Deka Heat Shrink Butt Connector - 22-18 Gauge - Nylon Insulation - Red - Qty 5

- All Info

- Reviews (1104)

- Q & A (0)

- Videos (1)

- Photos

Deka Wiring - DW05743-5

Highlights

- Reliable connection for 22-18 gauge wire: Ensures secure joinery for electrical projects.

- Heat-shrinkable nylon insulation: Offers flexibility and long-lasting durability.

- Ideal for marine and trailer use: Withstands harsh conditions and provides a water-tight seal.

- Multi-purpose functionality: Perfect for crimping and heat shrinking in one step.

- Comes in a pack of 5: Handy quantity for small to medium wiring tasks.

- Distinct red color: Easily identify the right connector for your specific gauges.

Features to know about

Strong and Secure Connections: Heat-Shrinkable Nylon Insulation

Creating durable, lasting connections in automotive or trailer wiring projects can be a challenge. The Deka Heat Shrink Butt Connectors offer a robust solution. With heat-shrinkable nylon insulation, these connectors ensure your 22-18 gauge wires stay securely joined, providing both flexibility and superior durability. No more worrying about wires slipping out or damage from the elements.

Weatherproof Your Wiring: Waterproof Heat Shrink Feature

When you're working in environments exposed to weather, like trailers or boats, you need a solution that stands up to the elements. The Deka connectors are equipped with a heat-shrink feature that, when applied, creates a tight, waterproof seal around your wires. This means your connections are not just protected from water but also from dirt and grime, ensuring longevity and reliability.

Easy and Efficient Installation: Crimp and Shrink Design

Say goodbye to complicated wiring fixes that take hours. With these connectors, the crimp and shrink design simplifies the installation process, making it quick and straightforward. Even if you're not a wiring expert, these connectors make easy work of creating professional-grade wiring connections. Perfect for both first-timers and seasoned DIYers.

Limitless Wiring Projects: Versatile Application

Whether you're refurbishing an old trailer, installing new LED lights on your boat, or simply tackling a small repair job, the versatility of these connectors cannot be overstated. They fit seamlessly with any 22-18 gauge wire, making them an essential tool in your wiring kit for numerous applications.

Essential for Critical Repairs: Reliable Hold for Long-Term Use

You want peace of mind knowing your connections are firm and lasting, especially when handling critical wiring tasks like trailer lights or brake systems. These connectors offer a reliable hold that withstands vibrations and movements over time, so your project remains intact long after the repair is complete. A simple but effective solution for ensuring long-term performance and safety.

05743 Deka Butt Connector - 22-18 Gauge - Nylon Insulation - Red - Qty 5

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Video Transcript for Deka Butt Connectors Detailed Breakdown

Hey, everyone, Ryan here at etrailer. Today we're gonna be checking out the line of Deka heat shrink style electrical butt connectors. Now these are available in a variety of different sizes. So you have the red, the blue and yellow, so small, medium, large if you will. And you can also pick these up in different amounts. You can get 'em individually, as a five pack, or even a 10 pack.

With these heat shrink connectors, what they're gonna allow you to do is pair two wires together, right, and make a a complete circuit. And we'll show you how to do that a little bit later on with these. But these are my go-to whenever I need to make a connection like that. These are what I always grab, especially if the wiring is gonna be outside or in harsher elements. And I say that because the ends of these heat shrinks will seal up, and actually kind of wrap around the wire, and help prevent moisture and stuff like that from getting inside of that connection and causing corrosion.

So if you're looking for, you know, the ultimate protection, so to speak, and help keep your wiring connections in good shape, then something like this is what I'd recommend. Now with that said, there are more standard type butt connectors like these ones here, all right And these, when you crimp 'em down, they don't have that heat shrink on it, right So the ends don't seal, and that'll leave little portions of the inside of the connector exposed, and that's what can happen. Corrosion and moisture and stuff can get in there and start to break it down and deteriorate. Now that's not to say these don't have time and a place because they do. If I'm ever doing stuff on the inside of a vehicle, or where I'm not really too concerned about, moisture and things like that, then by all means, these will do the job just fine.

Now, what size butt connector you're gonna need is this really gonna depend on your application, right So I talked about there being three different sizes. The yellow one's gonna be the largest, that's gonna be for 10 to 12, all wire gauge type wiring. So relatively thick stuff. Something like this is where you would use the yellow connector there. So pretty thick wire.

For the blue one, that's going to work with 14 to 16 gauge wiring, something like this, right More on the medium thickness side of things. And for the red one, it's gonna be the smallest, it's gonna be from 22 to 18, all wire gauge. And when you're dealing with wire, the higher the number, the thinner the wire is, right So for example, 18 gauge would be thicker than 22. Just figured I'd share that. So with these, you know, pretty thin wire, that's what you're dealing with there. And sometimes if you're unsure what you got, a lot of times if you look closely on the wire, they'll be labeled what it is. So this one says 20 AWG, so we know that's 2020 gauge wire, and we need to use the red connectors to complete connections with this type. Now that you know how to determine what size connector that you're gonna need, how many are you gonna need, right Now good rule thumb that we always talk about is always get more than enough, right Because you know, no matter how many times you count what connections you got and stuff, it never fails, right You always need an extra one or something happens. And honestly stuff like this anyway, if you do happen to have a few leftover, they're not bad to have laying around, you'll probably find yourself needing 'em in the future for one reason or another. That's really about it with these. You know, ultimately if you're doing wiring that's going to be exposed to the elements, no brainer, use heat shrink style connectors, will keep it protected and make the connection last longer. Now everyone's gonna use these for a variety of different reasons, right They're super universal, cars, trailers, all kinds of stuff, right Today we're using these to do some wiring on the trailer, make a repair, put a new end on it. And so why don't we go ahead, show you how we set ours up and give you a good idea on how to use these on your particular application. Very first thing that we need to do is take the wires that we're gonna be working with and making our connections to, and strip the ends of the installation back. So about like that is what you're looking for, maybe even a little bit shorter. But you then want to twist the wire nice and tight. That'll give us a good connection, and I'm just gonna make that a little bit shorter there. And then you take your butt connector, in this case we're gonna be using a blue one for this size wiring. Slide that over the bare end of the wire. And what I try to do is make it to where when you put the connector on that bare end of that wire, that's where it stops. You know, that way all the wiring is inside of the metal connector there. We'll take a pair of crimps, get this in, crimp down. You can lightly pull on it if you want to, to make sure it's not just gonna fall outta there, which it's good. Then we'll complete our connection here. All right, taking the other end of the wire that we're hooking this up to, putting it in there, and crimping it down. Going to do that same thing for our yellow wire here. Get that attached. And then for these brown wires, so in our case, we have one brown wire for our new trailer connector, right But we have two brown wires for our trailer and these are both taillight signals and this is too. So what we're gonna do, this is perfectly fine to do so, is just twist these two ends together, get 'em nice and tight. And then we're gonna step up one size to a little bit larger butt connector, put that over both ends of the wire, crimp it down. And then for, since we're gonna be putting one end, one wire end on the other side, what I like to do when this happens, is strip the wire back a little long and then double it over. That'll help the butt connector get a little bit better of a bite onto it. Got that connection made. And now we're ready to shrink the ends down. And so in order to do that, I recommend using a heat gun. And you apply heat to these, you know, kind of just consistently move it around. Try not to keep it in one single spot for too long. (heat gun humming) So that's about as long as you need to keep that heat onto it right there. Once it shrinks down and stop shrinking, that's really all the heat that you need to apply to it. You don't just want to keep it on there and continue to warm it up if we don't have to. So hit these other two and should be good. (heat gun humming) Once you have all of your connections made, it's not a bad idea to actually test everything out to make sure that the connections are indeed good. So being that we're dealing with trailer wiring today, in our case, I just hooked up to a little test box, which is simulating a vehicle, turn our lights on, and make sure power to the back where they're mounted up. We'll track our taillights, our left turn, our right turn and our brake lights. With everything working, you know the connection's good. And then if you want to, you can always come back with electrical tape too and tape these up for an additional layer protection. But with that said, I think that'll about do it for our look at of the line of Deka heat shrink style butt connectors.

Ratings & Reviews

4.8

996 reviews

See what our Experts say about this Deka Wiring

- How to Use a Taillight for Both Third Brake and Running Light FunctionsIn order to use a third brake light for both brake and running light signals, you would need to use a light with turn, brake, and running light capabilities such as the Thinline LED Trailer Tail Light part # STL59RB. As most trailers are a 3 wire system you would also need to use the Vehicle to Vehicle Tail Light Converter part # 118158 to separate the brake signals from turn the signals. In order to install the light you would first need to take the ground wire (white) from the taillight...

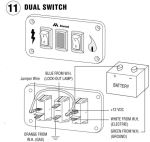

view full answer... - Wiring An Atwood RV Water Heater With Double-Panel On/Off SwitchThe manual for the Double-Panel On/Off Switch for Dometic Gas / Electric Combination Water Heaters - White # AT91230 lists the wire as orange but the manual for Atwood water heaters like AT94022 list the wire as red. It's referring to the wires that come out of the top of the unit. The three dash symbol you're referring to means ground. The blue wire will connect to terminal 6 of the switch. Terminal 4 of the switch will go to the negative battery terminal. The green wire will connect...

view full answer... - Installation of Dual Switch on Suburban Brand Water HeaterYou can absolutely install a double switch like the Replacement Double-Panel On/Off Switch for Atwood Gas and Electric Combination Water Heaters - White # AT91230 on your Suburban Water Heater. This switch when wired correctly will allow you to power the gas burner and electric components independently. I've attached a wiring diagram to assist. You may want to use the Female Spade Terminal Quick-Disconnect # DW01899-1, butt connectors # DW05743-5, and Deka Ring Terminals # DW05737-1.

view full answer... - Recommended Wiring Harness to Rewire a Utility Trailer Hey David! To rewire your Leonard Utility Trailer you'll want the 20 Ft 4-Way Trailer Wiring Harness item # A20WB. This will replace your utility trailer's 4-way connector and all of the wiring back to your tail lights. This wishbone-style harness comes with 2 tail light wires split for simple wiring. You shouldn't have to use any connectors like item # DW05743-5 until you get to your tail lights.

view full answer... - What Size Butt Connectors are Needed for the Optronics LED Combination Trailer Lights The wire leads on the Optronics LED Combination Trailer Lights # TLL160RK are 20 gauge, so you'd need to use the Deka Heat Shrink Butt Connector # DW05743-5.

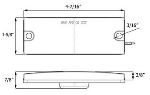

view full answer... - Recommended Replacement Tail Lights w/ License Plate Bracket Hey Gary! The Bargman lights you referenced are out of stock but I have a close alternative. They are the ONE LED RV Combination Tail Light w/ License Plate Bracket item # RVSTLB0061 and the Passenger Side item # RVSTLB0060. These lights measure 8-5/8" long x 3-3/16" tall x 2-1/4" deep, with the mounting holes being 7-3/8" apart horizontally and 1-7/8" apart vertically. Both lights are a 3-wire design, with stop, turn, tail, and ground functions. You can connect them with the 5-pack Deka...

view full answer... - Can the Connector Be Cut Off on the LED Clearance and Side Marker Trailer Light MCL35A32G?Yes, it can! The connector on the LED Clearance and Side Marker Trailer Light w/ Reflector item # MCL35A32G can be cut off and spliced into your trailer's wiring. I recommend using heat shrink butt connectors like item # DW05743-5. It is grounded by the mounting hardware.

view full answer... - Are Taillights STL8RGB and STL9RGB a Set? What Butt Connectors and Shrink Wrap do I Need?Hello Dave, Yes, the Combination LED Trailer Tail Light - Submersible - 6 Function - 11 Diodes - Passenger Side # STL8RGB is the better half to the Combination LED Trailer Tail Light - Submersible - 7 Function - 14 Diodes - Driver Side # STL9RGB. The lights use 20 gauge wire, so you will need a pack of the Deka Heat Shrink Butt Connector - 22-18 Gauge - Nylon Insulation - Red - Qty 5 # DW05743-5. When I rewired my boat trailer I went ahead and put Primary Wire Heat-Shrinkable Tubing...

view full answer... - What Gauge Wire Does The LED Trailer Clearance or Side Marker Light # 328-K-58LB Use?The LED Trailer Clearance or Side Marker Light # 328-K-58LB uses 20 gauge wire. For a Butt Connector I recommend the Deka Heat Shrink Butt Connector # DW05743-5.

view full answer... - Connecting Thule License Plate Holder # TH35JV To 4-Way Flat Trailer Connector WiringYes, you can use the Roadmaster Extension Loop # RM-300150-00 to connect to the Thule License Plate Holder # TH35JV wiring. This will leave you 2 exposed male terminals which will have power and could short out when using the turn signals and brake lights. You can protect this by covering the terminals with some Heat Shrink # DW05450 to seal away the connectors. Or so you do not have so many connections you can cut off the end connectors of the 4-way and 2-wire to connect them with Butt...

view full answer... - How to Install the On/Off Switch Panel for Atwood Gas and Electric Water Heaters Part # AT91230I have attached the wiring diagram for the Replacement Double-Panel On/Off Switch for Atwood Gas and Electric Combination Water Heaters part # AT91230. The installation will be very simply with only 5 connections needed. There will be three terminals that go to the water heater (orange, blue, white), one terminal that goes to a 12 volt power source, and one terminal that goes to a ground. In order to make these connections I recommend using four of the Female Spade Terminal Quick-Disconnect...

view full answer... - Wiring The B&W Headache Rack Into A 2021 Ford F-350 Super DutyThe B&W Custom Headache Rack with LED Lights # BWPUCP7500WA is designed so that the two innermost lights will serve as taillights while the two on the outside work as brake/turn lights. These lights are fed by bonded 4-pole wiring like what is typically found in a 4-pole wiring harness. Your easiest solution is going to be to install a 4-way on the end of the wiring harness that comes with the headache rack like the # HM48110 using some heat shrink butt connectors # DW05743-5 for a water...

view full answer... - How to Connect 5 Wires on Trailer to 4-Way ConnectorFor your application I recommend picking up the Wesbar Wishbone Wiring Harness with 4-Pole Flat Trailer Connector # 002402 because it has the 2 brown wires so your installation will be really simple. Just use heat shrink butt connectors like part # DW05743-5 for the standard wires and add a ring terminal like part # DW05737-1 for the ground wire. If you already have a 4-Way connector with just 4 wires then you'll combine the ends of the 2 brown wires and connect them to the running light...

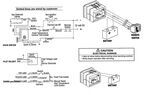

view full answer... - 7-Pin Agricultural Vehicle Connector To 4-Pin Flat Trailer ConnectorDue to your 7-pin connector not having combined tail lights and brake lights you will need to create an adapter using the following parts. The Pollak Heavy-Duty, 7-Pole # PK11700 will connect to your 2012 John Deere 5045d tractor. You will wire the Hopkins Tail Light Converter # HM48847 to this. The 5 wires from the converter will attach to the 7-pin connector as seen in the image below. Then you will be able to attach the Hopkins Endurance Easy-Pull Harness # HM48058 to the 4 wires on...

view full answer... - Determining Which LED Tail Lights For 1998 Ranger Trail Boat TrailerI may have an option, but unfortunately we do not have any LED tail lights that are exactly 6-1/2" x 2-1/2". Instead we have the Optronics Miro-Flex LED Trailer Tail Light - Stop,Turn, Tail - Submersible - 12 Diodes - Red Lens # STL22RBH which is 6-1/2" x 2-5/16" and is Sonically Sealed which will keep water from getting into the light making it a great option for a boat trailer like your 1998 Ranger Trail Boat Trailer. The # STL22RBH does have a plug so you will need the 3-Wire Pigtail...

view full answer... - Can 4-Way be Spliced Into Trailer That Has 7-WayIf you don't want to use a vehicle adapter like the Mighty Cord Trailer Connector Adapter - 4-Way Flat to 7-Way RV Style # A10-7084VP on your vehicle with a 4-way to adapt it to your trailer's 7-way, then yes, you can splice into your trailer's wiring to add a 4-way if your like. You can use the trailer side connector you mentioned, the Hopkins Endurance Easy-Pull Harness with 4-Pole Flat Trailer Connector # HM38136. To splice it you can connect your wires with the Deka Heat Shrink Butt...

view full answer... - Recommendation for LED Waterproof Corrosion Resistant Rescue Boat Trailer LightsSince your rescue boat trailer is 188 inches (15 feet 8-inches) tongue to tail and 89-1/2 inches (7-1/2 feet) width I recommend the following: I recommend Optronics right side LED trailer light # STL26RB and left side LED trailer light # STL27RB. They are waterproof and corrosion resistant and will mount to all surfaces. These work great with trailers over 80 inches wide. The left side has a built-in license plate light. The rear clearance and side marker red LED lights # MCL13R2B are...

view full answer... - Dimensions and Wiring Identification For Rotary Dimmer Switch # 37215235The Rotary Dimmer Switch # 37215235 is 3-9/16" tall, and 2-3/16" wide. The cutout section is 2-9/16" tall and 1-3/4" wide. The red wire is for connecting to your 12 volt positive power source while the white wire leads to the positive terminal on the light fixture. The ground wire will connect straight to the battery or other 12 volt ground source. When replacing your switch you will be able to tie your negative wires together at the switch to complete this circuit. Be sure to use a connector...

view full answer... - Replacement Tail Lights For a 2011 Venture Boat TrailerThe Wesbar Low Profile Trailer Tail Light 403026 is the same size and type that you currently have on the drivers side of your 2011 Venture Boat Trailer. This is an incandescent light and there is the matching Passenger Side 403076. While neither of these have the plug style connector you have on your trailer you can cut the wiring on the light side and attach them using the Deka Heat Shrink Butt Connectors # DW05743-5. We also have LED tail lights you can upgrade to if you want to have...

view full answer... - Replacement Wiring on Bully Lighted Hitch StepTo replace your wiring on your Bully hitch step # CR-600LED I recommend the Hopkins Wiring Harness with 4-Pole Flat Trailer Connector # HM38138 along with heat shrink connectors # DW05743-5. For added protection you can add a wire loom like # 7509-1 sold by the foot. The wires of this harness have the following functions for you to match up to the wires in the step. White: ground wire Yellow: left turn/brake light Green: right turn/brake light Brown: tail lights

view full answer... - How To Fix Power Wire On Voyager WiSight Backup Camera That Was CutThanks for the picture! Based on the picture you sent in you may have enough room to use heat shrink butt connectors # DW05743-5 to reconnect the cut wires. There should be one black wire, and one red wire. You will need to strip back the jacket on the wires, reconnect them using the # DW05743-5, and then can use black electric tape # PP47FR to cover the connections to make it blend in.

view full answer... - Replacement Tail Lights For 2019 Coachmen Freedom Express Select 23.9 SE Travel TrailerThanks so much for your photo and you will need to replace the entire assembly. Based on your photo and the approximate length, we do have replacement tail lights for your 2019 Coachmen Freedom Express 23.9 SE travel trailer, and I'll list both the driver and passenger side: - Driver Side: ONE LED RV Combination Tail Light w/ License Plate Bracket # RVSTLB0061 - Passenger Side: ONE LED RV Combination Tail Light # RVSTLB0060 These lights measure 8-5/8" long x 3-3/16" tall x 2-1/4" deep,...

view full answer... - How Do I Re-Wire My Pop-Up Trailer To A 4-Pole Trailer Connector?

TheyIn order to wire your pop-up trailer with a 4-pole wiring harness like the 35 Ft 4-Way Trailer Wiring Harness - Wishbone Style # A35W42B, you're going to first have to: 1. Connect the white ground wire to your trailer's frame. You'll want to make sure that the spot you choose for grounding is a clean, bare, surface that is free from rust. You'll use the already attached ring terminal, as well as a self-tapping screw # 101131802. Before you secure your ground wire, be sure to leave the...

view full answer... - Red & Amber Side Marker Lights and Clearance Lights. LED and Easy ReplacementWe have some excellent replacements for your clearance lights. For amber/yellow I recommend the Optronics # MCL82AB LED clearance light, and for red I recommend the Optronics # MCL82RB light. These two options are identical excepting color. They have LED lights that are bright and will last far longer than traditional incandescent lights. The screw mounting holes are exactly 4” apart like you current ones, so this will be a quick and easy swap out. The other measurements are with in...

view full answer...

Do you have a question about this Wiring?

Info for this part was:

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.