To see if this custom-fit item will work for you please tell us what vehicle you'll use it with.

This time-delayed brake controller is designed to mount at any angle, even upside down. The controls are all up front for easy access, including a slide-bar manual override and a thumbwheel for braking output. LED indicator shows your braking status.

Features:

Specs:

The Tekonsha POD is designed to mount in any direction, and it's especially suited for mounting on near-vertical dashes. All the controls are on the front of the module, so you can still access them with the controller tucked away in a convenient place.

Braking output is the maximum amount of power that will be applied to your trailer's brakes. How much braking output you need is determined by the weight of your trailer; a heavier trailer will need more power to bring it to a stop. You want to set the braking output as high as you can without locking up the brakes. Once you've set up the brake controller the first time, you shouldn't need to adjust the settings until the trailer load changes, you switch trailers, or road conditions change. Use the thumbwheel on the side to change the braking output level. The output setting will appear as a number on the digital display, with a higher number indicating higher braking power.

The Tekonsha POD keeps the manual override within easy reach on the front of the module, great for stopping sway or controlling your trailer's momentum in emergencies. Push the slide-bar lever to activate the trailer's brakes and brake lights without you having to apply the brakes on your tow vehicle, perfect for limiting trailer movement while you're cruising.

Because inertia plays no role in the functioning of this controller, you do not have to mount the unit at any particular angle. Your mounting options are limitless, with the controller designed with all of the controls on the front of the module so you can access them even if it's mounted upside down.

The included custom adapter easily plugs into the built-in port in your vehicle. Once you have the wiring connected to your vehicle, just plug the other end into the POD. Because there are no wires to splice, installation is not permanent. You can unplug and remove the brake controller at any time and securely stow it away.

Note: If you don't already have a 7-way plug at the back of your vehicle, take a look at our exclusive 7- and 4-way brake controller installation kit (ETBC7 - sold separately).

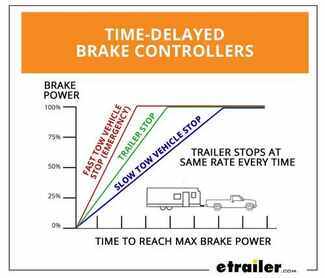

The Tekonsha POD comes equipped with time-delayed braking. Every time you apply the brakes in your vehicle, a signal is sent - via the brake switch - to the POD. The controller then sends power out to your trailer brakes to activate them with an intensity set by you, at a rate determined by you. The amount of braking power (output) can be adjusted to suit your preference, the road conditions, the type of trailer, and the weight of your load. To determine which levels are best for your application, test your towing setup and choose what feels right.

California residents: click here

Videos are provided as a guide only. Refer to manufacturer installation instructions and specs for complete information.

Hey everybody, Ryan here at etrailer. Today, we're gonna be taking a look at the Tekonsha PowerTrac Brake Controller. So, this will be a real good choice for those of you that are maybe just replacing an older brake controller and just wanna stick to something simple. And that's for a brake controller like this one's gonna come into play. What this is gonna do, is send power after your trailer's brakes and help keep everything safe. One of the things I like about this one is kind of how it's styled actually.

It's just a little bit different. It kind of has some different angles going on here and the face of it is flat. It's just really user-friendly. It's easy to see what's going on and easy to reach everything. You know, it's something small but goes it a long way in terms of having to live with it and use it, you know.

I'd say it's probably, overall size, it's probably medium. You know, there's some smaller, more compact ones like the Draw-Tite I-Command, for example. And then there's some little bit larger ones like the Tekonsha P3. So, it kind of falls somewhere in the middle. The thing is with this one, it is a time-delayed brake controller.

And so what that means, is it's gonna have a preset amount of power that is sent back to your brakes whenever you hit your brake pedal in your vehicle here. You know, that has some benefits and some downsides to the more modern proportional type brake controller. One of the benefits is, of the time-delayed is, you know what to expect. You know, you have the complete adjustability of how much power you wanna send back there. But you know, one of the advantages the proportional one has it's a little bit smoother, you know smoother of an experience, generally speaking.

You can usually fine-tune the time delays and be really happy with it. But just to kind of throw a brake controller in and go a proportional one's usually a little bit better. What they do is match the breaking pressure of your 4Runner. So let's say, if like you're barely hitting the brakes in here, about halfway, trailer brakes are gonna do the same thing. On the other hand, let's say emergency stop, right So you really gotta stand on that brake pedal, trailer brakes gotta do the same thing. So it's hard to argue with that, you know what I mean It's gotta match that pressure and be really predictable. So, in terms of actually living with this, I mean, super simple, you're gonna have one adjustment so you're gonna have a dial here, and you can either dial-up or dial-down the breaking intensity. So obviously when you go up and hit your brake or we'll use the manual override, just kind of amplifies a little more. You can see the color is going to indicate to you how much braking power is being applied. So green and, you know, yellowish-orange, that's light power the more power that's applied, it's gonna turn into that deep red. And that deep red is letting us know, that we have maximum power going back there. So, one of the things that you can do, whenever you get your trailer, is hook up to it, you can hit your brake pedal and dial that knob up till about orange, you know, about somewhere in the middle kind of go from there. If you feel like the breaking power's not strong enough, if the trailer's kind of wanting to push you around or you feel your car kind of struggling, you know you can always dial that up some and amplify it. If it's too much, if the brakings' too aggressive, just dial it down some. So, like I talked about earlier you can adjust this pretty good. So, you know, you find something you're happy with and you go, "All right, I'm just gonna bump it up a little bit more, see how it feels." And you can really dial that in, to your liking. And I feel like, that's why this is a pretty popular brake controller. You know, it's just so simple. I mean, anyone can figure this thing out. One of the things though, you know, nowadays there's so many of 'em available and some of them are really neat. You get a ton of options and crazy adjustability, like the P3 by Tekonsha, for example, you can do all sorts of wild things with it. You know those ones with all the bells and whistles are really kind of targeted towards people that use 'em for a living, you know, and really rely on all those different options. Something like this vehicle, you know, if you pull the same trailer, maybe two, this is gonna get you going down the road just fine. And, you know, I do just want to give you an option, maybe you don't like the look of the traditional style brake controller, where it's mounted on the dash, you know, and I don't blame you. There is options out there. One of 'em is the REDARC, and essentially the main body of the brake controller is hidden up underneath the dash where you can't see it. And the control is simply just a small knob. And it's actually really cool, I've done several of them. That's always an option for you as well. But, other than that at the end of the day if you're looking for something simple that's gotta work and you can rely on, can't really go wrong with this brake controller. And that'll finish up our look at, the Tekonsha PowerTrac Brake Controller..

Do you have a question about this Trailer Brake Controller?

Info for this part was:

At etrailer we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.

Thank you! Your comment has been submitted successfully. You should be able to view your question/comment here within a few days.

Error submitting comment. Please try again momentarily.