Trailer Hub Inspection Demonstration Video

Products Featured in this Video

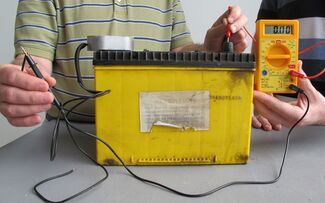

Demonstration of a Trailer Hub Inspection Including Brake Assembly and Bearings

We get many many questions on how to make sure trailer hubs and brakes are safe for travel. Here Joe addresses some of those questions demonstrating how to thoroughly inspect the hubs, breaks and bearings. I know many of us take the performance of these assemblies for granted but if you are planning a long trip or just make short trips around town you should be aware of their condition. I like to… see more >

Info for these parts were:

Video Edited:

Joshua S

Video Edited:

Chris R

Installed by:

Cole B

Installed by:

Ryan G

At etrailer.com we provide the best information available about the products we sell. We take the quality of our information seriously so that you can get the right part the first time. Let us know if anything is missing or if you have any questions.