Protects the hub by keeping out the water, dust, and debris

Replace dust caps when they're visibly dented, misshapen, corroded, or just missing

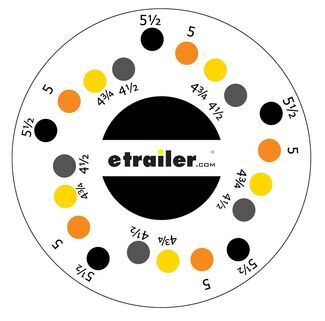

To measure for replacement dust caps, find the diameter of your hub's front bore hole (in inches) to 3 decimal places

Helps keep the components of your hub assembly fixed in place inside the hub

Replace a spindle nut when it's visibly damaged or corroded, or the threads are worn down

If you need to replace a spindle nut, find the diameter and thread pitch of your threaded spindle The inner diameter of your spindle nut should match your spindle's diameter

Round Washers - Used on round spindles, typically with castle nuts and cotter pins D Washers - Used on spindles with a flat side. Can be used with either a castle nut and cotter pin, or a jam nut and nut retainer Tongue Washers - Used on spindles with a groove notched through the thread. Typically used with a castle nut and cotter pin Tang Washers - Come in several varieties (they either have a "tang" that sticks up, or one that sticks in). Can be used on spindles that have a flat side or a groove in the thread. Do not need cotter pins, since the tang keeps the spindle nut from moving

Can protect bearings from being scratched by the spindle nut, and can prevent spindle nuts from turning

Change out spindle washers when they're corroded, scratched up, or mangled

Look for a washer with the same diameter as your spindle, that suits your spindle style

Bearings rotate inside the hub, within their associated races

Select new bearings/ races when the old ones are scratched, pitted, discolored, corroded, and/or misshapen

Look for identifying numbers, check your axle's capacity, and measure the inner and outer diameters of your old bearings

They keep the grease securely inside the hub assembly

Replace grease seals when they are dented, misshapen, corroded, or no longer hold grease

Look for identifying numbers, or measure the diameters of the back hub bore and the spindle

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"I received this order yesterday. Thanks for the outstanding service. I appreciate it! Thanks, Alex"

Alex

Blowing Rock, NC