Tekonsha Prodigy P2 Trailer Brake Controller w/ Custom Harness - Up to 4 Axles - Proportional

Arrives before Christmas

Arrives before Christmas

with factory Tow Package

Will this fit?

To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

- All Info

- Reviews (2750)

- Q & A (0)

- Videos (6)

- Photos

Tekonsha Trailer Brake Controller - TK68ER

- Electric

- Electric over Hydraulic

- Proportional Controller

- Up to 4 Axles

- Tekonsha

- Under-Dash

- Plug-In

- Under-Dash Box

- Single Trailer Only

- LED Display

The Tekonsha P2 is a classic brake controller you know you can rely on. It's easy to install, and with the custom harness, it's plug-and-play.

Features:

- Proportional - Smooth, safe, and good for your brakes long-term

- Fast installation - Mount the bracket to the dash and then attach the unit to the bracket

- Plug-and-play - Custom harness included

- Simple controls - Thumbwheel for gain, button for boost, and manual override lever

- Easy-to-read screen - Large, simple, and dims automatically

- Safe - Built-in safeguards protect vehicle, trailer, and controller

- Quick disconnect - Easy to unplug and remove the controller when you don't need it

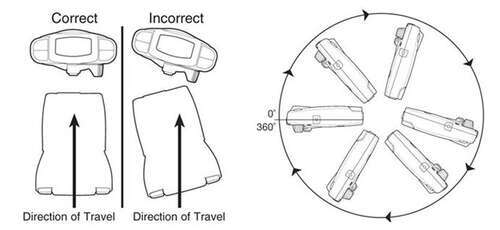

- Automatic leveling - Must be parallel with direction of travel and horizontally level

Specs:

- Application: trailers with up to 4 axles (8 brake assemblies)

- Compatible with electric or electric-over-hydraulic trailer brakes

- Dimensions: 5-1/8" long x 3-1/8" wide x 2" tall

- Mounting: 360 degrees vertically

- Warranty:

- Limited lifetime on brake controller

- Limited 1-year on wiring harness

Gain Adjustment

Gain is the maximum amount of power that will be applied to your trailer's brakes. How much braking output you need is determined by the weight of your trailer; a heavier trailer will need more power to bring it to a stop. You want to go as high as you can without the trailer brakes locking up.

You can adjust the gain by turning the thumbwheel on the front of the controller.

Power Boost for Heavy-Duty Towing

The boost setting controls the aggressiveness of your trailer's braking, meaning how quickly the brakes reach the maximum braking level. If your vehicle takes too long to come to a stop, increase the setting. If it stops too abruptly, decrease the setting.

Depending on the level of boost, your trailer brakes can start at either 13 percent or 25 percent of the set gain. So instead of starting at 0, the brakes will start at 25 percent and get to 100 percent sooner. This keeps the trailer from pushing your tow vehicle forward.

Boost Levels:

| Approximate Gross Trailer Weight | Boost Level | Increase in Initial Power Output |

|---|---|---|

| Less than tow vehicle GVW | B1 | 13% |

| Equal to tow vehicle GVW | B1 or B2 | 13% or 25% |

| Up to 25% more than tow vehicle GVW | B2 or B3* | 25% |

| Up to 40% more than tow vehicle GVW | B3* | 25% |

*Both B2 and B3 offer a 25-percent boost in initial power. But the braking curve for B3 is more aggressive than that of B2. This means that, even though you will start out with the same intensity when using these boost levels, you will get an overall more aggressive braking experience with the higher level. So if you use B3, you will reach maximum braking sooner than if you use B2.

Manual Override

To engage the manual override, twist the rotary-style lever from right to left. This will activate the trailer's brakes and brake lights independently of your vehicle, great for stopping sway or controlling your trailer's momentum in an emergency.

Safety Features

The Prodigy P2 offers key safety features to prevent damage to your towing setup:

- Integrated reverse battery protection shields the brake controller and your trailer's breakaway system from shorts.

- When the P2 is not in use, it draws only 3.6 milliamps to minimize the drain on your vehicle's battery.

- Any time your vehicle and trailer are at a standstill with the brakes applied for more than 5 seconds, the hold feature will kick on and reduce power to just 25 percent. This will keep your trailer in place without your brakes overheating.

The Prodigy P2 also runs continuous diagnostics to check for problems as they come up, including:

- Open ground

- Overload

- Output short

- Power loss

- No trailer connection

Installing the Tekonsha P2

Installing the P2 is incredibly simple. You'll mount the bracket to your dashboard then mount the unit to the bracket. Plug the custom harness into your vehicle and into the unit. Done!

Keep in mind that the P2 must be horizontally level and parallel with the direction of travel to work correctly.

With a replacement wiring harness (sold separately) and replacement bracket (P7685 - sold separately), you can even transfer the Prodigy P2 to another vehicle.

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake controller installation kit (ETBC7 - sold separately).

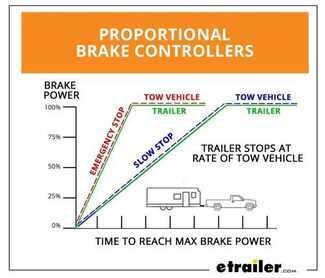

What is Proportional Braking?

Proportional braking means that your trailer brakes mimic your tow vehicle's brakes. If you slam on the brakes, your trailer brakes will activate with the same intensity; if you brake lightly, your trailer brakes lightly too. The trailer's braking is in proportion to your vehicle's braking. This saves wear and tear on the tires and the brakes on both your vehicle and trailer.

The Prodigy P2 uses an internal inertia sensor to detect how your vehicle is braking so it can send the right amount of braking power to your trailer. It measures the inertia of your tow vehicle and activates the trailer's brakes to slow at the same rate. The result is uniform braking across your towing setup. No push-pull action - just smooth, proportional braking every time.

90885 Tekonsha Prodigy P-2 Proportional Brake Controller - 1 to 4 Axles

Replaces Tekonsha 90185

307300 Tekonsha Brake Control Wiring Adapter with 2 Plugs

Replaces Tekonsha 3073-P

Installation DetailsCalifornia residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Install: Tekonsha Prodigy P2 Trailer Brake Controller on a 2004 Jeep Wrangler

Today, on our 2004 Jeep Wrangler, well be installing the Tekonsha Prodigy P2 Brake Controller, part number 90885 in conjunction with the Etrailer Brake Controller install kit, part number ETBC7. Using the hardware and bracket provided, we can secure the 7-pole bracket to the new 7-pole connector. The 7-pole connector will have both a four flat and seven blade trailer connection points. Well that bolts and nuts provided to secure the 7-pole bracket to our new 7-pole. Now, as we have our fasteners installed finger tight, well go ahead and run them down to secure the bracket.Next, we can go ahead and take the bracket and secure it directly to the hitch-mounted bracket. Now that our 7-pole is secured to the hitch, we can start connecting our wires.

Before I connect any of my wires, I'm going to go ahead and tape up a portion of our 7-pole pigtail here just to help bundle the wires up and protect them. Using some black electrical tape, Ill go ahead and put it around the pigtail. Note, this is also inaudible 00:01:48 you can use the wire loom thats provided with the install kit. Next, well take the 4-pole plug thats already been installed under the vehicle. Bring it down to our 7-pole where we can connect the two flat-pole connectors together.

Ill go ahead and remove the cap because itll not longer be needed.Then before I make that connection, were going to use some dielectric grease between the two connection points to help prevent corrosion over time. Well be using the Edelmann Dielectric Grease, part number 11755 and then make my connection. We can take the purple wire used for trailer reverse lights. It will not be hooked up in this application so were going to go and cut it short, but its long enough that if we need to, we can go back and add to it to connect the trailer reverse lights. Next, were going to attach the gray duplex cable to our black and blue wire leads.

The gray duplex cable has two wires inside. Were going to go and expose them by cutting back a couple of inches of the sheathing. Be careful not to cut the wiring underneath when you split the sheathing. You can peel it back, just cut it off out of the way. Then well go ahead and strip back the two wires.The black wire will connect color-to-color, black-to-black and this will provide the 12-volt hot lead directly to our 7-pole connector.

The other lead will be the blue wire from the pigtail and the white wire from our duplex cable and this will provide power to our trailer braking. Now, once Ive made my connection points back here, I'm going to go ahead and finish wrapping up my electrical lead with some black electrical tape. This will help keep our connections clean from dirt, dust, debris and moisture. Ill get my wire out of the way before I tape it up. Im just going to simply route it up and over the frame, going towards the front of the vehicle and ultimately, up to the engine compartment. I will include the white wire with the pre-attached ring terminal which is going to act as the new ground for our simple connector.Now with our wiring taped up, I'm going to go ahead and take the white wire with the pre-attached ring terminal and secure it directly to the frame. This should provide the ground for our new trailer connector. We can use a self-tapping screw thats provided with install kit to secure the ring terminal. Now, with our self-tappers in place that secured our ground wire, we can go ahead and secure our wiring and start running our gray duplex cable up to the front of the vehicle. Keep in mind, when routing any of your wirings, stay away from any moving components such as inaudible 00:05:15 suspension and excessive heat such the exhaust. As we route the wire, well use the black zip ties provided with the install kit to secure it.Once we finish our routing and securing the wire, well cut off the excess from the zip ties to clean up our install look. Now with our wiring routed here to our engine compartment, were going to use the manufacturers grommet just below the manufacturers wiring harness to route through the grommet and into the cabin of the vehicle. To get through the grommet, were going to use our utility knife and just cut a slice in it. Now weve got a slice big enough to route three wires to it. The white wire from our gray duplex cable we ran from the back of the vehicle thatll ultimately run to the brake control and pigtail then the power and ground for the brake controller.To do that, Ill go ahead and mark our length where its going to route into the grommet. Well use our utility knife to slice the sheathing so that we can split the two wires out separately. Were going to go ahead and cut the gray duplex cable. We only need enough of the white wire to run into the cabin of the vehicle to connect to the brake control and pigtail and the black wire will go to our breaker and then the breaker hot lead will run through the battery. Were going to mount the breaker here on the driver's side in open location. Now, weve got the sheathing split, well go ahead and cut off the sheathing. Taking the white wire, pushing it through our grommet inside then Ill go ahead and secure the gray duplex cable so we dont have to worry about it falling back down and getting tangle up or inaudible 00:07:48 to the exhaust here on the driver's side and where we can mount our two breakers.To mount our breaker, well use a self-tapping screw provided with the brake controller install kit that will go directly here to the sheet metal. For the hot lead that goes to the 7-pole connector, well use our 40-amp breaker. We can take the power wire that we ran, strip back the wiring and then add a small ring terminal and then attach the ring terminal to the silver side of the breaker, as the copper side of our breaker will run directly to the battery. To secure it to the breaker, well use a star washer and nut provided with the install kit. Next, well need to run the lead to put power and ground to the brake controller. I'm going to take the remaining portion of our gray duplex cable, run it across the top of the engine compartment, through the battery, back over to the driver's side.This will allow me to get the length necessary for the ground wire thatll attach directly to the battery at the negative batter post. Once we have it routed, we can go ahead and guesstimate the length thatll need to be run inside to the cabin of the vehicle or the connection to the brake controller pigtail. Ill then go ahead and mark the length as well need to split the black and white wire out from the remaining portion of our gray duplex cable. Now, I'm going to go ahead and pull the wire back out and go ahead and cut the sheathing all the way back across to the battery. Now once we have the sheathing removed, we can go ahead and take the duplex cable end, feed it into the grommet to the cabin of the vehicle and the white wire back over to the battery.Now, the gray duplex cable that we ran inside, weve got the white wire run into the battery and the black power wire will run up here next to the first breaker we mounted to we can mount the second breaker. The second breaker for this application will be the 20-amp breaker in our kit. Well go ahead and mark our length, cut off the excess. Just like we did for the first breaker, strip it back, add a small ring terminal and secure it to the silver side of our breaker. Now, with the majority of our wiring run here in the engine compartment, were going to move to the cabin of the vehicle, taking the wiring that we ran inside, connect it to the brake controller pigtail and mount our brake controller.Now, we moved inside the vehicle, we can see the white wire that we ran from the rear of the vehicle that ultimately will connect to the blue wire on the brake controller pigtail to put power going to the trailer breaking. Inside our gray duplex cable is the black and white wire that we ran from the engine compartment inside for power and ground for the brake controller which will also match color-for-color to the brake controller pigtail. The fourth wire here on our brake controller pigtail is the red wire that gets connected to the brake pedal switch and thatll be the wire that is only hot when the brake pedal is depressed.Lets go ahead and locate the manufacturers wiring that we need to connect to. Using out test light, we can go ahead and put our ground clamp on and then use our test light with the key in the auxiliary position. Well back code 00:13:46 the manufacturers brake switch to find the correct wire to connect to. As you see, we press on the brake pedal and the test light lights up and we know weve connected to the correct wire. Its going to be a light yellow wire with a brown stripe. To connect the red wire from our pigtail to that wire, well use a quick splice connector thats provided with the brake controller install kit. To get our quick splice connector in position, well need to get a little easier access to the wire so were going to use our utility knife to cut away the electrical tape and pull the wire out to gain access to it.Now with the electrical tape pulled out of the way, well take the pale yellow wire out of the bundle where we can get an easy access to it. Then well take the quick splice connector. Slide it over the manufacturers wiring. Now, once we have the quick splice connector in position, well slide the red wire into the quick splice connector and crimp it down. Once weve crimped it down, we can close the clasp. Now that we have the red wire attached, well go ahead and start wiring up our remaining wires. Were going to start with the blue wire which connects to the lone white wire that we ran inside. Again, it came from the rear of the vehicle that we connected the blue wire pigtail on our trailer connector. Using the buck connectors provided with our install kit, we can slide it on to the wire and crimp it down.Going into the other side of the buck connector will then be the blue wire from our pigtail. Now with that connection made, I'm going to go ahead and take the gray duplex cable that we ran for power and ground for the brake controller, cut off the excess cable, strip back the sheathing and then the wiring. Once we have the wiring stripped back, we can add the buck connector for each. Then well take the brake controller pigtail wiring and again, match color-for-color when we make our connections. Now, as I wrap our connection points with some black electrical tape, I'm also going to wrap up the brake controller pigtail wiring thatll help bundle the wires up and give it a cleaner install look. Once we finish wrapping it up, I'm going to leave the brake controller pigtail at this time until after we mount the brake controller pocket.To mount the brake controller pocket, well use the hardware provided with the brake controller here on the passenger's side of the steering wheel, out of the way of the four-wheel drive lever, but within arms reach of the driver in case they need to use it in emergency situation. Now with our pocket mounted, I'm going to go ahead and take the brake controller pigtail, run it up through the pocket and connect it to the brake controller. Once that connection is made, we can then go ahead and set the brake controller in the pocket and secure it. Well take zip ties and secure our wiring up underneath the dash.Now, were finished with our connections on the inside, well move back to the engine compartment. Were going to take the remaining wiring from our gray duplex cable, route it across the engine compartment following the white ground wire that we ran earlier and ultimately, were going over to the driver's side where we mounted the breakers. Once we get over here to the driver's side, well go ahead and take the wiring, strip it back and add the ring terminals. Were going to take each of the leads that we ran from the battery and then install them under the copper side of the breaker. These will be the how leads thatll send power to the breaker then back to our brake controller and 7-pole connector. Once we have the hardware installed, well go ahead and tighten them all down.Now that I have it secured, I can go ahead and secure the wiring that we followed back over to the battery. Now that were over here on the passenger's side, well take the two hot leads that go to the positive battery post, mark the length and cut it off. We can then go ahead and strip them back and add two large ring terminals and then well secure it to the positive battery post. Once we have the ring terminal secured, I'm going ahead and slide them onto the positive battery post bolt and then attach a 1/4 inch nut, adding it to the post to secure the ring terminals. Once we have the ring terminals on and the nut in place, Ill go ahead and tighten them down. Ill finish securing my wiring and our two hot leads are done.Well now go ahead and repeat the same process here for our ground which ultimately runs to the brake controller. With power to the brake controller, well have a single light indicating the power. Then, once we connect our trailer and the trailer braking, the display will show a C indicating that the trailer wiring is connected. Then once were finished using our trailer and we disconnect it, the display will show NC for no connection. There you have it. Weve gone through the install and operation of our Tekonsha Prodigy P2 Brake Controller, part number 90885 in conjunction with the Etrailer Brake Controller install kit, part number ETBC7 on our 2004 Jeep Wrangler. .

Customer Satisfaction Score:

94% were satisfied with this product

6% of customers were not satisfied

- Package not accepted

Ratings & Reviews

4.9

2749 reviews

See what our Experts say about this Tekonsha Trailer Brake Controller

- What is the Difference Between the Tekonsha Prodigy P2 and the P3 Brake ControllersActually, the P3 now has the upgraded axis accelerometer like the P2. The Tekonsha P3 Trailer Brake Controller # 90195, will work with both electric over hydraulic brakes on the trailer as well as electric brakes. It has a menu option on the display that allows the user to switch between the two systems. I have included a link to the installation details for the P3. The P2, # 90885, will also work with both electric brakes and electric over hydraulic brake systems but the mode is selected...

view full answer... - Electric Over Hydraulic Brakes Don't Work w/Brake Pedal on Newer GM Trucks w/OEM Brake ControllerLike you said, many factory integrated brake controllers will not work well with electric over hydraulic trailer braking systems. Some of the newer versions of these controllers now have an electric over hydraulic mode. Check to see if any of your trucks have this mode and, if they do, if the braking starts working with the pedal. Otherwise there are a couple of solutions to solve this issue. First, there may be an adapter that will allow the factory controllers to work but it depends...

view full answer... - Can Brakes be Added to 3,500 Pound Dexter Trailer AxleYes, brakes can be added to your trailer and I've linked an article to help with the parts you'll need. The first thing you'll need is the brake mounting flanges welded to the axle, like you mentioned. The correct flange is # 4-35 however these need to be welded by a qualified welder because the mounting flange must be welded square and concentric. This is generally done using a jig at a trailer shop. I've linked our selection of hub and drum assemblies for 3,500 pound axles. You'll...

view full answer... - Are Electric Trailer Brakes Okay to Use on a Boat TrailerHydraulic brakes are better suited for boat trailers for the simple fact that wires and water do not like to cooperate with each other, but the etrailer.com Self Adjusting Electric Trailer Brakes, # AKEBRK-35L-SA, can be used on a boat trailer assuming there is a 4-bolt brake mounting flange welded to the axle. The compatible right hand brake assembly is part # AKEBRK-35R-SA. If you choose to install electric brakes on your boat trailer, there are a few things that you should keep in mind....

view full answer... - Brake Controller Installation In 2020 Chrysler PacificaGreat question Mark! There is a brake controller plug and play wiring adapter for the 2020 Chrysler Pacifica to plug into the tow package with part # TK93VR. Tekonsha is currently the only manufacturer that has one available that we are aware of. This will plug into the built-in port under the dash of the Pacifica for an easy installation. For the brake controller I recommend the Tekonsha Prodigy P2 Trailer Brake Controller part # 90885. The P2 is one of our most popular brake controller...

view full answer... - Parts Needed to Install Brake Controller in 2014 Honda PilotHey Mike, the 7-way kit part # 118265 does fit your 2014 Honda Pilot to provide it with a functional 7-way but it does not come with the brake controller install port you'd need for a brake controller. So you can hardwire in a brake controller or have a Honda dealer install one for you so that you could use a # 3070-P to install a brake controller like the P2 part # 90885. If you'd prefer to hardwire let me know and I'll walk you through that process as well.

view full answer... - Should Blue Wire From Brake Controller Have Constant PowerThe blue wire coming from the back of your Tekonsha Voyager Brake Controller # 39510 is for brake output to the 7-Way connector. This wire should only have power with the brake pedal depressed or the manual override activated on the brake controller. If you are getting constant power on this blue wire this may be an indication that the controller is bad but there is an easy way to test this. You will want to first sever the blue wire several inches from the back of the controller. Then...

view full answer... - Testing for Proper Voltage on the Brake Output CircuitThere are many things that can affect the voltage on the brake output wire from your brake controller to your trailer brakes such as the power setting on your brake controller, how you are testing the wire and if you are testing it with the brakes or manual override activated. Using a multimeter to test the voltage on the brake output wire at your trailer connector will not always give the proper reading because it does not provide a load on the circuit like brake magnets from a trailer...

view full answer... - Brake Controller Recommendation for a Truck with Air Brakes and a Trailer with Electric BrakesThe trailer brakes work on a separate circuit than the lights. You have a couple of options to control the electric brakes on the trailer. One option is to use an air over electric brake control, # HA100400C. This unit connects to the air brakes on the truck and when the brakes are applied it sends an electric signal back to the trailer brakes. The other option, and what I would do, is to use an electric brake controller like # 90885. For either of these controllers, the red wire attaches...

view full answer... - Fuse Box Instructions for Installing a Brake Controller on a 2003 Chevy SilveradoWhether your 2003 Chevrolet Silverado came with a factory 7-Way or not, the wiring for both the brake controller and the 12V power pin on a 7-Way is already run. If you check out the video I attached of the Prodigy P2 # 90885 being installed on a similar 2003 Silverado you can see what needs to be done with the wiring under the fuse box at the 3:20 mark. You will just need to connect the Blue wires together and you will be good to go since you already took care of the Red wires. The P2...

view full answer... - Brake Controller Has Constant 12V Power But Trailer Brakes Do Not EngageFirst I suggest you double check your wiring from the controller. Typical brake controller wiring is: Red wire goes to the brake switch cold terminal, which gets power only when the pedal is pressed; Blue wire connects to the trailer brake circuit; White wire is ground; Black wire connects to the 12V power source. Please note that we do offer vehicle-specific wiring harnesses that plug into the OEM socket under your dash and provide bare wires on the other end to wire directly to your controller....

view full answer... - Brake Controller Wiring for Ford E-450 MotorhomeIf your vehicle has a factory brake controller plug, you can simply use the Tekonsha Plug-In Wiring Adapter for Electric Brake Controllers – Ford, Item # 3034-P, which will connect to the vehicle plug and the brake controller. On the new E-450 vehicles, the plug is located behind the storage compartment above the radio. Once you remove the storage compartment, you can plug in the adapter and run the cord behind your dash to the brake controller. I've attached several images showing where...

view full answer... - Recommended Brake Controller And Plug-In Harness For 2021 Suburban Z71 With Tow PackageFor your 2021 Chevy Suburban, I recommend going with the Tekonsha Prodigy P2 Trailer Brake Controller - 1 to 4 Axles - Proportional # 90885. This is an easy to use controller that works very well with trailers that have electric brakes like yours. I use this exact one on my vehicle and I love it. You will also need Tekonsha Plug-In Adapter # 3016 which allows you to connect the brake controller to your factory tow package plug. I attached some demonstration videos to help.

view full answer... - What Trailer Wiring is Needed for 2024 Subaru Outback WagonHey Ryan, so I looked up the Aliner LXE and it doesn't look like a trailer that would have brakes so most likely all you need is a 4-way confirmed as a fit for your 2024 Subaru Outback XT like the Tekonsha part # 118467 which installs pretty easily. 4-way trailer wiring basically controls all of the taillight functions on a trailer but nothing else If instead the trailer DOES have brakes you would need to convert the 4-way to a 7-way with the part # ETBC7 so that you can install a brake...

view full answer... - Towing a Trailer with Electric Brakes with a Semi Tractor with Air BrakesTo tow your trailer that uses an RV style 7-way blade style connector with your semi that has a 7-pin connector, you need to construct an adapter that will also combine the brake signal into the right and left directional signal pins. This can be done by using a female 7-pin socket # PK11720 to accept the plug from the semi, a tail light converter # 119178 and a female 7-way RV blade-style socket # PK12-707E. The converter would be wired in between both sockets to combine the brake light...

view full answer... - Troubleshooting Tekonsha Prodigy P2 Brake Controller that Doesnt Recognize TrailerIt's possible the brake controller is bad, but you definitely want to check some other things before you purchase a replacement. The first thing to do is inspect both the truck's and the trailer's connectors to make sure the pins are clean and free of debris. On the trailer connector at the rear of your 2004 Chevrolet Silverado test the pin at the 5 O'clock position with a circuit test like # PTW2993. You'll need someone to engage the manual lever on your P2 for this. If this checks...

view full answer... - Tekonsha Prodigy P2 Trailer Brake Controller Showing OL, PL and SH Error CodesFirst, lets start by resetting the Prodigy P2. With the trailer disconnected from the vehicle, disconnect the brake controller by unplugging the harness from the rear of the unit, and plug it back in. The display will show NC for 15 seconds, and then show two dots. The OL error code indicates that the Prodigy is drawing too much current. This is usually caused by a short on the brake output wire on the trailer or low resistance to ground on the brake wire. Look for any pinch points, or...

view full answer... - Is There a Brake Controller Wiring Adapter for a 2022 Volkswagen AtlasThank you so much for the photos and all of the info! Currently none of our manufacturers have an adapter that they have tested and approved to work with that connector you found on your 2022 Volkswagen Atlas, so you'll have to cut off that connector on your vehicle and use the included pigtail to spliced in the Prodigy P2 # 90885 in your vehicle. You will need to connect the following wires from the pigtail to the corresponding functions on your Atlas: Blue - 7-Way Output to Trailer Black...

view full answer... - How Does a Brake Controller Know when a Trailer is ConnectedWhen a trailer with electric brakes is connected to a vehicle that has a brake controller that brake controller is sensing the draw of the brake magnets by sending back a small amount of voltage on the blue wire. The brake controller also get's signals from the tow vehicle to let it know when you are stepping on the brake pedal. On most vehicles this connection is made either at the brake switch above the brake pedal or through some kind of tow package wiring. I have included a link...

view full answer... - How do I Tell if the Brake Controller is BadYou are correct, you should only be getting output when the brake is applied, or the override switch is activated. It sounds like the controller might be bad, but to make sure, you should probably bench test it before tossing it. Use a circuit tester, and check the red wire that exits the rear of the controller. This wire should only go hot when the brake pedal is pressed. If this checks out ok, then the controller is bad and must be replaced. We have a video that shows how to bench...

view full answer... - How Does Brake Controller Install in 2017 GMC Canyon For installing a brake controller in your 2017 GMC Canyon there is no plug present under the dash, but the needed wires are already run. You will connect the brake controller wiring with the vehicle wiring already present under the dash. It's up above the brake pedal. If you check out the attached video link you can see the Prodigy P2 part # 90885 installed in a similar GMC Canyon and you can see exactly where the wiring is and the entire install process.

view full answer... - Installing a Brake Controller on a 2000 Chevy SilveradoThere are some connections under the hood that will need to be made to complete the installation of the Tekonsha P2 Brake Controller # 90885 with Wiring Harness, # 3025-P. Once you have plugged in the # 3025-P harness into the port to the left of the brake pedal, you can make the connections under the hood. Locate the power distribution box. There will be a bracket on the driver side near the windshield that will need to be removed. Remove the bracket and power distribution box cover....

view full answer... - Brake Controller Installed in 2021 Chevy Silverado Z71 Trail Boss Not Powering UpAssuming that you've found the correct connector for the # 3064-P brake control harness which is located under the dash to the left of the steering column, I'd wager than you have a fuse missing in the power distribution box in the engine compartment on the passenger side. Check fuse location # 84, and make sure that there's a fuse installed there. If the fuse is missing or blown, you can obtain a replacement from your local auto parts store.

view full answer... - Brake Controller and Install Wiring Needed for 2014 Jeep Wrangler UnlimitedSince you have a 7-Way you will only need a few more components to complete a brake controller install on your vehicle. First let's start with a brake controller. I would recommend the Prodigy P2 Brake Controller part # 90885. This is our best selling brake controller because of how well it works and how easy it is to set up. Next, for a wiring kit to install the brake controller to the 7-way you would want the Wiring Kit for 2 and 4 Brake Electric Brake Controllers # 5506. This will...

view full answer... - Custom Brake Controller Adapter for a 2024 Jeep Wrangler w/ the Tow Package Yes, we do! To connect your Prodigy P2 Brake Controller item # TK68ER to your 2024 Jeep Wrangler JL Rubicon with the tow package you'll need the Tekonsha Custom Wiring Adapter item # 3073-P. The plug you're looking for is located underneath the dash, to the left of the steering column, taped to another harness near the emergency brake pedal.

view full answer... - How Long is Tekonsha Brake Controller Install Harness 3073-PHey Denis, the length of the Tekonsha brake controller install harness part # 3073-P is 34 inches. Is that long enough?

view full answer... - How Do I Install A Brake Controller On My 2022 Jeep Wrangler Unlimited With The Factory Tow Package?Having the factory towing package on your 2022 Jeep Wrangler Unlimited will actually make life a lot easier. You will need a couple parts to get the Redarc Tow-Pro Elite up and running, but it's easier than you think. The Redarc Tow-Pro Elite is also a controller I recommend a lot as it will have one of the cleanest looks once install, if not the most. It also works very well and is the controller I would put in my Silverado if I ever needed one. With that said, all you need is some wiring, First,...

view full answer... - Is There a Brake Controller Harness for 2020 Jeep Gladiator With Factory Tow PackageThere are brake controllers with a wiring harness for a 2020 Jeep Gladiator with the factory tow package, with each of the brake controllers using the Tekonsha Custom Wiring Adapter for Trailer Brake Controllers - Jeep # 3073-P. - Good: Brake EVN # TK63VR - Better: Tekonsha Prodigy P2 Trailer Brake Controller # 90885 (Good LCD display, 360 degree vertical mounting) - Best: Tekonsha Prodigy P3 Trailer Brake Controller # 90195 (Best LCD display, storable settings, diagnostic checks & troubleshooting) If...

view full answer... - Parts Needed to go From 4-Way to 7-Way for Brake Controller on 2018 Jeep JL Wrangler RubiconWe can absolutely get you the right parts to add a 7-way and brake controller with your 2018 Jeep Wrangler Rubicon. Since your Jeep already has a 4-way like the T-One Vehicle Wiring Harness # 118786, there is only one other part you will need: - Universal Installation Kit for Trailer Brake Controller # ETBC7 This will give you a 7-way connector, circuit breakers and the rest of the hardware needed to install a brake controller. The face of the 7-way does have a plug-in for a 4-way as...

view full answer... - Install Harness for Prodigy P3 Brake Controller in 2022 Jeep Gladiator with OEM Tow PackageHey Kenneth, to install your Prodigy P3 part # 90195 in your 2022 Jeep Gladiator the correct install harness you'd need is the # 3073-P. How did you like the p3?

view full answer... - Availability of Wiring Adapter for 2020 Jeep Gladiator Using Kelsey Brake ControllerHi John; we don't have a brake controller wiring harness specific to your Kelsey 81741 so you can use the Tekonsha Custom Wiring Adapter for Trailer Brake Controllers - Jeep # 3073-P. You can cut off the end like you said and splice it together with your Kelsey wires. You can't always trust wiring colors but in this case the colors will match.

view full answer... - Recommended Trailer Brake Controller For a 2023 Jeep GladiatorI recommend the Redarc Tow-Pro Elite Brake Controller # RED63RR for your 2023 Jeep Gladiator. The Wiring Adapter # 3073-P will allow you to connect this controller directly into your factory wiring. This Redarc controller allows you to switch between proportional brake activation which is best when driving on road or a user controlled mode which comes in handy if you do an off-roading with your Gladiator. It also uses a small dash mounted control knob so you do not have a large control...

view full answer... - Recommended Trailer Brake Controller For 2021 Jeep Wrangler 4xe Hybrid With Regenerative BrakingFor your 2021 Jeep Wrangler 4xe I recommend the Tekonsha Prodigy P3 Trailer Brake Controller # 90195. This brake controller will give you proportional braking which automatically adjust braking force to your Flagstaff based on how hard or light the brakes are applied. A Tekonsha Custom Wiring Adapter # 3073-P will allow you to plug into the factory connector on your Wrangler that has the tow package. When you apply the brakes on your Wrangler 4xe the computer will calculate how much of...

view full answer... - How To Install Brake Controller On 2018 Jeep JL Without Access To Cold Side Of Brake SwitchIf the 2018 Jeep JL Wrangler has a factory tow package you can just use a Tekonsha Brake Controller p3 part # 90195 with a brake controller harness part # 3073-P to install a brake controller in the Jeep. The harness will plug into a port under the dash and you will not need to worry about hard wiring to the cold side of the brake switch. If your 2018 Jeep JL Wrangler did not come with a factory tow package, you can install a brake controller two different ways. The easiest way is to...

view full answer... - Brake Controller Plug-and-Play Harness For 2020 Jeep GladiatorThe Tekonsha Custom Wiring Adapter - Jeep # 3073-P is the product you're looking for. This adapter plugs into the 5-pin connector on your vehicle's built-in brake control wiring harness. The harness is located underneath the dash, to the left of the steering column, taped to another harness near the emergency brake pedal. This product is all you need as long as your 2020 Jeep Gladiator is equipped with the factory towing package. This adapter requires no cutting or splicing of wires...

view full answer... - Wire Harness Required to Install Redarc Tow-Pro Elite Brake Controller On a 2020 Jeep GladiatorFor your 2020 Jeep Gladiator with the factory tow package you will only need the Plug-and-Play Wiring Harness # RED93RR to attach the Redarc Tow-Pro Elite Trailer Brake Controller # RED44FR. This harness will have 2 connectors, one for the Jeep side and one for the Redarc. The Redarc Tow-Pro Elite Brake Controller for Tekonsha Harness # RED63RR that you found does require the Tekonsha Custom Wiring Adapter # 3073-P so you will have 2 different adapters to connect the controller making...

view full answer... - Recommended Trailer Brake Controller For a 2022 Jeep Gladiator With Factory Tow PackageI recommend using the Redarc Tow-Pro Elite Brake Controller # RED63RR with your 2022 Jeep Gladiator. You will use the Plug and Play Harness # 3073-P to connect to the tow package factory wiring on your Jeep. I prefer the Redarc as it hides the main unit behind the dash with only the small control knob visible on the dash. This controller also allows you to select from either a proportional mode which is best for towing on road or the user controlled mode which is best if you take your trailer...

view full answer... - Availability of Aftermarket Trailer Hitch with 7,000 Pound Capacity for 2020 Jeep Gladiator RubiconThe only aftermarket hitch available for your 2020 Jeep Gladiator Rubicon with the automatic transmission is the Curt Class III Receiver Hitch # CU74FR. This hitch only has a maximum gross trailer weight of 5,000 lbs. Unfortunately, the # DR64FR will not fit the Rubicon model. From what I have found, your only real option is going to be the factory hitch which fits your Jeep and has the capacity you're looking for. After recently towing a 7,000 lb travel trailer with a Jeep Commander...

view full answer... - How to Install a Brake Controller on a 2020 Jeep Wrangler Unlimited with a Factory Tow PackageWe have a very good solution for your problem! With the factory tow package you can use Tekonsha Custom Wiring Adapter for Trailer Brake Controllers - Jeep part # 3073-P this custom adapter allows you to plug in directly to the existing port under your dash and have the functions you need for your brake controller. At that point you just pick the brake controller you want and hook it up. With that connector any Tekonsha brake controller will plug right in. I would recommend using Tekonsha...

view full answer... - Recommended Trailer Brake Controller For 2022 Jeep Wrangler Unlimited With Factory Tow PackageI recommend the Redarc Tow-Pro Elite Trailer Brake Controller # RED44FR for your 2022 Jeep Wrangler Unlimited Rubicon. This brake controller has a very small foot print that will only take up a small portion of your dash. It is easily operated manually by simply pushing the button when you are towing your trailer. The controller is also proportional so it will adjust braking pressure on your trailer brakes to match the amount of braking force applied in the Jeep. For a plug and play installation...

view full answer... - Parts Needed and Instructions for Installing Brake Controller on a 2019 Jeep Wrangler UnlimitedWe have everything you need to get a brake controller installed on your 2019 Jeep Wrangler Unlimited. If you don't already have a brake controller I recommend checking out the Redarc Tow-Pro Elite # RED44FR because it takes up little to no room in your dash area and it has both proportional and user-control braking options which give you the best performance whether you're towing on the highway or going off-road. The parts you'll need to get this installed depend on if you have the factory...

view full answer... - Recommended Brake Controller & Harness for 2022 Jeep Gladiator With Factory Tow PackageYes, we have just what is needed for your 2022 Jeep Gladiator. I recommend the Tekonsha Prodigy P3 Trailer Brake Controller, # 90195 and use the Tekonsha Custom Wiring Adapter for Trailer Brake Controllers - Jeep, # 3073-P. This adapter plugs into the 5-pin connector on your Jeep Gladiator's built-in brake control wiring harness and located underneath the dash on the left of steering column. This adapter requires no cutting or splicing of wires to install. The P3 is a traditionally mounted...

view full answer... - Best Brake Controller for a 2022 Jeep Gladiator with Tow PackageThe brake controller that I recommend for your 2022 Jeep Gladiator with tow package is the Tekonsha Prodigy P3 Trailer Brake Controller # 90195 which will use the Tekonsha Custom Wiring Adapter for Trailer Brake Controllers # 3073-P to plug into your Gladiator. The # 3073-P will plug into the # 90195 and then the other end will plug into the port under your dash, providing for a plug-n-play installation. This will give you proportional braking for your trailer with one of the most reliable...

view full answer... - Can I Mount the Prodigy P3 On Top of the Dash?The Tekonsha Prodigy P3 Trailer Brake Controller # 90195 can be mounted anywhere on, in, or below your dash so long as it is horizontally level and parallel with the direction of travel. You will be able to use the Tekonsha Custom Wiring Adapter for Trailer Brake Controllers item # 3073-P to install the P3 without cutting or splicing wires. You will need to be creative with running the wires but so long as it is orientated the correct way you can do whatever you want. I have linked...

view full answer... - Brake Controller Install on 2021 Jeep Wrangler UnlimitedThat is correct. If your 2021 Wrangler Unlimited has the connector located under the dash to the left of the steering column near the top of the e-brake pedal as shown in the provided photo, you'd use the # 3073-P harness to connect the # 90195 Tekonsha P3 to the connector under the dash. You'd want to sever the blue wire exiting the rear of the controller and connect it to the blue output circuit you ran from the MOPAR 7-way you installed. This assumes that the connector under the dash...

view full answer... - Parts Needed to Install 7 Way Connector on 2020 Jeep Wrangler JL or JLUWe've got just what you need. If you don't already have a 4 way connector on the back of your 2020 Jeep JL you'll first need to install that using the Tekonsha T-One Wiring Harness # 118786. This harness will tee into your Jeep's tail lights and provide you with the starting point for installing a 7 way connector. If you've already got a 4 way, you're halfway there. For a 7 way connector you'll want to use the # ETBC7, which will utilize the wiring already in place (or newly installed...

view full answer... - Brake Controller Installation on 2021 Jeep Wrangler Unlimited With Factory Tow PackageActually, since your Wrangler Unlimited is equipped with the factory tow package, it will have the brake controller connector under the dash. The install is something you'll be able to complete yourself with ease as it's a plug and play install. The connector is located under the dash to the left of the steering column, near the top of the emergency brake pedal as shown in the provided photo. Rather than the time delayed Activator IV # 5504 you'd looked at, I'd recommend a proportional...

view full answer... - Quick Connect Brake Control Harness for 2020 Jeep Wrangler JLCurt doesn't offer a plug-and-play harness for the 2020 Jeep Wrangler with the tow package, but I DO have a solution for you. You'll need to use the Tekonsha version of the harness, part # 3073-P. Cut off the black connector on the # 3073-P harness, and cut off the black connector on the Curt # C49UR Assure brake controller, and wire the controller to the harness, color for color. You'll still retain the quick disconnect function. The # 3073-P harness plugs into the factory connector located...

view full answer... - Custom Brake Controller Adapter for a 2024 Jeep Wrangler w/ the Tow Package Yes, we do! To connect your Prodigy P2 Brake Controller item # TK68ER to your 2024 Jeep Wrangler JL Rubicon with the tow package you'll need the Tekonsha Custom Wiring Adapter item # 3073-P. The plug you're looking for is located underneath the dash, to the left of the steering column, taped to another harness near the emergency brake pedal.

view full answer...

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.