Trailer Jacks

A trailer jack is an important part of safe towing. If you need to add or replace a jack on a trailer, the following information can help you choose among the many kinds to find the right one.

Basic Functions of a Trailer Jack

- Raises and lowers the trailer so that you can connect the coupler to and disconnect it from the ball on your hitch

- Keeps the trailer level when it's not attached to the tow vehicle

- Stabilizes the trailer for loading and unloading and when the trailer is parked

Go to more information about:

- Trailer tongue weight and height

- Jacks for standard ball/bumper pull trailers

- RV landing gear and heavy-duty jacks

- Jacks to stabilize trailers

- Jack accessories

- Repair parts for jacks

Trailer Weight Capacity and Height

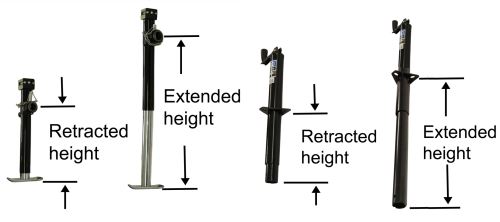

Trailer jacks come in different weight capacities and lengths. Remember to consider the length of the jack in both the retracted and extended positions. When extended, the jack has to lift your coupler high enough for it to clear the hitch ball on the vehicle. And the jack has to retract far enough to clear the ground when you're traveling. The following information can help you find a jack with the proper weight capacity and length for your application:

1. Determine the Height of a Jack

To determine if a jack will work for your trailer, you'll need to know its height, both retracted and extended. These dimensions are usually given for jacks. They're taken from the bottom of the jack (including any foot that may be present) to the mounting point. The mounting points can vary, depending on the style of jack. Standard A-frame jacks are usually measured to the bottom of the mounting flange. Pipe mount jacks are measured to the center of the mounting pipe. Jacks that have a bolt-on bracket are usually measured to the centerline of the bracket.

2. Trailer Tongue Weight

Trailer tongue weight (TW) is the downward pressure that the coupler places on the hitch ball. Typically, TW is 10 to 15 percent of your gross trailer weight (GTW), which is the weight of the trailer when it is fully loaded. For example, a 5,000-lb trailer has a TW of 500 lbs to 750 lbs pressing down on the ball.

- Choose a jack with a capacity that matches or surpasses your TW

- If you are unsure of your TW, you can view our tips on towing a trailer page for more information on how to weigh your trailer tongue. The Sherline trailer tongue weight scale can greatly simplify weighing your trailer's tongue.

- Because of manufacturing processes and costs, many jacks of different sizes and weight capacities are similar in price. So you can use a jack that will easily surpass your trailer's TW yet won't be too large or expensive. For example, you could use a 2,000-lb jack for a 3,500 GTW utility trailer, even though the estimated TW would be around 525 lbs.

3. Trailer Tongue Height

- With the trailer level and parked on level ground, measure the height from the ground to the bottom of the trailer coupler

- The jack should extend about 4" higher than the level height of the coupler so you can raise it over the ball for connecting and disconnecting the trailer

- The jack should retract enough to be shorter than the coupler height of the level trailer

- It should also retract (or pivot out of the way) enough to clear the ground when the trailer is being towed. To make sure the jack will clear uneven ground, the higher it retracts, the better.

Jacks for Standard Ball/Bumper Pull Trailers

A-frame Trailer Jacks

- A-frame jacks conveniently bolt or weld onto A-Frame couplers or sit in a brace behind the coupler

- Capacity: 2,000 lbs to 5,000 lbs

- Applications: A-frame utility, camper and landscape trailer applications

- Manual crank or 12V-powered models available

- Manual crank jacks come in one of two styles - cranking from either the side or the top

- One type may work better than the other depending on the clearance around your trailer

- Manual crank jacks come in one of two styles - cranking from either the side or the top

- Drop-leg style available

- Saves time when raising and lowering

- Simply pull the pin on the leg to lower the inner leg and the foot to the ground

- Line up the holes on the inner and outer leg and reinsert the pin to lock the inner leg in the lower position

- Crank the jack to extend it and raise the trailer (Because the inner leg and foot are close to the ground, you won't have to crank the jack much to raise the trailer)

- Saves time when raising and lowering

- Allows for greater lift

- Many models of A-frame jacks let you add the wheels or feet of your choice to best fit your application

Side Mount Trailer Jacks

Side-mount jacks either bolt or weld to the side of the frame of a pole tongue or A-frame trailer. The pivoting design lets the jack swing up and out of the way for towing and down for jacking. Manual crank jacks come in one of two styles - cranking from the side (most common) or top. One type may work better than the other depending on the clearance around your trailer.

Three mounting styles for side mount jacks:

1. Pull-Pin Swivel Trailer Jacks

- Pull-pin swivel jacks clamp on or weld to the trailer frame

- Clamp-on style fit frame sections up to 3" wide x 5" tall

- Weld-on style can mount to frame in any convenient location

- Capacity: 800 lbs to 1,500 lbs

- A pull pin holds the jack in position - simply pull the pin to release the jack and change its position

- The pin is spring loaded so that it will automatically snap back in when the jack reaches the stow or jack position

- Lightweight marine trailers frequently use these kinds of jacks, which are often zinc coated for extra resistance to corrosion that salt water can cause

- Typically a wheel is included to make it easy to manuever the trailer

2. Pipe Mount Trailer Jacks

- Pipe or tube is welded to the trailer frame, providing a mount for the jack to pivot on - down for jacking and stabilizing, and up for towing

- Weld-on mounting method gives you more options for where you can mount the jack

- Capacity: 2,000 lbs to 7,000 lbs

- Mounting location is frequently on the trailer's tongue, but often found at the sides of the trailer near the back to aid with stabilizing and leveling

- Detent pin holds jack in up or down position

3. Drop-Leg Trailer Jacks

- Drop-leg jacks are either welded or bolted to the side of your trailer's tongue

- Clamp-on-style drop-leg jacks will usually fit a frame up to 3" wide x 5" tall

- Capacity: 8,000 lbs to 12,000 lbs

- Applications: agricultural, industrial and construction trailers

- Square cross section offers improved side-load strength over other designs

- Drop-leg feature makes for fast leveling and increased lift

- Saves time when raising and lowering

- Simply pull the pin on the leg to lower the inner leg and the foot to the ground

- Line up the holes on the inner and outer leg and reinsert the pin to lock the inner leg in the lower position

- Crank the jack to extend it and raise the trailer (Because the inner leg and foot are close to the ground, you won't have to crank the jack much to raise the trailer)

- Saves time when raising and lowering

- Some models can be paired up with a follow jack and used as landing gear on RV trailers

- Motors can be added to some models as an option

- Both their high capacity and the ability to be paired with a follow jack make these jacks an attractive option for gooseneck and fifth-wheel trailers

RV Landing Gear and Heavy-Duty Jacks

- RV landing gear and heavy-duty jacks mount with brackets to the sides of the trailer frame

- Supports a portion of the trailer's weight

- Capacity: 6,000 lbs to 12,000 lbs (Some have a much higher capacity.)

- Landing gear jacks frequently come in pairs

- You can also buy a drop-leg jack and add a follow jack

- Double tube drop-leg design

- Manual crank or 12V DC powered

Jacks to Stabilize Trailers

Fifth Wheel and Gooseneck Stabilizing Tripod Jacks

- Supports trailer at the king pin or gooseneck hitch

- Stabilizes trailer front to back

- Built with wide footpads to prevent sinking and tilting

- Capacity: 1,200 lbs to 5,000 lbs

- Sets up quickly and stows away when you're traveling

- Available in steel or aluminum

Light-Duty Stabilizing Jacks

- Bolts onto trailer frame, folds up for storage and pulls down for use

- Typically located at the back or corners of the trailer

- Capacity: 300 lbs to 1,000 lbs

- Works well for small utility trailers and pop-up campers

- Stabilizes trailer for loading or whenever you move around on it

Scissor Jack Stabilizing Jacks

- Bolts or welds onto trailer frame

- Operates by screw gear (also called worm gear) and handle

- Typically located at the back of the trailer

- Capacity: 300 lbs to 3,000 lbs

- Usually sold in pairs with a combined capacity of 5,000 to 6,500 lbs

- Stabilizes and levels bigger campers

Pipe Mount Trailer Jacks

- Pivots around a tube that is welded to the trailer frame

- Capacity: 2,000 lbs to 7,000 lbs

- Mounts on the trailer's tongue or on the sides of the trailer near the back to aid with stabilizing and leveling

- Comes in one of two styles - cranking from either the side or the top

- One type may work better than the other depending on the clearance around your trailer

- Held in up or down position by detent pin

Slide-out Supports

- Supports slide-outs on camping trailers

- Protects RV frame and extension tubes

- Adjust by means of threaded rod or, for fast setup, combined sliding and threaded rod

- Capacity: up to 10,000 lbs

- Usually sold in pairs or as a set of 4

Electric- and Manual-Adjust Stabilizer Jacks

- Supports and levels trailer

- Bolts underneath trailer frame

- Available in electric- and manual-adjust models

- Capacity: up to 6,000 lbs

Leveling System

- Automatically levels your 5th-wheel

- Bolts to 4 corners of trailer

- Controlled remotely for convenient operation

- Automatically positions your trailer for hookup by means of memory feature

- Capacity: 20,000 lbs (5,000 lbs per jack)

Slide-in Camper Jacks

- Raises and lowers your slide-in camper for loading and unloading

- Eliminates need for permanently installed jacks

- Supports camper on L-shaped lift brackets

- Breaks down into 3 pieces so you can easily transport it

- Operates by hand crank

- Capacity: 3,000 lbs per pair

Camper Step Stabilizer Jack

- Supports camper steps

- Increases stability of steps

- Takes strain off of camper's frame

- Adjust by threaded rod to fit a range of step heights

- Capacity: up to 750 lbs

Trailer Jack Accessories

Jack Stabilization Accessories

Jack Feet

- Helps stabilize trailer and spreads out the load on the jack over a larger surface

- Keeps jack from sinking on soft ground

- Can be used for extending jack height

- Attaches with pin or "twist-lock" mount

- A twist-lock makes it easy to take the feet off to increase ground clearance during travel

- Many jacks have a permanent foot

Other Jack Accessories

Casters or Wheels

- Allows you to more easily maneuver loaded trailers into hitching position

- Attaches with pin or twist-lock mount

- A pin or twist-lock makes it easy to take the wheel off to increase ground clearance during travel

- Always take off a removable wheel for travel

- A pin or twist-lock makes it easy to take the wheel off to increase ground clearance during travel

Wheel Chocks

- Keeps a trailer from rolling or slipping when it's parked

- Some wheel chocks can function as an instant jack on tandem axle trailers

- Steps to use chock as a jack:

- Set the chock in front of one of the trailer's tires on the side that you want to raise

- Pull the trailer forward

- The chock will tilt, raising the trailer's tires off of the ground

- If the trailer has two axles, the tire that is not supported by the jack, but that is on the same side of the trailer, will also be raised so that it can be changed

Repair Parts and Kits

Trailer Jack Gears

- Provides an economical alternative to replacing an entire jack

- Matches by manufacturer and production year (a date code should be stamped in the outside tube near the bottom of the jack)

- Not available for all makes and models

Jack Handles

- Replaces broken, bent or lost handles

- Available to fit most jacks

Replacement Mounting Brackets

- Provides an attachment point for jack on trailer tongue

- Allows mounting onto I-beam or channel with no overlapping bolts or straps

- Available in weld-on and bolt-on styles

- Designed to fit specific makes and models of jacks

Written by: Raymond P.

Last updated: 7/5/18

Sky T.

10/1/2021

I just purchased the Lippert power stance jack with the aux cord to power from my truck as I am using it on my landscaping trailer (no battery). Install was fine, however, it seems I am not getting power to the Jack? I know I am getting power from the 7-pin on the truck as i have a breakaway battery box with LED display that reads it is charging that battery. Truck is a 2019 F150. I even pulled the aux cord end apart to ensure that it was wired correctly to match 12v from the truck and it is. Thoughts?

Robert C.

9/26/2021

I need a 5 K top handle for an A frame tailor that is the shortest between the mounting plate and the top of the jack so my tail gate will not hit it. About 8".

Storm B.

8/4/2021

My tube jack is welded on my trailer and has rusted or fused in some way so I can't raise or lower my trailer. Can I take apart the tube jack or is there some way to remove the old one in order to replace it

Jeff

5/15/2021

I have a Haul-master 2 wheel jack. I think I over shot, my trailer isn’t heavy enough to turn the wheels when empty. CanI convert it to a single wheel?

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"Nice shopping experience. Good selection and prompt shipment. After I see the products in person, I am sure that I will be back for more. Best, Jim"

Angela B.

1/18/2022

I currently have a hand crank jack for my 2006 travel trailer and would love to see if it can be upgraded to an automatic one.