Tips on How To Tow a Trailer

Equipment Capacity

Trailer Loading

Driving

Gradually reduce speed Steady the steering wheel - sudden turns can cause more sway Apply only the trailer brakes to help reduce trailer sway

Do not slam on the brakes - jackknifing could occur Do not attempt to steer out of a sway situation Do not increase speed - trailer sway increases at faster speeds Do not tow a trailer that continues to sway (consider reloading the trailer or perhaps adding sway control or a weight distribution system with sway control).

Trailer Towing Components

Trailer Hitches

Ball Mounts

Hitch Ball

Gross trailer weight (GTW) Hole diameter on the ballmount Ball mount platform thickness Trailer coupler size

Safety Chains

Trailer Wiring

Electric Trailer Brake Controller

Trailer Couplers

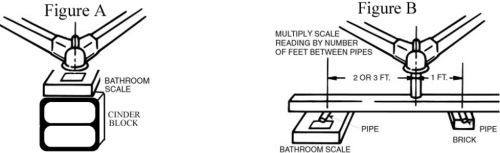

Weight Distribution

Sway Control

Trailer Tires

Towing Mirrors

Transmission Coolers

Trailer Bearings, Races, and Seals

David C.

8/5/2021

I have: 2009 Honda Element EX with a class I hitch (no ball). I eventually want to be able to tow a trailer with a boat that do not exceed my 1500 lb capacity. Could you please help me figure out what I need to purchase (including a class II or III hitch if required) in order to do this? Thanks very much.

John H.

6/3/2021

I was shocked when I was recently told by a supposedly knowledgeable source that trailer GVWR does not include tongue weight. Is this true?

Kelly P.

3/31/2021

Im planning on pulling my 18 ft trailer behind a dodge caravan. Can you tell me of this will work.

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

Margaret E.

9/13/2021

My Scamp has a small refrigerator. Can my car battery cool the camper refrigerator while I'm driving? If so, should I turn the electric switch on my camper on or off? Thank you.