To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

This stout brake controller has easy controls, with the buttons up-front and easy to reach, and the manual override a simple slide lever. The digital display is large, simple, and easy to read. Included harness lets you just plug right into your BMW.

Features:

Specs:

Power output is the maximum amount of power that will be applied to your trailer's brakes. How much braking output you need is determined by the weight of your trailer; a heavier trailer will need more power to bring it to a stop. You want to go as high as you can without the trailer brakes locking up. It adjusts on a scale of 0 to 10.

Once you have the power output set, you can fine-tune your braking by adjusting the sync control. This controls the aggressiveness of your trailer's braking, meaning how quickly the brakes reach the maximum braking level. If your vehicle takes too long to come to a stop, increase the setting. If it stops too abruptly, decrease the setting. The sync setting is shown as a number followed by the letter "o" to differentiate it from the output reading. The least aggressive sync setting is 0o and the most aggressive is 9o.

The Activator IV displays the power settings as you adjust them. While braking, the unit will display the power output setting. To see or adjust the sync setting, step on your brake pedal and press either the plus or minus button to increase or decrease the setting.

The display will also show trouble codes to alert you to any potential problems, such as short circuits or overloads, or if there is an internal problem with the controller.

Installation

Because inertia plays no role in the functioning of this controller, you do not have to mount the unit at any particular angle. Your mounting options are limitless, so long as you can still easily access the controller and manual override. And because the included wiring harness is custom fit for your vehicle, you can just plug the controller in. No cutting or splicing needed!

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake control installation kit (ETBC7 - sold separately).

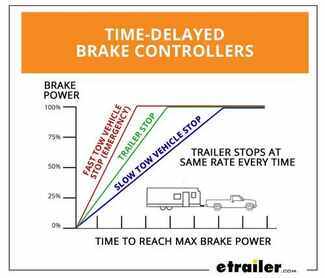

Time-delayed braking means that when you apply the brakes in your vehicle, the controller activates the trailer brakes at a pre-set intensity and rate. Both the amount of braking power (gain) and rate of application (load) can be adjusted to suit your preference, the road conditions, the type of trailer, and the weight of your load. To determine which levels are best for your application, test your towing setup and choose what feels right.

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Speaker 1: Today on our 2016 Dodge Grand Caravan, we're going to be taking a look at and showing you how to install the Draw-Tite activator IV trailer brake controller for one to four axles, part number 5504. Now we're also going to be using in conjunction, pigtail wiring harness for the Draw-Tite brake controller and that's going be part number 7894. We're also going to be using the no drill long bracket, which is going to be part number 18136. Also, to help us get the wiring installed, we're going to be using the universal installation kit for trailer brake controllers, part number ETBC7.Here's what our brake controller looks like fully installed. Now this is a time delay brake controller, so we do have the option to mount it pretty much any which way we want. It does have the manual override button right here, which is going to be a lever style.

As you can see, if we start moving the lever over and we max it out, our maximum number's going to be 10 and the minimum number will go down obviously to zero. Now we do have several different options of how we're going to adjust our brakes and how our trailers going to act. For instance, our gain here we're going to have a plus and a minus button and that's going to be the maximum output available for the trailer and 10 being the highest and it's going to go all the way down to zero.If we have it set at 10, that's going to be the maximum power that can go out to our trailer and it's going to me maxing out at that. Now over here on the other side, the sync button has another plus and minus symbol. It's going to start out at zero and we can go all the way up to nine.

What that's going to do is, if I leave my setting at nine and my gain on 10, when I press on the brake it's going to very quickly ramp up to the maximum power. Then it'll apply the maximum amount of brakes to it. Now if I turn my sync setting down to zero, it's going to very slowly ramp up, as you can see here.Now this is going to be nice because we're going to be able to fine tune our brakes and on our trailer and when they're going to react. The display is going to stay off until we push on the brake. Now if we unhook our tester and we're just driving normally and we don't even have anything hooked up to the back.

If we press on the brake, we'll see a red dot in the center and that's letting us know that there is no trailer connected and there's nothing connected at the back.To begin our installation, we're going to need to find a suitable spot to mount our seven way connector. Now to help us mount our connector, our kit does provide us with a seven way connector. But we are going to have to mount this bracket. We're going to be using a long bracket to mount it right here against the hitch. Now this bracket's going to mount using this hose style clamp.

We're going to undo it, that way we can wrap it around our hitch, put our bracket in place, then we're just going to take that clamp and wrap it around. Once we get it wrapped around, we're going to feed it back through the end with our screw, so we can start tightening it up. Now coming back I'm going to be using a 5/16 socket to tighten up that screw.Just want to verify that the clamp's nice and tight but you don't want to overtighten it and break the strap going around. Now we can take our seven way bracket and the screws provided with our long bracket here. We can line up the holes, we're going to drop our hardware down. Once we have the screws in place, I'm going to come back and they provided us with some locking nuts and I'm going to put those in hand tight for right now. I'm going to come back with a 10 millimeter socket and tighten up the nuts on the bottom. Now we're going to take our seven way connector and I'm going to slide my wires into the big portion and then slide it into position, lining up the holes on my plug with the holes on my bracket. Then we can take the provided screws from our kit and we can start sliding them through going all the way through the connector and the bracket itself.Now on the backside, we're going to take some locking nuts again and we're going to loosely secure them down. Now I'm going to take an 11/32 socket and a flathead screwdriver and I'm going to tighten down all my hardware. We can go and start making our connections. Now we already have an existing four pole wire on our vehicle and you are going to need one to get your brake controller and all the other wiring installed. We're going to take our two four pole ends and they're going to meet together. But before I connect them, I'm going to take a little bit of dielectric grease and I'm going to put it inside my connector. That's just going to help with some of the corrosion build and any moisture from getting inside. We can take our two connectors, connect them together and since this is going to be a semi permanent connection, I'm going to wrap it with some electrical tape also to help keep out some of the moisture.And just to make sure our connection's not going to come apart, I'm going to take a zip tie and I'm going to tie it around the two four poles to help keep it more secure. Our wires already have some butt connectors pre-installed on them. Well I'm going to take these off and I'm going to be replacing them with some heat shrink connectors since they are going to be on the outside of the vehicle. I'm just going to cut the ends off and I'm going to strip back the wire. With the wire stripped back, we can insert the wire into our butt connector and then crimp it into place. Giving it a nice little tug to make sure it crimped down and we'll repeat that for our blue wire as well.Now we're going to have our white wire with a ring terminal attached and that's going to be our ground wire. We're going to need to find a clean metal surface to attach this to. Now I'm going to be taking one of the provided self tapping screws with a 3/8 socket and I'm going to attach my ground wire right to the bottom right above my hitch here. Now we should have a purple, a black, and a blue wire. Now the purple wire we're not going to be using in our application. That's going to be for your reverse signal to your trailer. We're just going to tie this up but our blue and black wire, we're going to need to take the gray sleeved wire and we're going to be connecting it to here. As you can see on the inside of this gray sleeve, we're going to have a black and white wire. Now we're going to need to cut this back, so we can gain access to each of our individual wires inside.I'm going to put it on this hard metal surface to help stabilize it a little bit. Then I'm just going to take my knife and gently cut just the gray insulation back far enough, so that I can peel it back and get access. Now we're going to strip back both ends of our wires. Our white wire we're going to attach to the butt connector that's going to our blue wire. We're going to take it, insert it into the butt connector and then we can crimp it in place. And our black wire we're going to be attaching to the butt connector connected to our other black wire. Give a nice little tug to make sure it's secure. I'm using a heat gun to shrink down my butt connectors. But I do want to mention if you're using an open flame such as a lighter or torch, you want to be extra careful not to burn the wires or char the connector itself.Now our gray wire that we just attached our black and blue wire, we're going to have to run this the length of the vehicle up the front of the engine bay. Now everybody's going to do a little bit differently, just want to mention that you always want to stay away from any moving parts or anything that's going to damage the wire or any heat sources like the exhaust. I'm going to go ahead and run my wire and tie these up and I'll show you how I did it. I bundled my excess wires right behind my bumper here and just tied them up, so they're not visible. Then I went over my hitch, came along the back of my vehicle on the driver's side, cut over went over my rear axle here, went down along the side of the fuel tank. Continuing along zip tying it along the way and then right here I followed my emergency brake cable, zip tying it to it. Then finally I have it stopping right here because we're going to need to go up to the engine and drop something down, so we can get the wire up there.I'm going to take a piece of air line tube that I had lying around and I'm going to start feeding it down my engine til comes out the bottom where my wires are. Now I just want to mention you want to be extremely careful of any heat sources or anything moving because you don't want it to destroy the wire. We're going to send this down. I'm going to make a small loop here just so it doesn't fall down and I don't lose my air line tube. We're going to go back underneath and we can grab our wires. Here's where my air line tube came out. Now I'm going to take my wire and I'm going to make sure that it goes around this post here, so I don't have to worry about it snagging on anything and I'm going to attach my wire to my air line tube with a little bit of electrical tape. That way I don't have to worry about it falling off.Now we can go back up top and start pulling it through. When we pull our wire up, we're going to want to make sure that we get all the wire we can and it's never a bad idea to peak underneath and double check and make sure it didn't bunch up and cause it to not be able to come up. We can go ahead and remove the air line tube from the end of our wire and we can start mounting our breakers and making our connections. Now we're going to need to split the insulation off of our two cables here and we're going to need to back as far as we can. Or in this case, we're going to need to go all the way to right about where the firewall is. I'm going to make a small incision in the middle of the gray insulation and you want to be careful not to pierce either the black or white wire on the inside.I'm just going to take my time splitting the insulation open and then peeling it back little by little. Once we have the insulation peeled back, we can go ahead and cut off the excess and we can start bringing our attention to the black wire. Now our black wire is going to be providing power to our seven way. We're going to install a 40 amp breaker in between our seven way connector and the battery itself. We're going to mount our breaker right here on the firewall. Now since we're going to mount it here, I'm going to estimate about how much wire I need to reach my breaker. Then I can cut the excess off.Now I do want to mention you want to hold onto the extra black wire that we just cut off because we will be reusing it. We can go ahead and strip back the end of the black wire. You take one of the provided ring terminals and we're going to be using the smaller of the two ring terminals in our kit and we're going to slide it over our wire we just stripped. Then we can crimp it into place. Now before we mount our breaker, I want to bring your attention to the two posts. One of them is going to be silver and one of them is going to be a copper color. Now underneath the post there's going to be very small letters. One is going to say AUX for auxiliary and one is going to say BAT for battery.The wire coming from the back, it's going to go to the silver post or auxiliary. Then in between our battery and the breaker, we're going to have another wire connecting to the copper post. We're going to be taking a few self tapping screws, we're just going to screw directly into the firewall right here. Since this wire's coming directly from the back, we're going to remove the nut that's on the silver post or the auxiliary post. We're going to slide our ring terminal on and then replace the nut. I'm going to come back with a 3/8 socket, I'm going to tighten up that nut. We're going to take that excess wire that we just cut off. I'm going to estimate about how much I'm going to need to get from my breaker to my battery post. Then I'm going to cut it right there.Now we're going to strip back both ends of our wire. We can go ahead and grab a couple more of those ring terminals and we're going to put one on each of the wire we just stripped. Now on the other end of the wire, we're going to take one of our larger ring terminals and we're going to crimp it into place. Now we're going to take the small ring terminal and we're going to put it on and secure it to our breaker that has the copper post. For right now, I'm just going to leave this loose. I'm going to leave this end of the wire loose as well. We'll be hooking that up later on. Now if you remember our white wire here is connected to the blue wire at the back of our seven way.Now that's going to be for our brake signal, so we're going to send this white wire into the cabin of our car. Now if you can look closely back here, you're going to see a rubber grommet and that's where we're going to be going through. But since it's a little hard to reach out here, we're going to go to the inside of the car and see if we can get it from there. Here's where that grommet is on the inside. Now since it is restricted in area, so it's going to be a little hard for you to see while I'm working. I'm going to tell you what I'm going to do. I'm going to cut the grommet and pass my air line tube through, that way we can do the same process we did to get our wires where we needed to get them.Here I'm going to take my air line tube that I sent through my firewall and I'm going to take that white wire. I'm going to put a little bit inside my air line tube to help secure it down. I'm going to take a small amount of electrical tape, wrap it around to help secure it when I start pulling it through. Then we can go back to the inside and start pulling our wire. This is the same thing. We're going to want to make sure that we pull all the slack out and if need be go back in the engine to make sure it didn't get bound up or not allowing it to come all the way through. We can go ahead and remove the tape and the air line tube from our wire.Right here we're going to have our brake controller harness and the wire that we just ran into the inside, again is connected to the blue wire at the back of our seven way. This is going to be for our brake output signal. I'm going to estimate about how much wire I'm going to need. If I mount my brake controller in this general location, this should be plenty of wire to connect everything and still have room to work with. I'm going to cut my white wire and I'm going to strip back the end of it. Now again hold onto the excess white wire because we are going to be reusing it. With the end stripped back, I can go ahead and take another one of my heat shrink butt connectors and crimp it into place. We can take the end with our blue wire and it's already pre-stripped. We just go ahead and insert it into the butt connector and crimp it down.Now for the rest of our wires on our harness, we're going to start out by paying attention to our white wire. Now our white wire is going to be for our ground and we're going to have to ground it directly to the battery. I can already tell you, I don't think this is enough wire to get out to the battery all the way. I'm going to take another one of my yellow butt connectors and I'm going to attach it to the end of my white wire and on the other end, I'm going to take the excess piece of white wire that we cut off and strip the end and attach it to there. This way we'll have plenty of wire to get out the ground on our battery. For the black wire, we're going to do the same thing. This is going to be our power for our brake controller.Now this is where I hope you kept the black wire that we had excess because we're going to be attaching it here and sending it out back to the firewall. Again I'm going to take my air line tube and I'm going to poke it through the grommet underneath the dash, so that I can start pulling my black and white wire out to the engine bay. To get through my grommet, I'm going to take a flathead screwdriver. I do want to mention you want to be extra careful when doing this. But I'm going to poke a hole through the grommet and there is two layers. You're going to poke through the initial layer and you want to be careful not to break or pierce any of the wires. That's why I'm going towards the outside of the grommet here.Once I get through one layer, I'm going to keep poking through until it goes all the way through both layers. We're going to pull as much of our wire out as we can, get all the excess slack out. Now as I mentioned before, our white wire is going to be for our ground. I'm going to estimate a rough amount of about how much I need and then I can cut it off and strip back the end. Now we can grab one of the larger ring terminals in our kit and we can crimp it onto our white wire. Now I'm not going to connect this just yet, but this eventually is going to connect directly to the negative post on the battery. For now we can bring our attention to the black wire. Now again we're going to have to mount another breaker. We can estimate about how much wire we need. We can mount one right here. We're not going to need too much, so we can go ahead and cut back this wire and strip back the end of it.Now the end of this wire, we're going to be attaching one of the small ring terminals in our kit. I'm going to be using the 20 amp breaker because our Caravan here is not going to be towing a trailer with more than tow axles. Now if you are going to be towing a trailer with more than two axles, you're going to want to put the larger of the two breakers in. We can take the black wire coming form our brake controller harness, I'm going to remove the nut that's on the silver post of my 20 amp breaker. I'm going to install it on the post and reinstall the nut.Now we're going to need to take that excess black wire that we had before again and we're going to estimate about how much we're going to need to go from our breaker to the battery. We can cut our wire and we're going to strip back both ends and apply one small ring terminal and one large ring terminal on the other end. Now we can take the small ring terminal and come to the breaker with the copper post. Put the small ring terminal in place and then resecure the nut. Again this wire will be going to the positive post of the battery but right now we're not going to connect it. We're going to need to go back inside and make one more connection.We should have one wire left on our brake controller harness and it's going to be the red wire. Now where we're going to connect this is going to be to the cold side of the brake switch. What I mean by cold side, is that it's only going to have power or a signal when the brakes are applied. I have my test light here that I'm going to test my wires that are attached to my brake switch. We're going to have to go under the dash, find where the connector is attached to the brake switch and we're going to have to test each one of those wires. Now I already did trace my wire down and I found a little bit easier spot to test it at and you might be able to see a little bit easier as well. It's going to be this white wire with a green stripe on it. The way we're going to test it, is you're going to make sure that your ground on your test light is good. Then we're going to poke it and as you can see I'm not getting any signal right now. But if I push the brake, the signal comes on.That's going to be the wire that we're going to need to use. Now it is still in kind of a rough area, so I'm going to cut this wire and I'm going to have to make a few connections. I'm going to cut my wire in half. Then I'm going to need to strip back both ends of this. Now our red wire is going to connect in between our two brake switch wires. What I'm going to do is, is I'm going to take a butt connector and I'm going to take two of the wires, the red wire and my brake switch wire. Then I'm going to attach it to one of my butt connector. Then the other end of my brake switch wire on the other end of the connector. This is going to be a little bit difficult for you to see because I'm going to have to get in here, but I'll show you what it looks like when I'm done.Here's our connection that we made. I'm going to come back and shrink down my connector. Now both wires that are coming off of the battery side of our breaker, we're going to be attaching directly to the positive post of our battery. We're going to need to remove that nut that's holding it in place. Now I'm going to be using a 10 millimeter socket to remove it. If you have any other accessories or any other electronic components plugged in there, you want to make sure that you leave them plugged in or that you reinstall them once you get everything else in place. Then we need to reinstall the nut. Now our ground wire we're going to be attaching to the negative side of our battery. Again I'm going to be using a 10 millimeter socket to remove the nut. Slide our ground wire over it and then reinstall the nut. With a 3/8 socket, I'm going to come back and make sure all of my breaker terminals are tight and start tidying up all my wires.We're going to need to find a suitable location to mount our brake controller itself. It does come with a bracket and some self tapping screws. I think I'm going to mount my bracket right here, so that my braking controller will sit right below my ignition and that way it's out of the way of my legs. But I can still gain access to it right here. Now there's no specific orientation or anything that you have to mount this but we're going to try to make it as level as we can, just so it looks nice. We'll notice that we have a couple small holes on the side of our brake controller and that's where those screws are going to be going into place. We're going to take it and we're going to slide it to where it lines up with the holes on our bracket here. Then we can take our screws and going through the bracket, go into our brake controller.Now I'm just going to get these set hand tight for now. Just so I can get them in place. Then I'm going to come back and using a quarter inch socket, I'm going to tighten these up because I don't want to use a power drill or any power tools because I don't want to tighten it too far and damage any of the internal components. Now since of the clearance issue, I am using a quarter inch ratchet wrench to tighten this side bolt. What we decided to do is we're going to actually route our wires behind our panel here. If we come to this section just right below the black, right underneath the steering column where it's tan. We can gently just start pulling away. I'm actually going to slip my wires behind there and then I'm going to put it back in place, so I can tilt my brake controller back down. You just want to make sure you don't get your wires stuck in any of the clips and you want to be able to access it so we can plug it back in.I'm going to just reach up, grab our harness, and connect it to the other one. I'm going to route it towards the top where my other plug is. Now unfortunately you're not going to be able to see it because the plug is behind the dash here. We're going to have to go off of feel and make sure that it feels like it's locked into place securely. Now all we have left to do is tidy up all our wires and make sure all of our connections are tight. I'm just going to bundle these wires together. Then I'm going to zip tie them up under the dash, so that way they're out of the way of my pedals. Also I want to mention for our grommet here, since we did have to cut it. I am going to come back with a little bit of silicone and help seal it up. Just tie up our wires to some existing wiring and tuck it out of the way.I got my tester hooked up to my seven way connector and we're going to be checking the lights as well as the brake controller to make sure that it's sending out the correct current and voltage. I'm going to go ahead and run up to the cab and start running off through all of my lights. If I turn on the headlights, you'll see that we have our clearance lights, and our left turn signal, right turn signal, brakes. You can see the brake starts sweeping and ramping up. We know our brake controller's working properly as well as the brakes and the left turn signal and the right turn signal. It looks like everything's good and we're ready to hit the road. That'll finish up our look at the Draw-Tite activator IV trailer brake controller for one to four axles, part number 5504 on our 2016 Dodge Grand Caravan.

Worked great!

It plugged in and worked as advertised,Thank you so much,

Fantastic brake controller. Even better website.

Great controller, we install it on almost every system we do.

Good overall product. Meets needs and is inexpensive.

this controller is great. etrailer delivery, packaging, pricing were ALL great...

Love it.... Installed in my 2011 chevy in about 5 min and it works great. Recommend to anyone

Love the digital display! Digital display is now a requirement when I order a brake controller. It is amazing how much better brake control I have knowing before hand how much brake will be applied.

Works great, very easy to use, and very easy to install thanks

The item appears to be well made and as expected. I'm having some difficulties, but with my camper, not with the unit.

Probably not a really useful review.

Very easy to install. Works very well. I like the digital number readout to show power level being applied to brakes.

Top notch products,Service and Customer service help line.

You guys know your stuff.

Thank you so much for the help everything went flawless and works perfect.

Thank you so much.

Terry

Installing this into my 2005 Tahoe was a breeze. If you just follow the directions and check out etrailers videos you should have no problem. I went from a small popup to a bigger hybrid so I had to get the EBC system. This sure beats taking it to the RV or Dealer store and paying retail plus labor. Thanks etrailer.com

Easy to install. simple instructions, I have it wired up but just have not towed anything yet to get the settings set for my application.

Quality product. The video of how to install clinches the deal. Setup instructions worked perfectly.

Nice product, easy to useEasy to use an upgrade from my Activator I unit. Has the same manual brake control that failed on the Activator I unit. Hopefully this one does not fail.

thank you for the fast delivery ,and for the easy installation vid

was a breeze,ty

Great Product, VERY Easy to install. The only thing I would change is the length of the pig tail. The short length of the pigtail limits your options of product placement.

Great prices, quality products, great customer service and reasonable shipping!!!

ordered on a monday afternoon, received my order on wed after 3 pm...everything was in good condition..these are really good people...thank you so much for the fast service......max

Easy installation works great, great pr ice

Installed in Frontiier quickly with no problems,us the recommended adapter .Good product,quick shipping and great company to work with.

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.