Single point anchors Moveable anchors clamp to pickup trick or trailer rails and can be positioned anywhere along the rail. Stake pocket anchors mount in pickup truck stake pockets to create an easy-to-access tie-down point. Cleats attach to a flat surface and provide a tie-down point for rope. They usually have a ring for attaching the free end of a rope, or they have an open hook over which you can attach a rope that has a loop at the end. Surface mount anchors and recessed anchors attach to the surface of a truck bed or trailer and have D-rings that fold or retract out of the way when not needed.

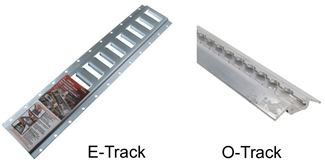

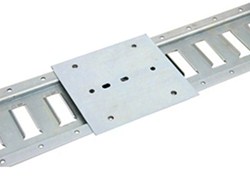

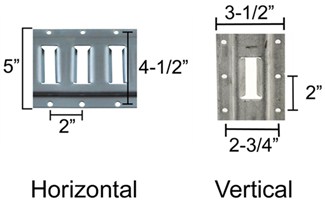

Track systems E-Track systems are available as strips of track or single anchor points and can be mounted on flat surfaces of trucks or trailers, even inside enclosed trailers - anywhere you need anchors. Each track consists of a row of slots that receive special, snap-in connectors. You can attach the connector of your tie-down to any convenient slot in the E-track. Many types of tie-downs work with E-track connectors. O-Track systems are similar to E-track, in that they consist of strips of track that can be mounted on any flat surface, creating a row of anchor points for the tie-downs. Special connectors attach quickly and securely to the track. You can slide them along the track to the most convenient location. Each connector provides a metal loop that can accommodate many styles of tie-down hooks.

Departments

Towing

- Trailer Hitch

- Fifth Wheel

- Gooseneck

- Towing a Vehicle

- Front Hitch

- RV Hitch

- ATV Hitch

- HD Truck Hitch

- Vehicle Wiring

- Brake Controller

- Ball Mounts

- Weight Distribution

Sports and Recreation

Trailer Parts

- Utility Trailer

- Boat Trailer

- Landscape Trailer

- Enclosed Trailer

- 5th/Camper Trailer

- Car Hauler

- Horse Trailer

Vehicle

Contact & Help

What our customers are saying:

"In these days of customer "no service" I am usually disapointed when doing business with people I don't know. It was refreshing doing business with you. I'm impressed!"

Randy

Watkinsville, GA