Cw P.

5/11/2023

Chris R.

5/17/2023

Todd

2/15/2025

Robert

11/20/2022

I am looking for a class 3 trailer hitch for a 2007 Toyota Avalon to support a 2" receiver bike rack I already have. Any suggestions?

David B.

11/21/2022

Helpful Links

William D.

4/15/2022

will a 2022 vw teaguan wire trailer harness fit a 2022 taos. not the splice kind..

David B.

4/15/2022

Amir

4/4/2022

2inch versus the 11/4 inch opening for 2017 Jetta??? Which is recommended. Pros and cons please….

David B.

4/12/2022

Todd M.

10/21/2021

I have a hitch from a 1999 Chevrolet Blazer. Is it possible to mount this hitch to a 1999 GMC Sierra 1500 with the use of some kind of adapter bracket? Thanks

Les D.

10/27/2021

Mark

9/25/2021

Ordered this for my GMC Acadia 2019, per the many recommendations on the website. I've been at this for 3 hours, and I can not install this because the support triangle on the Curt Bar, stops the bumper screws from being able to hold the bumper on. The only solution I can think of is to grind down the Curt hitch but I want to see if anyone has any other solutions?

Les D.

10/20/2021

Ben

7/5/2021

I purchased a trailer hitch for my 2017 Toyota RAV4 and the bolts that came with my trailer hitch kit screws in correctly on the left rear side but the two on the right rear side do not. Can anyone help me out with a solution?

Jon G.

7/7/2021

Helpful Links

Ekrem Z.

3/18/2021

I’m having a hard time finding me a 2” hitch for my 2011 VW Jetta, TDI Sport Wagon. Can you please help?

Joe

7/28/2020

I have a 2008 Buick Enclave and I need to order a Trailer Hitch Receiver along with a Curt Ball Mount for 2" Hitches. I want to be sure what i order. Can you tell me what i would need. I am looking for something simple to pull the lawnmower. Nothing fancy.

Chris R.

5/25/2020

Chris R.

5/28/2020

Kelly K.

5/2/2020

i received my trailer hitch and am satisfied with the overall product but i have one problem the bolts provided for the nuts that are on the vehicle the bolts are too big i cant get them started i have the holes and wire brushed them i believe the hardware needed on this vehicle is 7/16 bolt does that sound correct?

Chris R.

5/4/2020

Tom S.

5/23/2020

Show All (26) Replies

Hide Replies

on Trailer Hitch

Videos

for Trailer Hitch

Help Articles

for Trailer Hitch

Expert Answers

for Trailer Hitch

The difference between the Class II and Class III hitches has to do with their Gross Trailer Weight (GTW), their Tongue Weight (TW), and their Hitch Receiver Size. Class II trailer hitch receivers have a 1-1/4 inch receiver and can be rated up to…

view full answer...Hello Ken, It looks like the measurement for the Curt and the Eco are going to be the same. We have not been able to do the install on the EcoHitch Stealth Trailer Hitch Receiver - Custom Fit - 2" #EH82KR but after reviewing the instructions the…

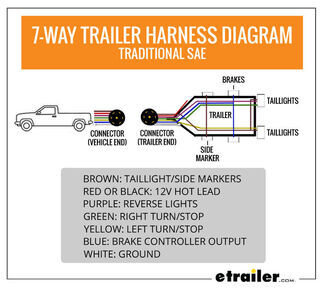

view full answer...A 4-Way trailer connector has the basic lighting functions only; running lights, left turn signal and brake lights, right turn signal and brake lights, and ground. A 7-Way has these functions and a 12 volt circuit, a circuit for electric trailer…

view full answer...If you check out the attached picture you can see it basically sits flush.

view full answer...Hey Ann, it looks like you went with the Curt hitch part #C13397 which is ai confirmed fit for your 2025 Honda CR-V hybrid and will work great for you. Will you be towing with the hitch?

view full answer...Hey Jason, There are a couple hitch options for your 2025 Honda CR-V Hybrid. All 3 are 2" hitch options with a 3,500lb towing capacity and a 525lb tongue weight capacity. These have all been confirmed with the manufacturer to work with hybrid…

view full answer...Yes, they do John. To add a hitch to your 2026 Kia Sportage hybrid, I recommend the Curt item #C94WR. This hitch is custom fit and bolts to your Kia with included hardware. This is a class III hitch with a 2" receiver. It's going to give you…

view full answer...Yes, it does Sarah. The EcoHitch Stealth Trailer Hitch item #EH82KR has been confirmed to fit all models of the 2026 Kia Sportage including the hybrid. This is a custom fit class III hitch with a 2" receiver. It includes all parts necessary to…

view full answer...Hey Charlene! Roadmaster actually does make a base plate for your 2025 Chevy Trax. If you do not have the ACTIV trim level you need the Roadmaster Direct-Connect Base Plate Kit #RM25EQ and if you have the ACTIV trim you need the #RM25DQ. Both will…

view full answer...Hey Christoph, You are definitely making sense with that question asked. With that said the EcoHitch you were looking at, #EH82KR, is not one that we have been able to install on that particular vehicle yet, and I have not had luck with EcoHitch…

view full answer...Hey Scott, thanks for reaching out! Yes, the Curt Trailer Hitch Receiver #C13397 will fit perfectly fine on your 2025 Honda CR-V Hybrid Sport. What are you planning on using the hitch receiver for?

view full answer...Hey Don! Although both fit the 2024 Ford F-350 it is a little more specific. The EcoHitch Hidden Front Mount Trailer Hitch #EH54QR is only designed to fit the F-350 dually while the #EH39CR fits the single rear wheel F-350. Neither will fit if you…

view full answer...Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"In these days of customer "no service" I am usually disapointed when doing business with people I don't know. It was refreshing doing business with you. I'm impressed!"

Pnw S.

7/14/2025

The passenger side mounting tab on my Curt 13505 was slightly bent out of alignment. I found this article and tried the bench vice and 2x4 technique without success. My technique - I put the tab in the 2x2 space of a receiver on my other vehicle. The tab fit easily in the 2x2 space and the 90 degree tab nested well into square shape. This placed the hitch in an upright/vertical position and made it very easy to gently apply the pressure I needed to straighten the tab. After a few gentle outward pulls, framers square indicated the tab was straight again (when compared to the other side). The holes lined up and now the hitch is installed.