Fastway e2 Weight Distribution w/ Sway Control - Round - 6,000 lbs GTW, 600 lbs TW

- All Info

- Reviews (175)

- Q & A (0)

- Photos

Fastway Weight Distribution Hitch - FA94-00-0600

- 500 lbs

- Fits 2 Inch Hitch

- WD With Sway Control

- Allows Backing Up

- Fastway

- Includes Shank

- Round Bar

- Top-Mount

- Fits 3 Inch Frame

- Fits 4 Inch Frame

- Fits 5 Inch Frame

- Fits 6 Inch Frame

Fight back against winding roads and strong wind gusts that cause your trailer to get squirrelly. This system evenly spreads out your tongue weight for a smoother ride. Hitch ball sold separately.

Features:

- Evenly spreads out your tongue weight among all the axles of your tow vehicle and trailer

- Levels out your ride to restore control and stability

- Lets you tow to the max capacity of your hitch

- Sway control keeps your trailer from getting pushed off course

- Holds your trailer in line with rigid, frame-mounted brackets

- Uses steel-on-steel friction to combat any sway that occurs

- Comptible with surge-type brake actuators

- Desired head tilt is achieved using stackable washers

- Add or remove washers from the spacer rivet in the hitch head

- No-drill, clamp-on brackets can be adjusted along your trailer frame

- Accommodates frame-mounted items such as gas tanks, battery boxes, tool boxes, or generators

- Grease zerks make maintenance easy

- Powder coated steel is durable and corrosion resistant

- Includes head assembly, adjustable shank, spring bars, brackets, handle, and necessary hardware

- Hitch ball sold separately - requires 1-1/4" diameter shank

Specs:

- Fits: 2" x 2" trailer hitch receivers rated for use with weight-distribution systems

- Tongue weight: 400 lbs - 600 lbs

- Maximum gross towing weight: 6,000 lbs

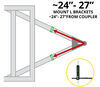

- Sway control bracket positioning: 24" - 27" back from center of coupler

- Maximum trailer frame height: 6"

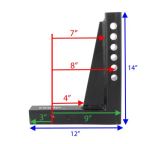

- Shank length: 12"

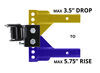

- Maximum rise: 5-3/4" from top of hitch receiver opening

- Maximum drop: 3-1/2" from top of hitch receiver opening

- 10-Year warranty

| Included w/ FA94-00-0600 | Required - Sold Separately | Optional Add-Ons |

|---|---|---|

|

| n/a |

Pro Tip: Before you invest in a weight distribution hitch, make sure your cargo is evenly loaded in your trailer to keep the weight balanced. If you still have a hard time even after balancing your tongue weight, a weight distribution hitch should help.

L-Brackets vs. Add-On Friction Sway Bars

- L-brackets that hold spring bars in place provide a tried-and-true method of sway control

- Provides weight distribution and sway control in one system

- Ensures steady towing, but can be noisy

- Friction sway bars can be added to a standard weight distribution hitch to force your trailer back in line

- Has to be removed at times (e.g. in the rain or when you're backing up), but its adjustable tension is a plus

- Doesn't work with surge-type actuators

If you've got a moderate amount of sway behind you when you tow, and you want to save a few hundred bucks on getting a more premium option like an Equalizer or the B&W Continuum - which you know would be overkill for your application anyway - the Fastway e2 might be the middle of the road option you're after. It creates a rigid system of steel bars and L-brackets that rub together to create friction, which prevents your trailer from getting off track behind your tow vehicle. And it uses friction to force your trailer back in line if a strong crosswind or passing truck is a bit too much for the rigid hold to handle on its own.

Because the steel-on-steel friction of the bars and L-brackets is noisy, don't be alarmed if you hear some banging, creaking, and grinding. It's just the system working to correct sway.

Fun Fact: Steel-on-steel friction is what locomotives use to keep multi-ton railcars from swaying.

Adjusting the Head Tilt

- Adding washers adds tension, but it's not a case of "the more the merrier"

- Stacking washers can be a pain, but you only need to do it once, or if your tongue weight changes

To adjust the tilt, simply slide washers onto the spacer rivet and insert it into the head assembly. Once the spacer is in place, tighten the shank bolts to secure the head to the shank. To check if your truck and trailer are level, you'll need to hookup and release your tongue jack. Repeating this step means adding more washers if the rear of your truck is sagging, or removing washers if too much weight has been distributed to your tow vehicle's front axle.

While the washer-stacking method allows you to fine-tune the setup at the time of installation, it's going to require some patience. It can be time consuming because, if you don't get everything right the first time (which, you probably won't), you'll have to take the head unit apart to adjust the washers. You might have to raise or lower the L-brackets too to get the tension just right, and that's a bit of a pain also. Not to mention that you might have to repeat this process if your tongue weight changes or if you swap out your tow vehicle.

Pro Tip: For a step-by-step guide on how to fully install the e2, check out our videos at the top of this page. Our installers even have some advice to offer on measuring your vehicle's squat.

Why Use a Weight Distribution Hitch?

- Prevents uneven tire wear on your vehicle and trailer

- Keeps the rear of your tow vehicle from sagging

- Lets you tow to the max capacity of your trailer hitch

- Stops your headlights from pointing up at the sky

- Gives you control over steering your rig

Selecting the Right Weight Distribution System

- Think "Goldilocks"

- If you go for overbuilt, you'll have a rigid ride

- If it's not strong enough, it's virtually useless

- Let your tongue weight be your guide

Your tongue weight is the first thing you need to know when figuring out which weight distribution system you need. Most people think that if they get the highest-rated system possible, it'll be smooth sailing. But actually, this will create a rigid ride and a bouncing trailer. On the other hand, if the system isn't strong enough, it won't be able to distribute the weight properly, making it virtually useless.

Once you know your trailer's tongue weight, add it to the weight of the cargo behind the rear axle of your tow vehicle. Then just choose a weight distribution system rated for that combined tongue weight.

94-00-0600 Fast Way e2 Weight-Distribution Hitch - Round Bar - 6,000 lbs

Installation DetailsCalifornia residents: click here

Customer Satisfaction Score:

97% were satisfied with this product

3% of customers were not satisfied

- Product did not meet expectations

- Wrong item was ordered

- Did not arrive in time

Ratings & Reviews

4.7

175 reviews

I received the package on time but the box was destroyed

Works great on my 25 tt

works great

Item as described great quality

Great product and very easy to assemble.

Received quick and great people to work with

Everything went great. Thanks for all your help.

Order agent was very helpful and new what he was selling. Hitch was setting on my door step in 3 days. Very happy with weight distribution hitch.

good to go

Great hitch

Can’t really say much the hitch was recommended by the dealer I got my RV from and y’all had a great price.

Works very well and easy to put together. Huge difference it the way the unit pulls.

Performs well! Pleased with the hitch! Would highly recommend!

Still works great! No sway at all. Great purchase.

See what our Experts say about this Fastway Weight Distribution Hitch

- Choosing Between A Fastway Weight Distribution System With Round Bars Or Trunnion BarsOne of the major differences between a round bar system and a Trunnion bar system is if ground clearance is an issue, you may be better off choosing a Trunnion-bar system simply because these bars slide into the weight distribution head instead of inserting into it from the bottom, thus maintaining a more streamline system.The round-style spring bars slide up into the head and are held in place with clips. The round bar on # FA94-00-0600 extends about 2-1/2 inches below the weight distribution...

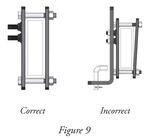

view full answer... - Troubleshooting Fastway e2 Weight Distribution With Movement in L BracketsThe bolts that hold the L brackets for the Fastway e2 Weight Distribution w/ 2-Point Sway Control - Round - 6,000 lbs GTW, 600 lbs TW # FA94-00-0600 need to be torqued to a specific setting which you can find in your installation instructions (as well as the linked instructions on this page). If you haven't torqued them specifically then that would explain why things are slipping. You also need to be sure that the brackets are square with the trailer frame during the installation. The...

view full answer... - Equal-i-zer Weight Distribution for Trailer that Weighs 3,500 lbFor your trailer that weighs 3,500 lbs the Equal-i-zer kit part # EQ37060ET would be a really great option that has a tongue weight range of 200-600 lbs.

view full answer... - Should the L-Brackets On a Fastway e2 Weight Distribution System Move Back and ForthThe l-shaped brackets you are referring to on a Fastway e2 Weight Distribution System like part # FA94-00-0600 should not move back and forth. If they do move back and forth then you will need to make sure they are torqued correctly (75 ft. lbs.) and that they are the correct distance back from the coupler (no more than 30").

view full answer... - Recommended Weight Distribution System For 2017 Dodge Durango Towing a 22.8 Foot Cobalt 226For your Cobalt boat and trailer, I recommend you go with the Fastway e2 Weight Distribution w/ 2-Point Sway Control - Trunnion # FA92-00-0800. This system will give you a stronger system that will also allow you greater ground clearance. This system will handle much better for you as you travel down the road as well as when you are loading and unloading. The sharp angles won't be a problem with this system. This system is easy to engage and disengage as needed, so you will have options....

view full answer... - How to Upgrade the 6,000 lbs Fastway E2 Weight Distribution System to a 10,000 lbs OneHey Justin! The only thing you need to purchase to upgrade the 600 lbs TW Fastway e2 Weight Distribution item # FA94-00-0600 are the 1,000 lbs TW Replacement Round Spring Bar for Fastway e2 Weight Distribution Systems item # FA94-02-1099. What kind of trailer did you upgrade to?

view full answer... - Recommended Drop Shank for Fastway e2 Weight Distribution SystemThe Fastway e2 Weight Distribution w/ 2-Point Sway Control # FA94-00-0600 will allow you to use the Fastway e2 Weight Distribution Shank # FA92-02-4214 to get the extra clearance you desire without compromising the capacity at all.

view full answer... - Recommended Fastway Weight Distribution For 2017 Jayco Jay Flight 195RB TrailerFor your 2006 Buick Rainier and your 2017 Jayco Jay Flight 195RB, the Fastway e2 Weight Distribution w/ 2-Point Sway Control - Round - 6,000 lbs GTW, 600 lbs TW # FA94-00-0600 may be sufficient, however, I recommend bumping up to the # FA94-00-0800. This system will give you the same minimum tongue weight, but will allow for up to an 800 lb tongue weight. Based on the specs for your trailer, if you were loaded to capacity you could have a trailer tongue weight of up to 525 lbs, and that...

view full answer... - Everything Needed for 2019 Ford RangerHi Mike, what exactly are you looking for? You looked at a weight distribution hitch (WDH), are you trying to find the right one for your setup? If you are, can you tell me more about your trailer? To find the right WDH it is important to know the tongue weight of your setup. For example, the Curt TruTrack 2P Weight Distribution System # C69JR you looked at is designed for 800 lbs - 1,000 lbs of tongue weight. If you can add this information in the comments below I can see what the best...

view full answer... - Weight Distribution Hitch For Boat Trailer With Pole TongueHey Steve! You're already on the right track with the Pole-Tongue Adapter for Equal-i-zer Weight Distribution Systems # EQ95-01-5950. This is exactly what you need to install a WDH on your boat trailer. Go ahead and measure 27" - 32" back from the hitch ball to make sure you have room to install the adapter. Also, if this is an aluminum trailer I recommend checking with the manufacturer to make sure it can handle using a weight distribution hitch. Equal-i-zer makes one of the best systems...

view full answer... - Dimensions of Fastway Replacement Round Spring Bar Arms for Fastway e2 Weight Distribution SystemsAll of the Replacement Round Spring Bars for the Fastway e2 Weight Distribution systems, # FA94-02-1099, # FA94-02-0899, and # FA94-02-0699, measure 31-1/2 inches long. The diameter of the bar at the upper end is 1.39 inches, and the inside groove measures 0.91 inches. I have attached a photo showing these dimensions for you. The spring bars differ based on their tongue weight capacities. The construction of the bars determines their weight capacity, rather than the size of the bar. These...

view full answer... - Recommended Weight Distribution System for a 4,500 lbs Trailer For your 4,500 lbs trailer, I recommend the Fastway e2 Weight Distribution w/ 2-Point Sway Control item # FA94-00-0600. This system has built in sway control that will keep your trailer in line with your truck when you're going down the highway and get passed by a semi or make a sudden move. It does not include a hitch ball so you'll want to get the 2" Hitch Ball for Equal-i-zer Weight Distribution Systems Item # EQ91-00-6080.

view full answer... - Comparison of Fastway and Equal-i-zer Weight Distribution Systems for 3,000 Pound TrailerBoth the Fastway # FA94-00-0600 and the Equal-i-zer # EQ37060ET are rated for 600 pounds tongue weight which once your trailer is loaded and you factor in any weight in the back of your 2016 Chrysler Town and Country that is right where you want to be. A couple of differences to consider, the Fastway does not include a hitch ball, but of course you can purcahse either a 2 inch, # EQ91-00-6080, or 2-5/16 inch, # EQ91-00-6100. Also, and the biggest difference, is that the Equal-i-zer uses...

view full answer... - Recommendation for Fighting Trailer SwayIf you are wanting to use a Friction Sway Control Kit, like part # 83660, then all you will need is the Reese Sway-Control Bracket # RP26003 for your 2 inch ball mount. As convenient as the price of a sway control kit is, I highly recommend going with a Weight Distribution (WD) system instead. Not only will it ensure that your towing setup is level, but it will also have an integrated sway control that allows you to back up, unlike the kit. When you choose a WD system you will want to...

view full answer... - Choosing a Fastway e2 Weight Distribution System for 550 TWIf you fully load your trailer and find it has a tongue weight of 550 lbs and towing weight of 6,200 lbs, then ideally you should choose a weight distribution system's where your tongue weight sits middle-road of the system's capacity. As for a Fastway e2 option, the Fastway e2 Weight Distribution 8,000 lbs GTW, 800 lbs TW - Round Bar # FA94-00-0800 is a good option. This system has a described tongue weight capacity of 400 lbs - 800 lbs, and your 550 lbs is just slight below halfway on...

view full answer... - Weight Distribution Recommendation for 2021 Forest River Surveyor Legen 240BHLEFor your 2021 Forest River Surveyor Legen 240BHLE the best weight distribution with sway control is the Reese Strait Line part # RP66083 which has a tongue weight range of 400-800 lbs and features the only sway control that works to fight sway before it starts.

view full answer... - Replacement Adjustment Pin And Washers For A Fastway e2 Weight Distribution HitchHi Shawn! Is this for the Fastway e2 Weight Distribution w/ Sway Control - Round - 6,000 lbs GTW, 600 lbs TW # FA94-00-0600 you purchased back in 2020? If so, we have the Replacement Hardware Kit for Fastway e2 Weight Distribution Head - Round and Trunnion Bar # FA92-02-9600 that includes those pieces, but they are not sold individually, unfortunately. You will end up with a few extra pieces, but hey, now you have a few spare parts! : ) If you are needing this for a different weight...

view full answer... - What Weight Distribution Hitch Should I Get for My 19 Foot Travel Trailer with Dry Weight 3600 PoundHello John, The Fastway e2 Weight Distribution w/ Sway Control - Round - 6,000 lbs GTW, 600 lbs TW # FA94-00-0600 is an excellent weight distribution hitch! I prefer systems that use bars and brackets over those with chains, they just work better in my opinion. When selecting the correct weight distribution system, it’s most important to choose one that closely matches your loaded tongue weight. Since your 19 ft travel trailer has a dry weight of 3,600 lbs, the GVWR is likely between...

view full answer... - Recommended Weight Distribution System for a Lance 1575 Travel TrailerHey Martha! The 8K Blue Ox TrackPro item # BLU47FR is going to be quite a bit overrated for your Lance 1575 travel trailer. I recommend going down in capacity and using the 6K Blue Ox TrackPro item # BLU36FR instead. This system works best with trailer's that have tongue weights between 200 lbs - 600 lbs, which is exactly where your Lance trailer is going to be. If you have any additional questions feel free to throw them into the comment box below.

view full answer... - Will Reese Round Bar Weight Distribution 49913 Work for a 3,700 lb Camper?Hey Brent! The Reese Pro Round Bar Weight Distribution w/ Sway Control # RE44FR (part 49913) is a great option if the 3,700 lbs of your camper is with it being empty. If you're talking about that being the GVWR though, this system will be rated too high and your towing experience will be stiff. For the 3,700 lbs being the GVWR I recommend going with the Fastway e2 Weight Distribution w/ Sway Control # FA94-00-0600 and Hitch Ball # C40030 instead so you get the right amount of performance...

view full answer... - Can Trailer Valet 5X Be Removed When Towing For Using a Weight Distribution Hitch? Yes, you can completely remove the Trailer Valet 5X Swivel Jack and Trailer Mover # STC-V211 when not in use. This is typically the way I prefer to travel with the jack since it so large and it will also help keep it clean from road debris. Since the box does stick out you may have trouble using a Trunnion # FA92-00-0600 style weight distribution as these bars tend to run in line with the frame rails. If you have a Round Bar # FA94-00-0600 this should be fine since the bars hang below...

view full answer... - Can Fastway e2 Weight Distribution be Upgraded from 600 lb Spring Bars to 800 lb or 1,000 lb BarsYes, you can upgrade your Fastway e2 Weight Distribution with 600 lb spring bars to either 800 lb bars or 1,000 lb bars. The right replacement will depend on if you have the Round Bar Fastway e2 # FA94-00-0600 or Trunnion Bar Fastway e2 # FA92-00-0600. The round bar replacements come in a quantity of one, so you would need to order two of the bars, while the trunnion bars come in a pair. For your larger Grand Design 23BHE with a GVWR of nearly 7,000 lbs I recommend the 1,000 lb bars. 1,000...

view full answer... - Recommended Weight Distribution Hitch for Somerset E3 Pop Up CamperThat answer you looked at is a bit confusing and I think it gave you the wrong idea about weight distribution. A weight distribution hitch should not be selected based on your tow vehicle. The most important thing is making sure your loaded tongue weight falls into the tongue weight range of the hitch. I don't know what year or exact model you have but I'm guessing 268 lbs is the dry tongue weight. You will need to measure to see what your loaded tongue weight is, or at least find the...

view full answer... - Will an Equal-i-zer Shank Work with a Fastway E2 Weight Distribution System Yes, the Equal-i-zer Weight Dist Shank part # EQ90-02-4900 will work with the Fastway E2 weight distribution system such as the Fastway e2 Weight Distribution w/ 2-Point Sway Control part # FA94-00-0600. As long as the 10" of rise and 6" of drop will maintain a level towing angle between your 2017 Ram 2500 and trailer, this weight distribution shank will work well for you.

view full answer...

Do you have a question about this Weight Distribution Hitch?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.