2001 Lexus RX 300 Trailer Hitch

Curt Trailer Hitch Receiver - Custom Fit - Class III - 2"

Trailer Hitch Size:

2 Inch Hitch Opening

Towing Capacity:

350 Pound Tongue Weight

3500 Pound Towing

Trailer Wiring:

2001 Lexus RX 300 Trailer Wiring

With tow package use C55245 for wiring

Features:

This fully welded trailer hitch receiver bolts onto your vehicle's frame with no welding required. Powder coated steel is sturdy and corrosion resistant.

Installation Notes:

No drilling through vehicle frame required for installation

More Information > Draw-Tite Max-E-Loader Trailer Hitch Receiver - Custom Fit - Class III - 2"

Trailer Hitch Size:

2 Inch Hitch Opening

Towing Capacity:

350 Pound Tongue Weight

3500 Pound Towing

Trailer Wiring:

2001 Lexus RX 300 Trailer Wiring

With tow package use 118245 for wiring

Features:

Fully welded vehicle trailer hitch is strong and durable. Draw-Tite's Tested Tough guarantee ensures that this hitch exceeds industry standards. The combination of an e-coat base and a powder coat finish provides excellent rust protection.

Installation Notes:

No drilling through vehicle frame required for installation

More Information >

on Trailer Hitch

Videos

for Trailer Hitch

Help Articles

for Trailer Hitch

Expert Answers

for Trailer Hitch

The difference between the Class II and Class III hitches has to do with their Gross Trailer Weight (GTW), their Tongue Weight (TW), and their Hitch Receiver Size. Class II trailer hitch receivers have a 1-1/4 inch receiver and can be rated up to…

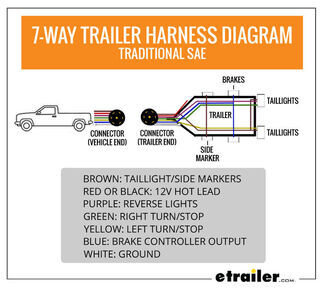

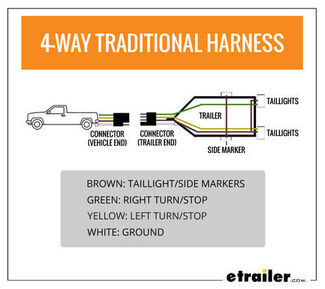

view full answer...A 4-Way trailer connector has the basic lighting functions only; running lights, left turn signal and brake lights, right turn signal and brake lights, and ground. A 7-Way has these functions and a 12 volt circuit, a circuit for electric trailer…

view full answer...The main difference between the Curt Trailer Hitch Receiver part #C13416 and the EcoHitch Hidden Trailer Hitch Receiver part #EH97FR is that the EcoHitch has a completely hidden cross tube whereas the Curt cross tube will be visible from the rear of…

view full answer...There is only one difference between the Curt Trailer Hitch Receiver #C13176 and etrailer Trailer Hitch Receiver #e98909 that fit your 2020 Chevrolet Colorado, which is the finish. The Curt trailer hitch has a glossy black finish while the etrailer…

view full answer...Hi Stephanie! Great question and you’re totally right to ask, because most hitches for the 2024 RAV4 do require a bit of bumper trimming. That includes the Oris Detachable Hitch #TS66VR, since it uses a hidden design that needs a hole cut in the…

view full answer...Yep, so long as your 2024 Subaru Crosstrek Wilderness is not a hybrid both the Curt and etrailer hitches will fit: - Curt Trailer Hitch Receiver #C13382 - etrailer Trailer Hitch Receiver #e98912 The only difference besides price is the finish; the…

view full answer...Though the Curt # C13409 and Draw-Tite #76271 are nearly identical to each other, there are a few subtle differences. First being where they sit once installed. The will both have the exact same height of 14-1/2 inches, but the Draw-Tite #76271 will…

view full answer...I definitely understand being a bit overwhelmed by the amount of options in front of you, however I can definitely help with differentiating the trailer hitches for your 2019 Subaru Outback Wagon along with explaining my personal recommendation,…

view full answer...Dana, it comes down to budget, capacity needs, and clearance when looking at hitch options for your 2024 RAV4 Prime. The Trailer Mate 2" Hitch #TMT54FR is the most affordable of the bunch and still gives you a clean, concealed look with 3,500…

view full answer...Hey Piotr, thanks for reaching out! The weight ratings between the Curt Trailer Hitch Receiver #C94WR and Towsmart Trailer Hitch Receiver #TS96VR that fit your 2025 Kia Sportage are determined by the testing done according to those manufacturers. I…

view full answer...Both the Curt #C13382 and the etrailer #e98912 hitch are a 2" Class III hitch receiver that will provide a maximum gross trailer weight of 3,500 lbs and a maximum tongue weight of 525 lbs. You are correct, they are an identical hitch but our…

view full answer...Hey Mike, so I checked with Curt and their hitch part number 13630 which is our part number #C33MJ does fit the 2025 Mazda CX-50 hybrid. Curt says this actually fits all models of the vehicle actually. What are you planning on using the hitch for?

view full answer...

Filters

- 2 results

Contact and Help

- Customer Service

- Contact Us

- My Orders

- About Us

- Privacy Policy

- Trailer Hitch Help

- Trailer Hitch Videos

- Your Account Login

What our customers are saying:

Great service- ordered hitch, $50.00 cheaper than local store & arrived in a week. Hitch fit perfect & took about 20 minutes to install- saved about $150.00 on parts & labor doing it this way. Great experience- highly recommended.

Rich

Pine Beach, NJ

Filters

Filters