To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

The Tekonsha P3 is a brake controller beloved for its reliability and useability. You're able to save your settings and multiple profiles. It's easy to install, and with the custom harness, it's plug-and-play.

Features:

Specs:

Braking output is the maximum amount of power that will be applied to your trailer's brakes. How much braking output you need is determined by the weight of your trailer; a heavier trailer will need more power to bring it to a stop. You want to go as high as you can without the trailer brakes locking up.

Use the arrow buttons on the front of the module to set the output.

The boost setting controls the aggressiveness of your trailer's braking, meaning how quickly the brakes reach the maximum braking level. If your vehicle takes too long to come to a stop, increase the setting. If it stops too abruptly, decrease the setting.

Depending on the level of boost, your trailer brakes can start at either 13 percent or 25 percent of the set braking output. So instead of starting at 0, the brakes will start at 25 percent and get to 100 percent sooner. This keeps the trailer from pushing your tow vehicle forward.

Boost Levels:

| Approximate Gross Trailer Weight | Boost Level | Increase in Initial Power Output |

|---|---|---|

| Less than tow vehicle GVW | B1 | 13% |

| Equal to tow vehicle GVW | B1 or B2 | 13% or 25% |

| Up to 25% more than tow vehicle GVW | B2 or B3* | 25% |

| Up to 40% more than tow vehicle GVW | B3* | 25% |

*Both B2 and B3 offer a 25-percent boost in initial power. But the braking curve for B3 is more aggressive than that of B2. This means that, even though you will start out with the same intensity when using these boost levels, you will get an overall more aggressive braking experience with the higher level. So if you use B3, you will reach maximum braking sooner than if you use B2.

To engage the manual override, twist the rotary-style lever from right to left. This will activate the trailer's brakes and brake lights independently of your vehicle, great for stopping sway or controlling your trailer's momentum in an emergency.

The P3 is able to store your settings in multiple profiles so that you can have them ready to go for different trailers and drivers. Even the display is super customizable: you can change the screen color, brightness, and language to make it easy to use.

The P3 makes it easy to troubleshoot problems as they come up, with comprehensible and detailed diagnostics displayed on the screen.

Diagnostic troubleshooting messages include:

Diagnostic warning signs include:

The Prodigy P3 offers advanced safety features to prevent damage to various components of your towing setup.

-Integrated reverse battery protection shields the brake controller and your trailer's breakaway system from shorts.

-When the P3 is not in use, it draws only 3.6 milliamps, minimizing drain on your vehicle's battery.

-Any time your vehicle and trailer are at a standstill with the brakes applied for more than 5 seconds, the hold feature will kick on and reduce power to just 25 percent. This will keep your trailer in place without your brakes overheating.

Installing the P3 is incredibly simple. You'll mount the bracket to your dashboard then mount the unit to the bracket. Plug the custom harness into your vehicle and into the unit. Done!

Keep in mind that the P3 must be horizontally level and parallel with the direction of travel to work correctly.

With a replacement wiring harness (sold separately) and replacement bracket (TK5906 - sold separately), you can even transfer the Prodigy P3 to another vehicle.

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake controller installation kit (ETBC7 - sold separately).

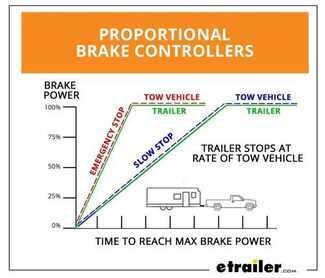

Proportional braking means that your trailer brakes mimic your tow vehicle's brakes. If you slam on the brakes, your trailer brakes will activate with the same intensity; if you brake lightly, your trailer brakes lightly too. The trailer's braking is in proportion to your vehicle and trailer.

The Prodigy P3 uses an internal inertia sensor to detect how your vehicle is braking so it can send the right amount of braking power to your trailer. It measures the inertia of your tow vehicle and activates the trailer's brakes to slow at the same rate. The result is uniform braking across your towing setup. No push-pull action - just smooth, proportional braking every time.

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

When it comes to choosing a brake controller, a lot of them are gonna look very much the same. And two of them that I really like are from Tekonsha. We have the Prodigy P2 and the Prodigy P3. So, they look very similar, but they do have quite a few differences and we're hoping to break that down, that way you can decide which one's best for you. Here we have our P3 installed and really it comes down to it has more bells and whistles than the P2, otherwise it's pretty much the same controller. The P3 does have a nicer/easier to use display.

It's a little bit more user friendly. It uses some icons here that, you know, show you a trailer and that way you know pretty quickly what boost level you're at and it's really easy to read. It's a nice digital display and you can change a lot of that. Also, it has a little bit more diagnostics. So as far as, instead of just having error code with the P2, this one will actually tell you exactly what it is and there's a host of diagnostics so that way you can look at it.

You won't have to troubleshoot the code by looking at the owner's manual. It'll tell you right away what's happening. The P3 is also really nice if you have a bunch of trailers in your fleet, you can set up presets, up to five of 'em, and that way when you hook up to said trailer, you can select that and it's gonna be preset to the boost settings and also the gain that you may have dialed in. That way you just hook up and you'll be ready to go. Multiple trailer settings are gonna be nice, especially if you have a work truck and you're hooking up to a bunch of different trailers, you can get that dialed in, but if you tow the same trailer over and over, or you know that you're only gonna have one trailer long term or maybe two, that's really not gonna be a function that is necessary.

Now with the P2 installed, you can see right away that the display is obviously not as fancy as the P3, but you again have all the same functionality. There are less buttons, so that kind of keeps it simple. If you just need a brake controller, this is a great option. You still have your power knob, you have your boost button, and you still have essentially the same manual override, which I do like on the Tekonshas, you have a nice modulation here. But really when it boils down to it, they are very, very similar.

The size is gonna be almost identical. They're gonna mount up the same, they're gonna install the same. Again, you have that same proportional here. They both work for one to four axles. They're both proportional. So pretty much the same thing, just more bells and whistles on the P3. If it's something that you're gonna wanna keep for a long time on your vehicle, a P3 is pretty sharp. I do like the display, and something to think about too, you can always take a brake controller from one vehicle to the next, so, but if you're just need to tow a trailer and you need a brake controller, P2 you're not gonna go wrong with. I just like the fact that there is diagnostics that are a little bit more straightforward with the P3. And if you're worried about if it's gonna work with your trailer, they're both gonna work with the same kinds of trailers. You can have electric brakes, you can have hydraulic brakes, it doesn't matter. These are gonna work with either one. So hopefully this video helps break down some of the similarities and differences to help you decide which Tekonsha Prodigy Brake Controller is gonna be best for your needs.

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.